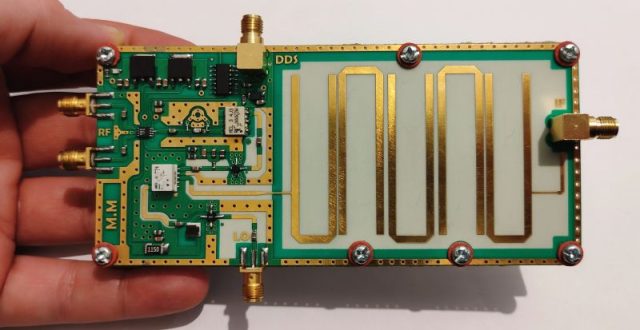

A Microwave IC Test PCB is a highly specialized semiconductor test board designed for validating microwave and millimeter-wave (mmWave) integrated circuits in Automated Test Equipment (ATE) environments. These test PCBs are essential for accurately measuring critical microwave parameters such as gain, insertion loss, phase accuracy, linearity, noise figure, and frequency stability.

With the rapid expansion of 5G mmWave, automotive radar, satellite communication, aerospace, and high-frequency sensing applications, microwave ICs now operate at extremely high frequencies. This places stringent requirements on microwave IC test PCB design, material selection, and manufacturing precision.

Key Design Requirements of Microwave IC Test PCBs

1. Ultra-Precise Controlled Impedance

Microwave IC test PCBs require extremely tight impedance control to prevent signal reflection and phase distortion. Transmission lines must be accurately modeled and manufactured to maintain consistent RF performance.

2. Ultra-Low-Loss High-Frequency Materials

To minimize signal attenuation at microwave and mmWave frequencies, low-Dk and ultra-low-Df laminates such as PTFE, Rogers, or hybrid high-frequency materials are commonly used.

3. RF Grounding and Via Fencing

Optimized grounding structures, dense via fencing, and RF shielding techniques reduce EMI, suppress parasitic effects, and improve signal isolation at high frequencies.

4. Precision Connector and Interface Design

Microwave IC test PCBs often integrate high-frequency connectors, coax launches, and probe interfaces. Accurate connector transitions are critical to reduce insertion loss and impedance discontinuities.

5. Thermal and Mechanical Stability

Microwave testing may involve long test cycles and power-intensive operation. Stable materials, reliable stackups, and robust mechanical design ensure consistent performance throughout testing.

Applications of Microwave IC Test PCBs

Microwave IC test PCBs are widely used in testing:

-

5G mmWave RF front-end ICs

-

Automotive radar and ADAS microwave devices

-

Satellite and aerospace microwave ICs

-

High-frequency communication and sensing chips

-

Advanced analog and mixed-signal microwave ICs

These applications demand extreme accuracy, repeatability, and low signal loss.

Manufacturing Capabilities for Microwave IC Test PCBs

Producing reliable microwave IC test PCBs requires advanced manufacturing expertise, including:

-

Ultra-tight controlled impedance fabrication

-

Low-loss and PTFE-based material processing

-

HDI and multilayer high-frequency PCB manufacturing

-

Precision drilling and RF connector assembly

-

Prototype, small batch, and volume production support

Advanced manufacturing ensures stable microwave performance across different test platforms.

Why Microwave IC Test PCB Quality Is Critical

At microwave and mmWave frequencies, even minor PCB defects can cause significant signal loss, phase errors, and measurement instability. High-quality microwave IC test PCBs deliver:

-

Accurate high-frequency and mmWave measurements

-

Reduced insertion loss and parasitic effects

-

Improved test repeatability and reliability

-

Higher ATE efficiency and reduced test risk

Conclusion

The Microwave IC Test PCB is a cornerstone of high-frequency semiconductor testing, enabling precise validation of microwave and mmWave ICs. Through ultra-low-loss materials, controlled impedance routing, optimized RF grounding, and precision manufacturing, these test boards ensure accurate and repeatable microwave test results.

Partnering with an experienced microwave IC test PCB manufacturer helps accelerate product validation, improve RF accuracy, and support advanced high-frequency semiconductor applications.