As wireless technology continues to advance toward higher frequencies and wider bandwidth, the demand for stable and low-loss signal transmission is growing rapidly. Industries such as 5G communication, WiFi, radar sensing, satellite systems, and high-performance RF front-end modules require printed circuit boards that can maintain consistent electrical properties under challenging conditions.

A Rogers PCB is widely recognized as one of the best solutions for high frequency PCB applications. Compared to standard FR-4 materials, Rogers laminates provide lower dielectric loss, more stable dielectric constant (Dk), and better controlled impedance performance, making them ideal for RF PCB and microwave PCB designs.

This article explains what Rogers PCB is, why it is preferred for high-frequency applications, and what key factors matter in Rogers PCB manufacturing.

What Is a Rogers PCB?

A Rogers PCB is a printed circuit board manufactured using Rogers high-frequency laminate materials, designed specifically for RF and microwave signal transmission. Rogers Corporation offers a range of materials optimized for different frequency ranges, performance requirements, and cost targets.

Rogers PCB materials are widely used because they offer:

-

Stable dielectric constant (Dk) for controlled impedance

-

Low dissipation factor (Df) for reduced insertion loss

-

Excellent high-frequency signal integrity

-

Reliable performance across temperature variations

-

Suitability for RF transmission lines, antennas, and microwave circuits

In many RF and high frequency signal applications, Rogers PCB is the preferred choice for achieving predictable and repeatable electrical performance.

Why Choose Rogers PCB for High Frequency Applications?

1. Low Loss for Improved Signal Transmission

High frequency signals are sensitive to dielectric loss. When signals travel through PCB traces, energy is absorbed by the dielectric material and converted into heat. This creates insertion loss and reduces signal strength.

Rogers PCB materials are engineered for low loss performance, which helps improve:

-

RF signal efficiency

-

Link budget performance in wireless systems

-

Receiver sensitivity

-

Overall system reliability

For applications such as 5G and microwave communication, lower loss can directly improve system coverage and stability.

2. Stable Dk for Controlled Impedance Routing

In RF PCB and microwave PCB design, controlled impedance is essential. Impedance mismatch leads to reflections, return loss issues, and performance degradation.

Rogers PCB provides stable Dk characteristics, enabling:

-

Accurate impedance control (50Ω / 75Ω typical)

-

Consistent microstrip and stripline performance

-

Reliable phase and timing stability

This makes Rogers PCB highly suitable for precision RF trace routing.

3. Better High Frequency Signal Integrity

High frequency signal integrity depends on many factors including material properties, stack-up design, trace geometry, and manufacturing consistency.

Rogers PCB improves high frequency signal integrity by:

-

Reducing dielectric loss and signal attenuation

-

Supporting clean transmission line behavior

-

Minimizing performance variation across production batches

For high-frequency designs, this stability is critical for predictable results.

Common Rogers PCB Materials and Applications

Different Rogers materials are selected based on frequency range, loss requirements, and design complexity.

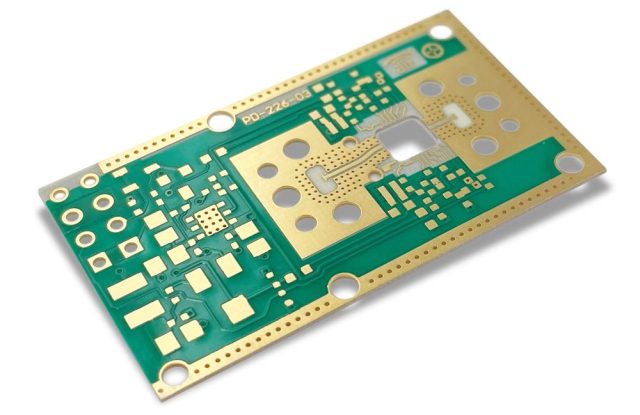

RO4003C PCB

RO4003C PCB is a popular Rogers material option that balances performance and cost. It is widely used for:

-

RF front-end circuits

-

Antenna feed networks

-

Wireless communication modules

-

High frequency signal routing

RO4003C is often chosen when controlled impedance and stable RF performance are required.

RO3003 PCB

RO3003 PCB is designed for ultra-low loss and high-frequency stability. It is commonly used in:

-

Microwave circuits

-

Radar systems

-

Satellite communication modules

-

High precision RF applications

RO3003 PCB is ideal for applications requiring low insertion loss and stable dielectric properties at higher frequencies.

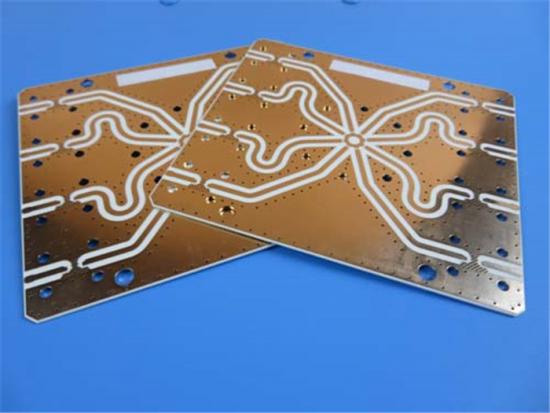

RT/duroid PCB

RT/duroid PCB materials are PTFE-based laminates offering extremely low loss and excellent performance in microwave and mmWave applications.

They are commonly used in:

-

High-end antennas

-

Microwave amplifiers and filters

-

Aerospace and defense RF systems

-

mmWave communication modules

RT/duroid materials are typically selected for the most demanding RF designs.

Rogers PCB vs FR-4 PCB: What’s the Difference?

FR-4 is widely used in general electronics, but it may not perform well at high frequencies due to higher loss and unstable electrical properties.

Rogers PCB advantages over FR-4 include:

-

Lower Df for reduced signal attenuation

-

More stable Dk for impedance accuracy

-

Better high-frequency consistency

-

Improved performance for RF and microwave routing

If your design involves GHz-level signals, Rogers PCB can significantly improve performance compared to standard FR-4.

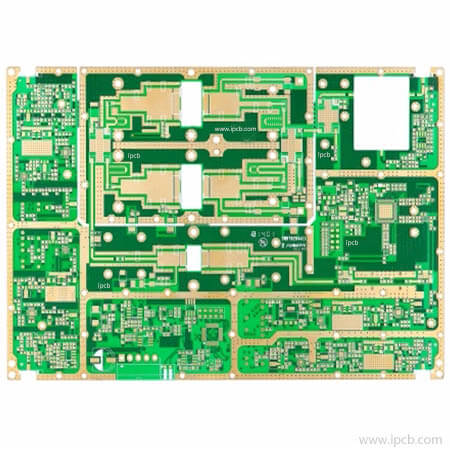

Rogers PCB Manufacturing and Fabrication Challenges

Rogers PCB manufacturing requires more advanced process control than standard PCB fabrication. To ensure stable RF performance, manufacturers must carefully manage:

1. Stack-Up and Lamination Control

Accurate stack-up thickness is critical for controlled impedance PCB production. Proper lamination ensures consistent dielectric spacing and reliable performance.

2. Trace Geometry and Etching Precision

RF traces require tight tolerance control. Small variations in line width can cause impedance deviation, affecting return loss and insertion loss.

3. Drilling and Via Reliability

Via transitions can introduce discontinuities in RF routing. High-quality drilling and plating are essential for reliable Rogers PCB performance.

4. Surface Finish Selection

Surface finish impacts both solderability and high-frequency loss performance. The correct finish choice helps maintain stable RF signal transmission.

5. Hybrid Rogers PCB Stack-Up Capability

Many products use a hybrid Rogers PCB, combining Rogers laminates with FR-4 layers to balance performance and cost. This requires experienced process handling to ensure strong bonding and consistent reliability.

Best Practices for Rogers PCB Design

To maximize the performance of a Rogers PCB, designers should consider:

-

Controlled impedance routing with proper stack-up planning

-

Keeping RF traces short and minimizing discontinuities

-

Avoiding sharp corners and using smooth routing bends

-

Maintaining continuous reference planes under RF traces

-

Adding ground via stitching for EMI control

-

Optimizing RF connector launch design

-

Using simulation and impedance calculation tools when necessary

These practices help ensure stable high-frequency signal performance and improved RF efficiency.

Applications of Rogers PCBs

Rogers PCBs are widely used in high-frequency and RF industries, including:

-

5G base stations and small cells

-

WiFi and wireless communication modules

-

Radar and automotive sensing systems

-

Satellite communication equipment

-

GPS and positioning devices

-

Microwave filters, couplers, and power dividers

-

Antenna systems and RF front-end modules

-

Aerospace and defense RF electronics

Rogers PCB is an ideal solution wherever stable high-frequency performance is required.

Conclusion: Rogers PCB for Reliable High Frequency Performance

A Rogers PCB is a proven high-performance solution for RF and microwave electronics requiring controlled impedance, low insertion loss, and stable high-frequency signal integrity. With material options such as RO4003C PCB, RO3003 PCB, and RT/duroid PCB, Rogers laminates support a wide range of high-frequency applications including 5G, radar, satellite, and advanced wireless communication systems.

If you need a reliable partner for Rogers PCB fabrication, controlled impedance testing, and high-reliability production, KKPCB can support your project from engineering review to mass production.