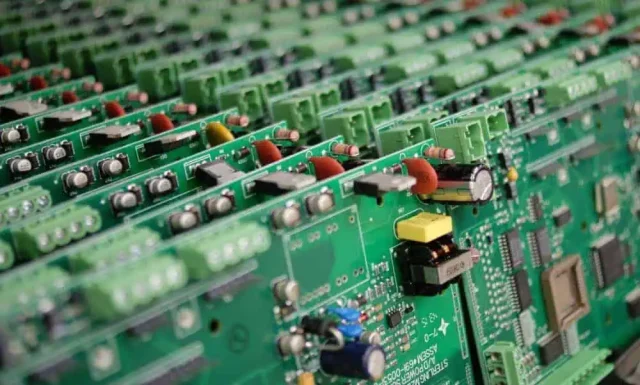

In today’s highly competitive electronics market, speed and reliability are critical during the product development stage. High-reliability small batch PCB manufacturing enables engineers to accelerate product validation, shorten engineering iteration cycles, and reduce development risk before mass production.

This article explains how small batch PCB manufacturing supports rapid prototyping, design verification, and engineering optimization, helping companies bring high-quality products to market faster.

Why Small Batch PCB Manufacturing Matters in Product Development

During early-stage development, engineers often need multiple design iterations to validate functionality, performance, and manufacturability. Small batch PCB manufacturing allows teams to:

- Quickly verify circuit performance and signal integrity

- Identify design issues before large-scale investment

- Test different materials, stack-ups, or layouts

- Reduce overall development cost and time to market

Compared with mass production, small batch PCB manufacturing offers flexibility and speed, making it ideal for engineering validation.

High Reliability: A Key Requirement for Engineering Validation

For product validation, PCB reliability is just as important as speed. High-reliability PCB manufacturing ensures that test results accurately reflect real-world performance.

Key reliability factors include:

- Stable PCB materials with consistent dielectric properties

- Precise impedance control for high-speed and RF designs

- Tight tolerance control on trace width and dielectric thickness

- Strict process control during lamination and fabrication

High-reliability small batch PCBs provide engineers with confidence that test results are meaningful and repeatable.

Supporting Faster Engineering Iteration

Engineering iteration depends on fast feedback loops. Small batch PCB manufacturing shortens these cycles by:

- Offering quick-turn PCB fabrication

- Supporting frequent design changes

- Enabling rapid validation of layout updates

- Reducing waiting time between design revisions

With reliable small batch PCB production, engineers can focus on optimizing performance instead of troubleshooting manufacturing inconsistencies.

Applications of Small Batch High-Reliability PCBs

High-reliability small batch PCB manufacturing is widely used in:

- High-speed digital systems

- RF and high-frequency circuits

- Automotive electronics development

- Medical device prototyping

- Industrial and aerospace electronics

In these applications, accuracy and consistency during validation are essential.

Transition from Small Batch to Mass Production

A major advantage of working with an experienced PCB manufacturer is the smooth transition from small batch PCB manufacturing to mass production.

By using production-grade materials, processes, and quality standards during small batch fabrication, design validation results can be directly transferred to large-scale manufacturing, reducing risk and rework.

Conclusion

High-reliability small batch PCB manufacturing plays a vital role in accelerating product validation and engineering iteration. By combining fast turnaround with consistent quality, small batch PCBs enable engineers to validate designs quickly, optimize performance efficiently, and prepare confidently for mass production.

Partnering with a reliable PCB manufacturer ensures that every engineering iteration moves your product closer to market success.