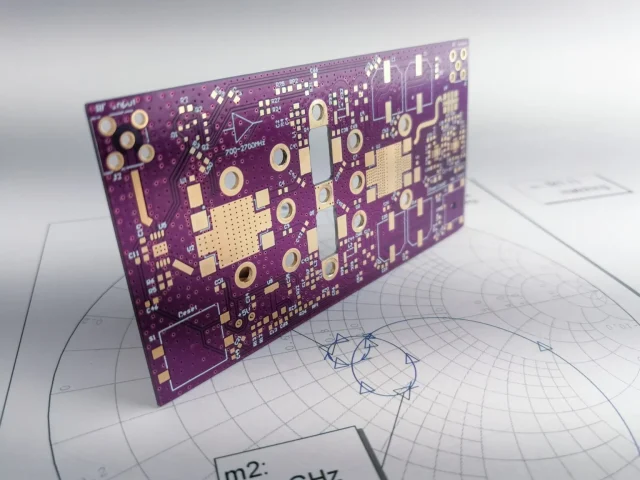

What Is a High Current PCB?

A High Current PCB is a printed circuit board specifically engineered to carry and distribute large electrical currents safely and efficiently. Unlike standard PCBs, high current PCBs utilize heavy copper layers, wide trace designs, and optimized thermal management to minimize power loss, prevent overheating, and ensure long-term reliability.

High current PCB solutions are essential in applications where stable power delivery and thermal performance are critical, such as power electronics, industrial equipment, automotive systems, energy storage, and charging infrastructure.

Why High Current PCB Design Is Critical

As power density increases in modern electronic systems, traditional PCB designs may suffer from:

-

Excessive heat generation and copper trace overheating

-

Voltage drops due to insufficient conductor width

-

Reduced system efficiency and reliability

-

Risk of thermal fatigue and PCB failure

A properly designed high current PCB ensures low resistance, efficient power transfer, and stable thermal behavior, even under continuous high-load conditions.

Key Design Considerations for High Current PCBs

1. Heavy Copper Technology

High current PCBs typically use thick copper layers, ranging from 2 oz to over 10 oz, to reduce resistance and improve current-carrying capability. Heavy copper construction ensures lower temperature rise and improved mechanical strength.

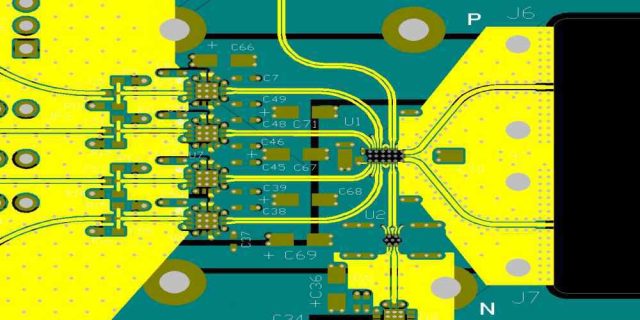

2. Wide and Thick Copper Traces

Optimized trace width and thickness are essential to handle high current without excessive heating. Wide copper traces and copper pours are commonly used to distribute current evenly across the PCB.

3. Thermal Management Design

Effective heat dissipation is critical for high current PCBs. Design techniques include:

-

Thermal vias and copper planes

-

Heat sinks and metal core integration

-

Optimized layer stack-up for heat spreading

Proper thermal management ensures long-term stability and reliability.

4. Multilayer Stack-Up Optimization

High current PCBs often utilize multilayer designs to separate power, ground, and signal layers. This approach improves current distribution, electromagnetic compatibility (EMC), and mechanical stability.

5. Low Resistance and Low Loss Materials

Selecting suitable PCB materials with high thermal conductivity and low electrical loss further enhances performance, especially in high-power and high-temperature environments.

Applications of High Current PCBs

High current PCB solutions are widely used in:

-

Power supplies and power conversion systems

-

Electric vehicles and automotive power electronics

-

Battery management systems (BMS)

-

Industrial automation and motor drives

-

Renewable energy systems, including solar and wind power

-

Charging stations and energy storage equipment

These applications demand PCBs capable of handling continuous high current while maintaining safety and reliability.

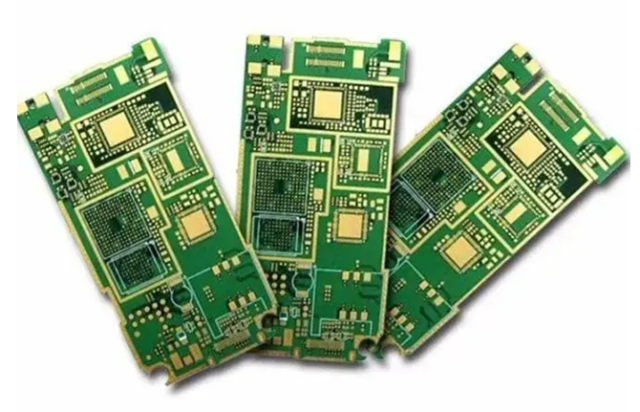

KKPCB High Current PCB Manufacturing Capabilities

KKPCB provides end-to-end high current PCB manufacturing services, including:

-

Heavy copper PCB fabrication

-

Multilayer high power PCB solutions

-

Advanced thermal management design support

-

Small batch prototyping and mass production

-

Comprehensive electrical and reliability testing

Our experienced engineering team ensures that every high current PCB meets strict electrical, thermal, and reliability standards.

Conclusion

A High Current PCB is a critical component in modern high-power electronic systems. By combining heavy copper technology, optimized trace design, and advanced thermal management, high current PCBs deliver safe, efficient, and reliable power distribution. With professional manufacturing capabilities and engineering expertise, KKPCB provides high-quality high current PCB solutions for demanding industrial, automotive, and energy applications.