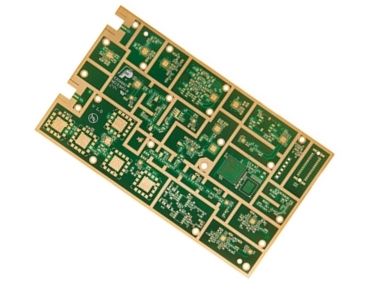

What Is RF-35 PCB?

An RF-35 PCB is a high-frequency printed circuit board fabricated using Taconic RF-35 laminate, a woven glass–reinforced hydrocarbon ceramic material designed for RF and microwave circuits. RF-35 PCB offers low dielectric loss, stable dielectric constant, and excellent dimensional stability, making it a reliable choice for high-frequency electronic designs.

Compared with standard FR-4 PCBs, RF-35 PCBs provide significantly improved signal integrity and reduced insertion loss, especially in RF test and communication systems.

Key Material Properties of RF-35 PCB

Taconic RF-35 laminate provides strong electrical and mechanical performance:

-

Dielectric constant (Dk ≈ 3.5)

Stable Dk ensures accurate impedance control. -

Low dissipation factor (Df ≈ 0.0018 @ 10 GHz)

Minimizes RF signal loss. -

Glass-reinforced structure

Enhances mechanical strength and dimensional stability. -

Low coefficient of thermal expansion (CTE)

Improves plated through-hole reliability. -

Lead-free assembly compatibility

Suitable for modern reflow processes.

These properties make RF-35 PCB suitable for demanding RF applications.

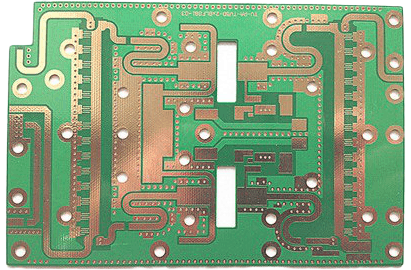

RF-35 PCB Manufacturing Considerations

Producing a RF-35 PCB requires precise control of RF-specific processes:

-

Tight impedance control for microstrip and stripline designs

-

Accurate etching to maintain RF trace geometry

-

Copper surface roughness control to reduce conductor loss

-

Controlled lamination parameters for multilayer RF-35 PCBs

-

100% electrical testing and impedance verification

Experienced PCB manufacturers ensure consistent RF-35 PCB performance.

Advantages of RF-35 PCB

RF-35 PCB offers several advantages over standard materials:

-

Lower loss than FR-4

-

Stable electrical performance over frequency

-

Excellent mechanical durability

-

Cost-effective RF laminate

-

Compatible with standard PCB fabrication processes

These benefits make RF-35 PCB widely used in RF production designs.

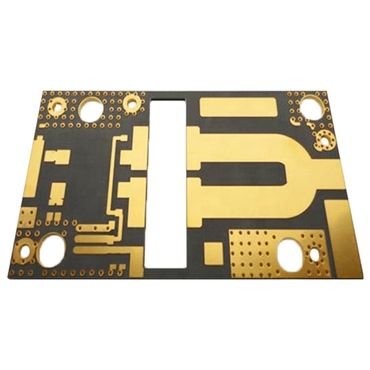

Applications of RF-35 PCB

RF-35 PCBs are commonly applied in:

-

RF Test PCB and evaluation boards

-

Wireless communication systems

-

Power amplifiers and RF front-end modules

-

Microwave filters and couplers

-

Automotive and industrial RF electronics

-

High-speed digital designs with controlled impedance

RF-35 PCB is well suited for both prototype and volume production.

RF-35 PCB vs FR-4 PCB

Compared to FR-4 PCB, RF-35 PCB delivers:

-

Lower dielectric loss

-

More stable dielectric constant

-

Better impedance control

-

Improved RF signal integrity

For RF and microwave designs, RF-35 PCB provides a clear performance advantage.

Conclusion

A RF-35 PCB is an excellent choice for RF and microwave applications requiring low loss, stable impedance, and reliable thermal performance. With its balanced electrical properties and cost efficiency, RF-35 PCB bridges the gap between standard FR-4 and high-end PTFE-based RF materials.

Selecting an experienced RF-35 PCB manufacturer ensures high-quality fabrication, accurate impedance control, and consistent RF performance.