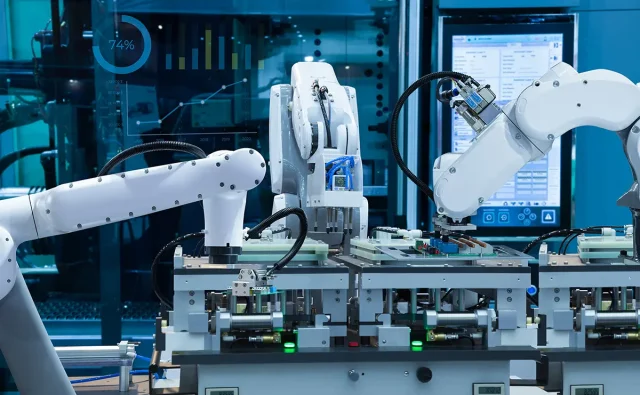

Smart manufacturing pushes electronics into an environment where precision, robustness, and real-time responsiveness are mandatory. At the center of this ecosystem lies the Smart Factory PCB, the hardware foundation that drives IIoT sensor nodes, PLC control modules, autonomous robots, edge-computing gateways, and high-speed industrial communication networks. A Smart Factory PCB must deliver electrical reliability, long-term material stability, and consistent performance in the presence of vibration, EMI, temperature stress, and high-density data exchange.

A well-engineered Smart Factory PCB is not merely a carrier of components—it becomes the backbone of industrial intelligence.

1. Material Engineering for Harsh Industrial Environments

Smart Factory PCB materials require significantly higher reliability than consumer-grade electronics. High-TG FR-4, halogen-free laminates, and reinforced glass epoxy systems are typically chosen to handle:

• Thermal cycling from 0°C to 120+°C

• High-humidity exposure

• Chemical and particulate contamination

• Vibrational stress from motion platforms and robotic actuators

A Smart Factory PCB must maintain dielectric stability, controlled impedance, and mechanical strength under these conditions. Designers often move toward advanced resin systems with low moisture absorption and robust copper adhesion, ensuring decades of operational stability.

2. High-Density Layout for Intelligent Automation Systems

Automation platforms like industrial robots and real-time PLC modules rely on Smart Factory PCB high-density layouts to integrate sensors, microcontrollers, power stages, and communication modules within compact footprints.

Key engineering considerations include:

• Controlled differential pairs for industrial Ethernet, EtherCAT, PROFINET, and TSN

• Short, low-inductance paths for power stages driving motors and solenoids

• Dense multi-layer stackups supporting simultaneous low-noise analog and high-speed digital zones

• Rigid-flex Smart Factory PCB structures enabling integration into robotic joints and compact housings

The challenge is achieving signal integrity, clean power distribution, and EMI control without inflating PCB size or manufacturing cost.

3. Real-Time Communication and Signal Integrity

Smart Factory PCB systems often operate at microsecond-level latencies. Any signal degradation can compromise control loops, safety systems, and automation precision.

Therefore, Smart Factory PCB engineering emphasizes:

• Differential pair symmetry for deterministic Ethernet timing

• Ground reference stitching to prevent common-mode interference

• Segregation of analog, digital, and power domains

• Return-path engineering to prevent ground bounce and EMI radiation

Signal integrity is not optional—it is a foundational requirement for industrial intelligence.

4. Power Delivery and High-Current Management

Industrial PCBs must support motor drivers, actuators, valves, servo systems, and high-power edge processors. Smart Factory PCB power design must handle:

• Large copper pours for multi-amp currents

• Thermal dissipation through heat spreading planes

• Power integrity analysis for noise-sensitive digital loads

• Vias-in-pad and heavy-copper routes for rugged current flow

The objective is predictable electrical behavior even during rapid load switching, ensuring stable automation performance.

5. Integration of IIoT Connectivity and Edge Computing

Next-generation Smart Factory PCB platforms integrate:

• Wi-Fi 6, 5G, or private industrial cellular

• BLE, UWB, and Zigbee mesh networking

• Embedded AI accelerators for predictive maintenance

• Edge processors for real-time data filtering

A Smart Factory PCB must be engineered for high-frequency routing, controlled impedance traces, and shielded RF zones, allowing robust industrial communication under constant EMI exposure.

6. Reliability Testing and Lifecycle Assurance

Because industrial systems often run 24/7 for many years, Smart Factory PCB validation includes:

• HALT/HASS accelerated aging

• Temperature-humidity-bias testing

• Vibration and shock qualification

• Solder joint fatigue analysis

• IPC-6012 Class 3 manufacturing standards

Long-term reliability determines whether automation lines stay online or experience costly downtime.

Conclusion

The Smart Factory PCB is the structural and electrical foundation of Industry 4.0—enabling autonomous robots, precision control loops, high-speed industrial networking, and intelligent IIoT ecosystems. Through advanced materials, high-density stackup engineering, robust power distribution, EMI-conscious routing, and mission-critical reliability testing, the Smart Factory PCB transforms static hardware into adaptive, resilient, and data-driven machinery.

As manufacturing becomes more interconnected and more autonomous, the sophistication of Smart Factory PCB design will directly define the performance, efficiency, and intelligence of next-generation industrial systems.