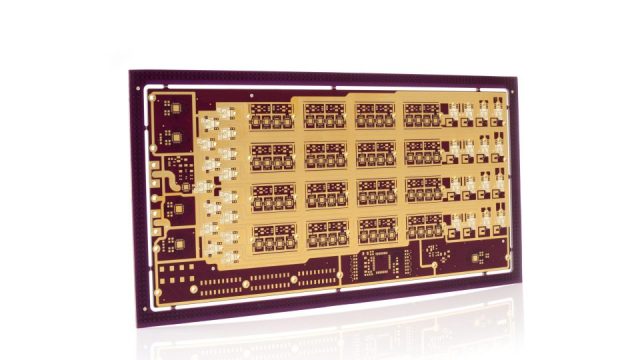

A Fine Pitch PCB is a printed circuit board designed to support high-density integrated circuits with extremely small pad spacing, such as BGA, QFN, CSP, and flip-chip packages. As modern electronics continue to shrink in size while increasing functionality, fine pitch PCB technology becomes essential for achieving high routing density, reliable assembly, and superior electrical performance.

Key Features of Fine Pitch PCBs

1. Ultra-Fine Line and Space

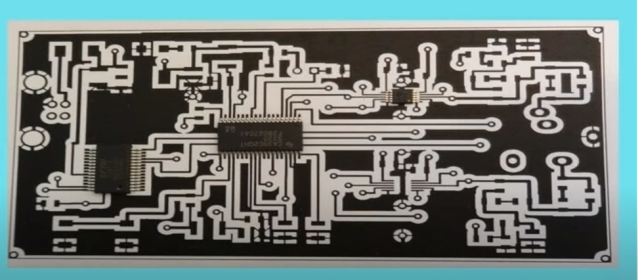

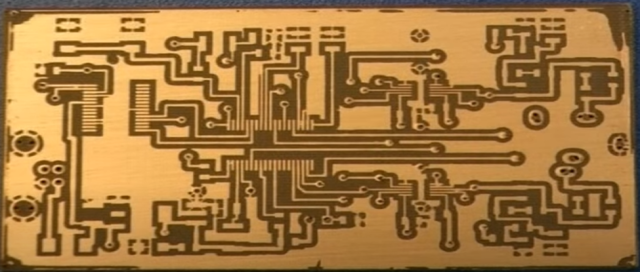

Fine pitch PCBs allow trace widths and spacing as low as 3 mils or smaller, enabling dense routing for complex ICs without increasing board size.

2. Microvia and Via-in-Pad Technology

Microvias and via-in-pad designs reduce signal path lengths and parasitic inductance, improving signal integrity and high-frequency performance, especially for RF and high-speed digital circuits.

3. Multilayer Stackups

Advanced multilayer stackups accommodate power, ground, and signal layers, providing controlled impedance, EMI suppression, and reliable power distribution.

4. High Pin Count Support

Fine pitch PCBs are optimized for high pin count BGAs, QFNs, and CSP ICs, enabling compact yet high-performance electronic modules.

5. Thermal and Mechanical Reliability

Using high-quality laminates and precise fabrication, fine pitch PCBs maintain mechanical integrity and thermal stability, crucial for automotive, aerospace, and industrial applications.

Applications of Fine Pitch PCBs

Fine pitch PCBs are widely used in applications requiring miniaturization, high-speed performance, and high-density IC integration:

-

High pin count semiconductor IC test boards

-

IoT and wearable devices

-

RF, microwave, and 5G communication modules

-

Automotive ECUs and ADAS modules

-

Medical and industrial compact electronics

-

High-speed computing and networking equipment

These applications benefit from the precision routing, signal integrity, and compact layout that fine pitch PCBs provide.

Manufacturing Considerations for Fine Pitch PCBs

Producing reliable fine pitch PCBs requires advanced PCB manufacturing processes:

-

High-precision laser drilling and microvia formation

-

Tight line/space and layer registration control

-

Via filling and plating for via-in-pad structures

-

Sequential lamination for multilayer stackups

-

AOI, X-ray inspection, and electrical testing to ensure high yield

Experienced PCB manufacturers ensure consistent electrical performance, high reliability, and repeatable assembly quality.

Conclusion

Fine Pitch PCBs are a cornerstone for modern high-density electronics, enabling engineers to integrate more functionality into smaller footprints without sacrificing signal integrity or reliability. From high pin count ICs to RF and high-speed applications, fine pitch PCB technology ensures precise assembly, superior electrical performance, and long-term durability.