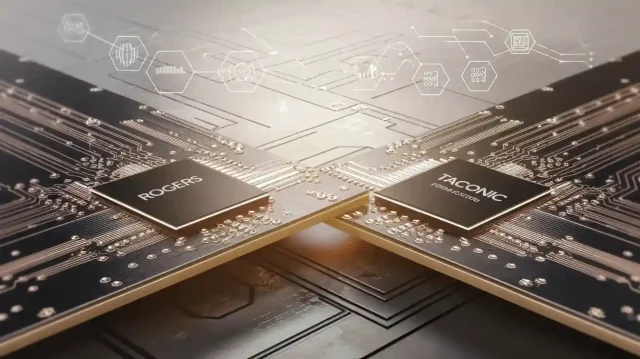

Millimeter-wave (mmWave) systems operate at extremely high frequencies where dielectric stability, insertion loss, and impedance accuracy directly affect system performance. Selecting the right PCB material is critical. Taconic RF-35 PCB for mmWave applications is widely used in high-frequency RF designs due to its low loss characteristics, excellent mechanical stability, and manufacturing reliability.

Taconic RF-35 provides a balanced solution for mmWave systems requiring both performance and cost efficiency.

What Is Taconic RF-35 PCB?

Taconic RF-35 PCB is based on a ceramic-filled PTFE composite laminate engineered for RF, microwave, and mmWave applications. It offers stable electrical properties across a wide frequency range.

Key material properties include:

-

Dielectric constant (Dk) ≈ 3.5

-

Low dissipation factor (Df ≈ 0.0018 @ 10 GHz)

-

Excellent thermal and mechanical stability

-

Low moisture absorption

These properties make Taconic RF-35 PCB for mmWave suitable for demanding RF environments.

Why Choose Taconic RF-35 PCB for mmWave Applications?

Low Dielectric Loss at mmWave Frequencies

Taconic RF-35 minimizes signal attenuation, enabling cleaner signal transmission at mmWave bands.

Stable Dielectric Constant

Consistent Dk ensures reliable impedance control and predictable RF performance across operating conditions.

Manufacturing-Friendly PTFE Composite

Compared with pure PTFE materials, RF-35 offers improved dimensional stability and easier processing.

Cost-Performance Balance

Taconic RF-35 provides strong RF performance at a more competitive cost than ultra-low-Dk PTFE options.

Controlled Impedance Design with Taconic RF-35 PCB

Accurate impedance control is essential for mmWave circuits. Manufacturing Taconic RF-35 PCB for mmWave requires:

-

Stackup simulation and impedance calculation

-

Precise dielectric thickness control

-

Fine-line etching and copper profile optimization

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance verification

These steps ensure minimal reflection and optimal signal integrity.

Typical Taconic RF-35 PCB Stackups for mmWave

Common Taconic RF-35 PCB stackup options include:

-

2-layer RF signal and ground plane designs

-

Multilayer mmWave PCBs with dedicated RF layers

-

Hybrid stackups combining RF-35 with FR-4 or other RF materials

Hybrid stackups help balance performance, cost, and mechanical requirements.

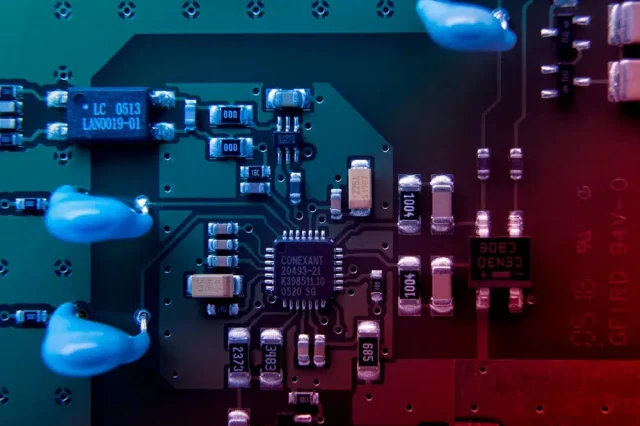

Manufacturing Considerations for Taconic RF-35 mmWave PCBs

A professional mmWave PCB manufacturer must control:

-

Fine line width and spacing for high-frequency traces

-

Copper surface roughness to reduce conductor loss

-

Drilling and via plating for PTFE-based materials

-

Lamination pressure and temperature stability

These factors directly affect mmWave signal quality.

Applications of Taconic RF-35 PCB in mmWave Systems

Taconic RF-35 PCB for mmWave is widely used in:

-

5G mmWave communication modules

-

mmWave antennas and RF front-end modules

-

Automotive radar systems

-

High-frequency wireless backhaul

-

IoT and industrial sensing applications

These applications demand low loss and high reliability.

Choosing a Manufacturer for Taconic RF-35 PCB for mmWave

When selecting a supplier for Taconic RF-35 PCB for mmWave, consider:

-

Experience with Taconic RF materials

-

mmWave PCB fabrication and testing capability

-

Controlled impedance manufacturing expertise

-

Prototype-to-mass-production scalability

An experienced manufacturer ensures stable performance and production consistency.

Conclusion

Taconic RF-35 PCB for mmWave applications offers an excellent balance of low loss, stable dielectric properties, and manufacturability. With precise impedance control and RF-focused fabrication processes, Taconic RF-35 PCBs support reliable mmWave system performance across a wide range of applications.

Partnering with a professional high-frequency PCB manufacturer ensures your Taconic RF-35 mmWave designs meet both performance and production requirements.