ADAS PCB Layout Guidelines for Automotive Radar Systems

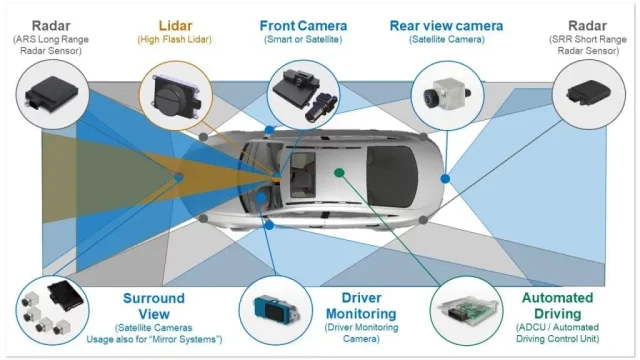

In the rapidly advancing world of automotive technology, Advanced Driver Assistance Systems (ADAS) are revolutionizing how we drive, enhancing safety and intelligence in vehicles. At the heart of many ADAS features lies the automotive radar system, which relies on precise and effective printed circuit board (PCB) design to deliver optimal performance. If you’re an engineer or designer tasked with developing ADAS radar systems, this article will provide valuable insights, actionable tips, and best practices for radar PCB design, focusing on critical elements such as antenna placement, interference minimization, and high-frequency layout techniques.

Whether you are designing a new radar module or optimizing an existing system, following these guidelines will help you achieve reliable signal integrity and superior performance in the demanding, high-frequency environment of automotive radar systems. Let’s explore the essential aspects of crafting effective PCB layouts for radar applications.

Why ADAS PCB Layout Matters for Automotive Radar Systems

Automotive radar systems are the backbone of many ADAS features, such as adaptive cruise control, blind-spot detection, and collision avoidance. These systems operate in the high-frequency range, typically between 24 GHz to 79 GHz, to accurately detect objects and obstacles. A poorly designed PCB can result in signal loss, interference, or inaccurate data, potentially jeopardizing vehicle safety.

A well-executed ADAS PCB layout ensures that radar signals are transmitted and received with minimal distortion, and it also addresses other key concerns like heat management, electromagnetic interference (EMI), and compact design requirements for modern vehicles. With careful PCB design, you can enhance the radar system’s reliability and meet stringent automotive standards.

Key Principles of Radar PCB Design for ADAS

Designing a PCB for automotive radar systems involves multiple critical factors. Below are the core principles to keep in mind when working on high-frequency PCB layouts for ADAS applications.

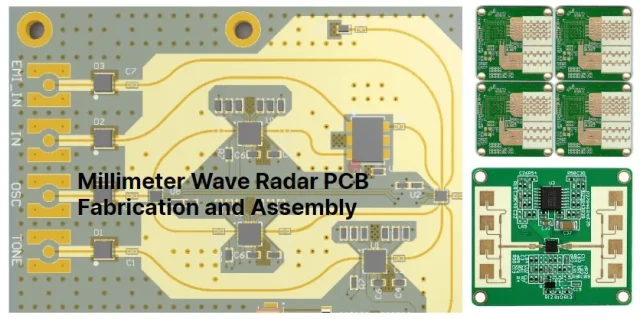

1. Material Selection for High-Frequency Performance

The choice of PCB material is crucial when designing for radar systems that operate at high frequencies. Standard FR-4 materials may not perform well above 10 GHz due to higher dielectric losses. Instead, consider specialized high-frequency laminates like Rogers RO4000 series or PTFE-based materials, which offer low dielectric constants (typically between 2.2 and 3.5) and low loss tangents (around 0.002 to 0.004), minimizing signal attenuation.

Choosing the right material ensures that radar signals in the 77-79 GHz range, commonly used for long-range automotive applications, maintain their integrity. Additionally, make sure the material has adequate thermal properties to handle the heat generated by high-frequency components.

2. Layer Stackup for Signal Integrity

A proper layer stackup is essential for ensuring signal integrity and minimizing interference in radar systems. Most radar PCBs employ a multi-layer design to keep high-frequency signals isolated from power and ground planes. A typical stackup might include:

-

Top Layer: RF components and antenna structures.

-

Inner Layer 1: Ground plane for shielding.

-

Inner Layer 2: Power distribution.

-

Bottom Layer: Additional routing or ground.

To reduce parasitic effects, keep signal traces short on the top layer. Place a continuous ground plane directly beneath the signal layer to provide a low-impedance return path, especially for frequencies above 24 GHz. This setup helps mitigate electromagnetic interference (EMI), a common issue in high-frequency designs.

Antenna Placement in Radar PCB Design

One of the most critical aspects of radar PCB design is antenna placement. Antennas in automotive radar systems are responsible for transmitting and receiving high-frequency signals. Their positioning directly impacts the system’s accuracy and reliability.

1. Positioning for Optimal Signal Coverage

Antennas should be placed at the edges of the PCB or on a dedicated antenna layer to avoid interference from other components. For patch antennas, commonly used in radar systems, orientation is key to achieving the desired field of view (FOV). For instance, a forward-looking radar may require antennas aligned at a 0-degree angle, while side-looking systems may require antennas oriented at 90 degrees.

Ensure there is adequate clearance around the antenna—at least 5 mm—to prevent signal blockage from nearby components or metal structures. The exact clearance might vary depending on the frequency and specific design requirements.

2. Isolation from Other Components

To avoid coupling effects and unwanted interference, isolate antennas from high-speed digital circuits, power supplies, and other sensitive components. Utilize ground planes or shielding vias around the antenna area to create a protective barrier against stray signals. This practice is especially important in compact designs where space is at a premium.

Minimizing Interference in Radar Systems

Interference poses a significant challenge in automotive radar systems, given the multitude of electronic systems within a vehicle. A well-thought-out ADAS PCB layout can substantially reduce noise and ensure accurate radar performance.

1. Grounding Techniques

Effective grounding is essential to minimize interference. Use a solid ground plane beneath RF traces to maintain a consistent return path for signals. Avoid splitting the ground plane, as this can create loops that act as antennas, amplifying EMI.

Stitching vias placed around the PCB edges and near high-frequency components help connect multiple ground layers, reducing ground bounce and ensuring a low-impedance path. For example, in a 77 GHz radar system, placing vias at λ/20 intervals (approximately 3.9 mm at 77 GHz) can effectively suppress unwanted resonances.

2. Trace Routing and Impedance Matching

For high-frequency designs, trace routing must be precise to maintain signal integrity. Use controlled impedance traces, typically 50 ohms, to match the impedance of RF components and antennas. Tools like microstrip or coplanar waveguide calculators can help determine the correct trace width and spacing based on PCB material and frequency.

Minimize trace length and avoid sharp corners in the signal path. Instead, use 45-degree bends or curved traces to reduce reflections and signal loss. For instance, a trace carrying a 77 GHz signal should ideally be less than 10 mm long to limit attenuation to under 0.5 dB.

Thermal Management in ADAS PCB Layout

High-frequency radar PCB systems generate substantial heat, which can degrade component performance and reduce the lifespan of the PCB if not properly managed.

- Heat Dissipation Strategies

Thermal management is crucial, especially in compact automotive radar designs. Position heat-generating components, such as power amplifiers, away from sensitive RF circuits. Use thermal vias to transfer heat from the top layer to a heat sink or the bottom layer.

Consider adding copper pours connected to ground in unused areas of the PCB to act as heat spreaders, helping to distribute heat evenly and prevent hot spots that could compromise radar accuracy.

Design Tools and Simulation for Radar PCB Layout

Modern radar PCB design heavily relies on simulation tools to predict performance before fabrication. Use electromagnetic (EM) simulation software to analyze signal integrity, antenna radiation patterns, and EMI risks. These tools allow you to fine-tune antenna placement and trace routing for optimal performance.

Perform pre-layout simulations to verify impedance matching and post-layout checks to identify potential interference sources. Even a small mismatch in high-frequency designs can lead to significant signal loss, so thorough simulation is crucial.

Compliance with Automotive Standards

Automotive radar systems must meet strict industry standards to ensure safety and reliability. Consider the requirements of organizations like the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) when designing your ADAS PCB layout.

Key standards to consider include:

-

ISO 26262 for functional safety

-

AEC-Q100 for component reliability under harsh conditions

Ensure that your design can withstand extreme temperatures (typically -40°C to 85°C), vibrations, and humidity—all common in automotive environments. Use automotive-grade components and conduct comprehensive testing to validate performance.

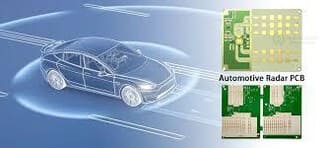

Conclusion: Building Reliable Radar Systems with ADAS PCB Layout

Designing a robust ADAS PCB layout for automotive radar systems is both a challenging and rewarding task. By focusing on material selection, antenna placement, interference minimization, and high-frequency PCB layout techniques, you can design PCBs that deliver accurate and reliable radar performance.

Leverage simulation tools, prioritize thermal management, and adhere to automotive standards to ensure your design meets safety and functionality requirements. With careful planning and attention to detail, your radar PCB can contribute to safer, smarter vehicles.

At KKPCB, we are committed to supporting your design journey with high-quality PCB manufacturing solutions tailored specifically for automotive radar systems. Let’s create the next generation of intelligent, connected vehicles together.