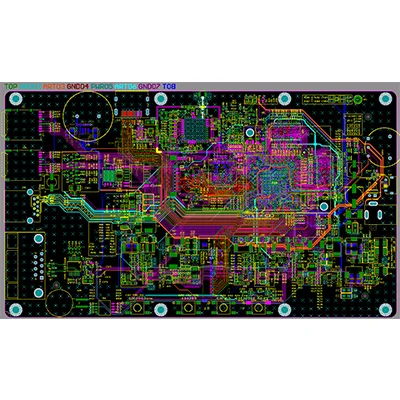

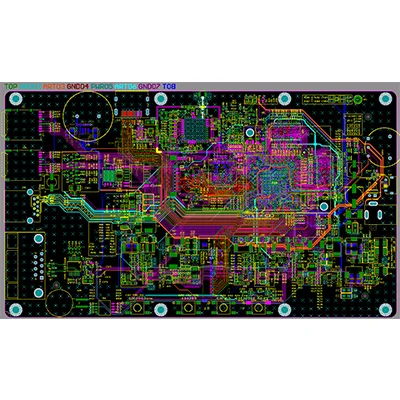

RF PCBs – Advanced Radio Frequency Printed Circuit Boards

RF (Radio Frequency) and Microwave (MW) PCBs are essential in today’s wireless technologies — from handheld medical and industrial devices to advanced radar, communication base stations, and global positioning systems.

At KKPCB, we collaborate closely with your design and engineering teams to ensure that both cost and performance targets are achieved. Our expertise allows us to recommend the most suitable materials, balance relative costs, and optimize DFM (Design for Manufacturability) for high-frequency applications.

Our RF PCB manufacturing capabilities include:

-

Typical materials: Isola FR-408, Rogers RO4350B, Taconic RF-35, etc.

-

Finished thickness: 0.8–4.0 mm

-

Surface finishes: HASL, ENIG, ENEPIG

-

Key features: solder mask plugging, controlled impedance, edge plating, hybrid stack-up, and mixed-signal integration.

When producing RF PCBs, we place great emphasis on signal integrity. We carefully control:

-

Material properties (dielectric constant Dk and loss tangent Df)

-

Low-profile copper foil selection

-

Glass weave style

-

Precise copper trace layout

Each of these factors plays a critical role in maintaining consistent performance, especially at high frequencies from 1 GHz to 77 GHz.

If you would like more information or technical guidance on our RF PCB manufacturing capability, please feel free to contact KKPCB’s technical support team. We are ready to assist with design evaluation, material selection, and cost optimization for your next high-frequency project.