What Is a Satellite PCB?

A Satellite PCB is a specialized printed circuit board designed for use in satellites and spaceborne electronic systems. These PCBs must operate reliably under extreme conditions, including vacuum, radiation, wide temperature cycles, and mechanical vibration during launch.

Compared with commercial PCBs, satellite PCBs emphasize long-term reliability, electrical stability, and strict quality control.

Key Requirements for Satellite PCB

Satellite PCBs must meet exceptionally high standards:

-

High reliability and long service life

-

Radiation resistance

-

Wide operating temperature range

-

Low outgassing materials

-

Excellent signal integrity for RF and high-speed signals

-

Mechanical strength against vibration and shock

Every design and process step is carefully controlled to avoid failure in orbit.

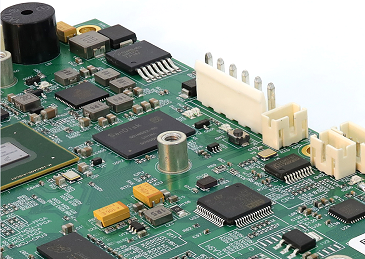

Materials Used in Satellite PCB

Material selection is critical for satellite PCB performance:

-

Low loss RF materials (RO4350B, RO4835, Taconic, Megtron 7)

-

High-Tg and low CTE laminates

-

Ceramic substrates such as Alumina PCB

-

Hybrid PCB materials for RF and power integration

-

Heavy copper layers for power distribution

These materials ensure stable electrical performance and thermal reliability in space environments.

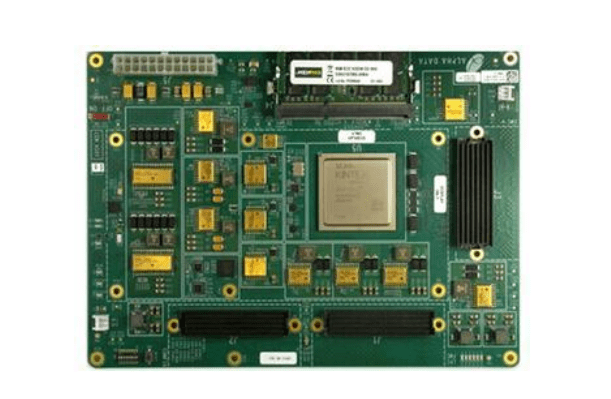

Design Considerations for Satellite PCB

Designing a satellite PCB involves multiple challenges:

-

Controlled impedance for RF and high-speed signals

-

Low insertion loss and phase stability

-

Redundant circuit paths for critical systems

-

Thermal management in vacuum conditions

-

HDI structures for compact and lightweight designs

-

Strict spacing and creepage rules

Simulation and verification are essential before fabrication.

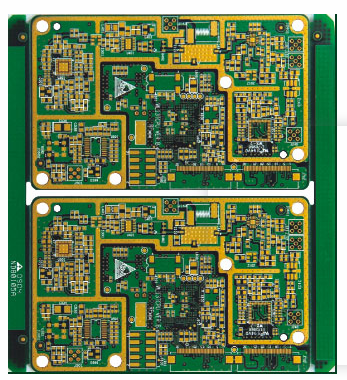

Manufacturing and Quality Control

Satellite PCB manufacturing follows aerospace-grade processes:

-

Precision multilayer lamination

-

Tight impedance and thickness control

-

Advanced via structures (blind/buried vias)

-

Strict process traceability

-

Electrical testing, thermal cycling, and reliability validation

Quality standards often align with IPC Class 3 or space-specific requirements.

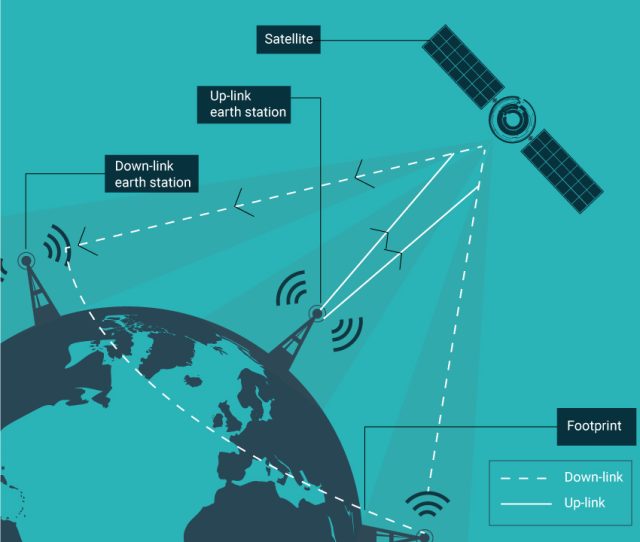

Applications of Satellite PCB

Satellite PCBs are widely used in:

-

Communication satellites

-

Earth observation satellites

-

Navigation and positioning satellites

-

Satellite RF modules and transceivers

-

Power management and control units

-

Payload and onboard processing systems

They play a critical role in mission success.

Conclusion

A Satellite PCB is a core component of modern space electronics, combining high reliability, advanced materials, and precision manufacturing. From RF signal transmission to power control, satellite PCBs must perform flawlessly over long mission lifetimes.

Partnering with an experienced satellite PCB manufacturer ensures compliance with aerospace standards and consistent performance from prototype development to small-batch production.