A Thermal Management PCB is a specialized printed circuit board engineered to effectively manage heat generation in electronic systems. As devices such as automotive ECUs, 5G modules, RF circuits, power electronics, and industrial IoT devices operate at higher power densities, efficient heat dissipation becomes critical to maintain performance, reliability, and lifespan.

Key Features of Thermal Management PCBs

1. Metal Core and High Thermal Conductivity Materials

Thermal management PCBs often use aluminum or copper cores and high thermal conductivity substrates to rapidly transfer heat away from critical components, preventing hotspots and thermal stress.

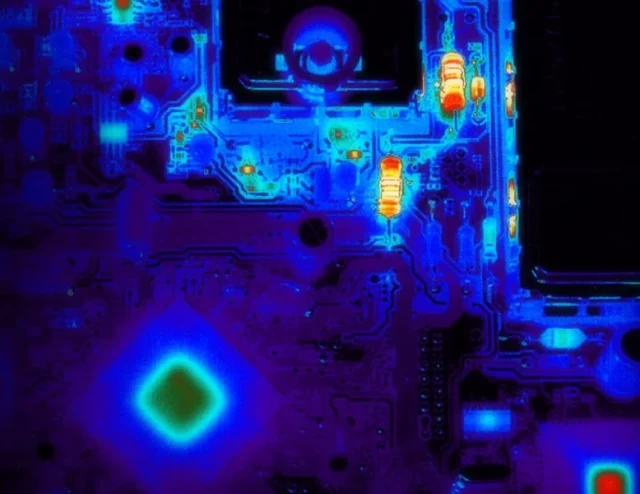

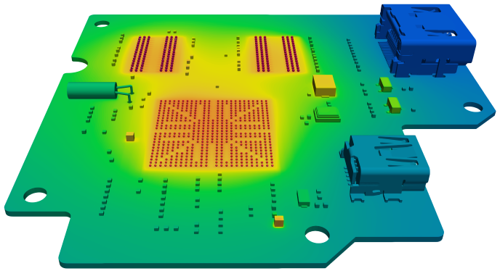

2. Thermal Vias and Heat Paths

Incorporating thermal vias, copper planes, and heat spreaders allows heat to be distributed across layers and dissipated effectively, improving component stability and PCB longevity.

3. Multilayer and HDI Designs

Multilayer thermal PCBs combine signal, power, and ground layers with thermal layers, enabling efficient routing, EMI control, and high-speed performance while managing heat.

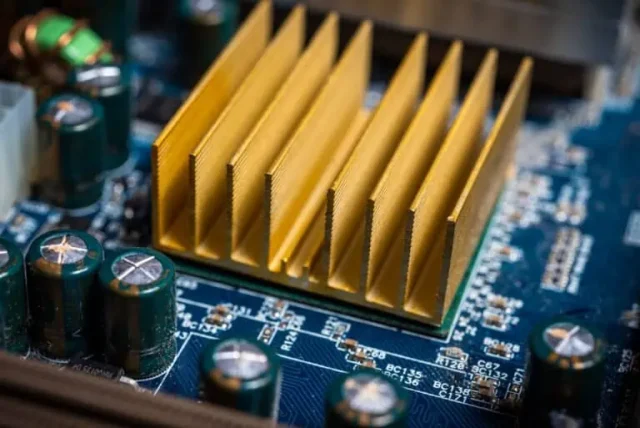

4. Surface Mount Heat Sinks and Cooling Integration

Thermal management PCBs are compatible with SMD heat sinks, cold plates, and forced-air or liquid cooling systems, ensuring optimal thermal performance for high-power devices.

5. Controlled Impedance and Signal Integrity

Even with thermal considerations, these PCBs maintain precise impedance control and signal integrity, crucial for RF, 5G, and high-speed digital circuits.

Applications of Thermal Management PCBs

Thermal management PCBs are critical in applications where heat dissipation and reliability are essential:

-

Automotive power modules, ADAS, and radar systems

-

5G mmWave and RF front-end modules

-

High-power computing and networking equipment

-

IoT devices and wearable electronics

-

Industrial automation and power electronics

-

Semiconductor testing and ATE boards

Manufacturing Considerations

Producing high-quality thermal management PCBs requires advanced materials and precise fabrication techniques:

-

Metal core selection and lamination for optimal heat transfer

-

Placement of thermal vias and copper planes

-

Controlled layer thickness and alignment in multilayer designs

-

Surface treatments and finishes for enhanced thermal conductivity

-

Thermal simulations, AOI, X-ray, and electrical testing for reliability

These considerations ensure consistent performance, effective heat dissipation, and long-term PCB reliability.

Conclusion

Thermal Management PCBs are essential for modern high-power, high-density electronics, providing efficient heat dissipation, superior signal integrity, and long-term reliability. From automotive and 5G RF modules to industrial IoT and power electronics, thermal management PCB technology ensures optimized performance and extended lifespan for demanding applications.