Heavy Copper PCBs: High-Current Solutions for Power Electronics

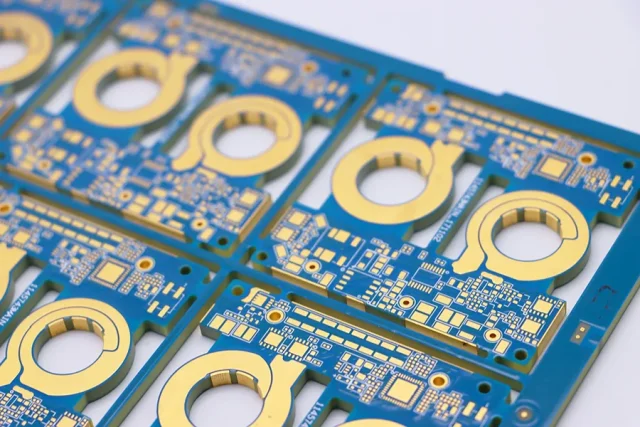

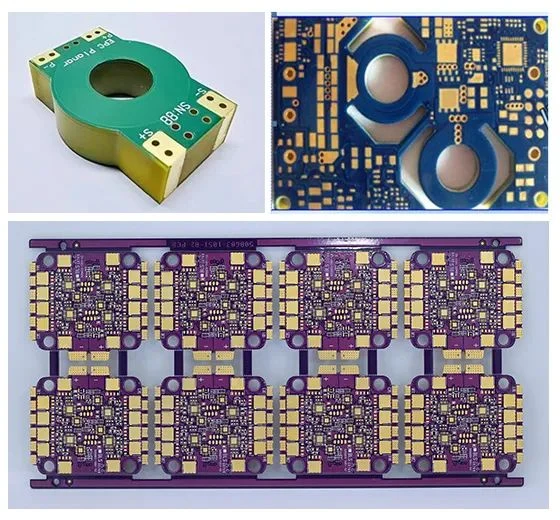

As electronic systems evolve toward higher power density, stronger reliability requirements, and increasingly harsh operating environments, Heavy Copper PCBs have become indispensable across power electronics, automotive systems, industrial control, and energy infrastructure. Unlike standard PCBs—typically manufactured with 1oz–3oz copper—a Heavy Copper PCB is defined as any PCB using ≥3oz copper on one or more layers, including both outer and inner layers.

At KKPCB, we specialize in producing high-reliability heavy copper boards for power-critical applications, leveraging advanced etching, plating, and thermal management techniques to support high current, high voltage, and extreme environmental conditions.

What Is a Heavy Copper PCB?

A Heavy Copper PCB uses significantly thicker copper foil to support:

-

Higher current-carrying capacity

-

Improved heat spreading and dissipation

-

Enhanced mechanical strength

-

Increased reliability in harsh environments

For applications where standard trace width alone cannot support the required amperage, designers rely on thicker copper to reduce resistance, maintain stable temperature rise, and ensure long-term durability.

Heavy copper designs are common in:

-

High-power industrial modules

-

High-current power supplies

-

Energy infrastructure

Why Heavy Copper PCBs Are Used

As current requirements increase, simply widening the trace is not enough. Wider traces consume board area and complicate routing. Therefore, increasing copper thickness becomes the only effective solution to safely carry high current.

Heavy Copper PCBs are chosen when a system requires:

-

High current (tens to hundreds of amps)

-

High voltage isolation

-

Harsh environment operation

-

Long-term thermal stability

-

Mechanical reinforcement at connector interfaces

These characteristics make them ideal for modern power electronics that require both compact size and extreme reliability.

Advantages of Heavy Copper PCBs

Heavy Copper PCBs provide several performance and reliability benefits:

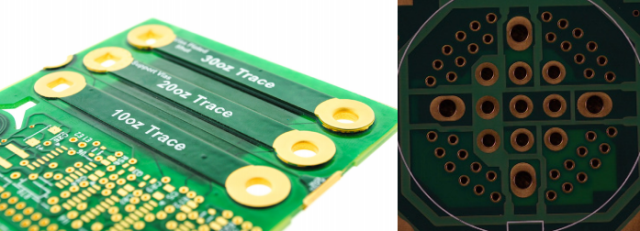

1. Increased Current-Carrying Capability

Thicker copper significantly lowers resistance, enabling the PCB to safely handle higher amperage. Combined with optimized trace width, designers can achieve stable high-current performance without excessive heat buildup.

2. Superior Thermal Performance

Heavy copper improves thermal conductivity across the entire PCB. This allows:

-

Better heat spreading

-

Lower localized hotspots

-

Greater resistance to thermal cycling

-

Improved reliability under high-power loads

This is essential for power converters, IGBT modules, and motor drivers.

3. Enhanced Mechanical Strength

Thicker copper strengthens:

-

Plated-through holes

-

Pads and connectors

-

High-stress regions

This increases durability, especially in environments exposed to vibration, shock, or high insertion forces.

4. Reliable Heat Dissipation

Heavy Copper PCBs dissipate heat efficiently, preventing overheating in systems with:

-

High-power regulation

-

Large current switching

-

Repetitive thermal cycles

Their enhanced dissipation factor protects sensitive components from thermal fatigue.

5. Excellent Conductivity and Integration

The low resistance and high conductivity of heavy copper make it ideal for connecting multiple power stages within a system, maintaining stable energy distribution and minimizing power loss.

KKPCB Heavy Copper Capabilities

With years of specialized experience, KKPCB supports heavy copper PCB manufacturing with precision engineering and strict process control. Our capabilities include:

Copper Weight

-

Outer layers: up to 15oz

-

Inner layers: up to 12oz

Minimum Trace & Spacing

-

4oz → 13mil/13mil

-

5oz → 18mil/18mil

-

6oz → 18mil/18mil

-

12oz → 20mil/32mil

Drilling & Board Specs

-

Minimum hole size: 10mil

-

Board thickness: 0.6–6mm

Surface Finishes

-

ENIG

-

Hard Gold

-

Immersion Silver

-

Lead-free HASL

-

OSP

-

ENEPIG

Solder Mask Colors

Green, Blue, Black, White, Red, Yellow, Matte Black, Matte Green, Purple

Via Options

Tenting, plugging, or non-covered vias

Testing

-

AOI

-

Fly-probe testing

Lead Time

-

Fabrication: 5–10 days

-

Assembly: 2–3 days

Our engineering team supports DFM reviews, current simulation, thermal analysis, and stack-up optimization to ensure stable performance in demanding power applications.

Applications of Heavy Copper PCBs

Heavy Copper PCBs are widely used across industries that demand high reliability and power performance:

Military Electronics

-

Radar systems

-

Communication modules

-

Weapon control units

Automotive Systems

-

EV power modules

-

Battery management systems

-

Rail signal transmission

Power Distribution Equipment

-

Grid switching systems

-

High-power rectifiers

-

Overload protection relays

Transportation & Railway

-

Traction converters

-

Power converters

-

Line monitoring units

Industrial Automation

-

Welding systems

-

High-current safety relays

-

Surge protection devices

Renewable Energy

-

Energy storage systems

-

Hydroelectric control panels

These industries rely on heavy copper to ensure product longevity, heat stability, and safe electrical performance even in extreme environments.

Conclusion

Heavy Copper PCBs play a critical role in modern power electronics. Their ability to handle high current, dissipate heat, and withstand mechanical stress makes them essential for high-performance systems across military, automotive, industrial, and renewable energy sectors.

At KKPCB, we deliver heavy copper PCBs with high precision, stable quality, and fast lead time—supported by a professional engineering team dedicated to ensuring your power systems remain efficient, reliable, and ready for the future.

If you need high-current PCB solutions, thermal optimization support, or custom copper stack-up engineering, KKPCB is ready to assist.