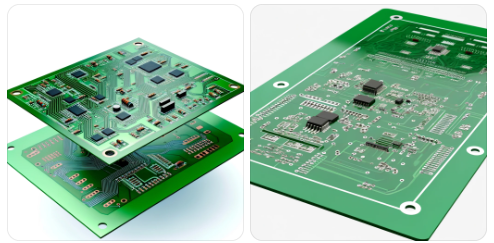

Modern industrial robots, collaborative robots (cobots), AGVs, AMRs, and aerial autonomous platforms rely heavily on Robotics PCBs for motion control, sensor fusion, decision-making, communication, and continuous power delivery. As robots transition toward higher precision and autonomy, the electronic design inside them becomes increasingly complex.

A well-engineered Robotics PCB determines performance in terms of stability, latency, environmental durability, and real-time responsiveness.

This article highlights the primary engineering principles that create reliable, high-performance Robotics PCBs suitable for industrial and autonomous applications.

1. Key Functional Requirements of Robotics PCBs

A. Motion Control & Real-Time Processing

Robotics motion controllers rely on deterministic timing. PCBs supporting servo drives, motor control, and encoder feedback must ensure:

-

controlled impedance for high-speed feedback signals

-

minimized latency between sensors and MCU/FPGA

-

robust isolation between power and logic domains

B. Power Distribution Architecture

Robots include high-current actuators, servo motors, and switching power converters.

A stable Power Integrity (PI) strategy must include:

-

low-inductance power layers

-

optimized copper weighting

-

noise-isolated power domains for digital/analog subsystems

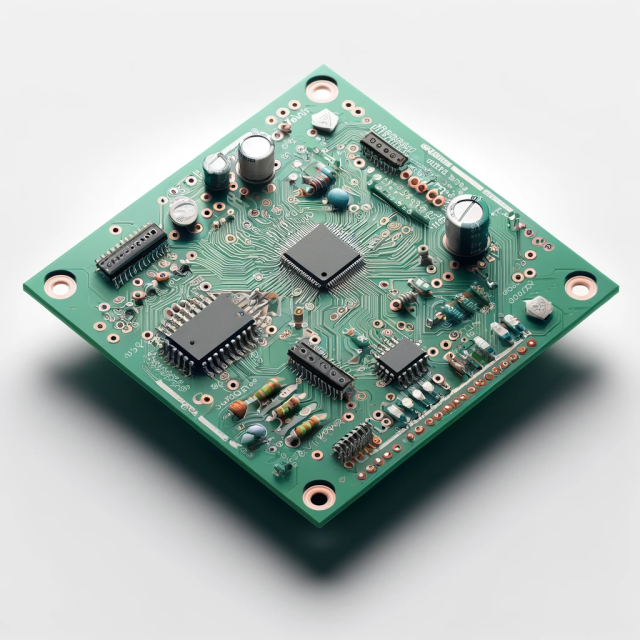

C. High-Density Sensor Integration

Robots integrate LiDAR, IMUs, force sensors, joint encoders, vision modules, ToF sensors, and environmental monitors.

This demands HDI Robotics PCB structures with:

-

microvias and blind/buried vias

-

fine-pitch BGA breakout

-

multi-layer routing for sensor fusion

2. Material Engineering for Robotics PCBs

The choice of material determines signal speed, reliability, and thermal performance.

High-Tg FR-4 Laminates

Suitable for general control electronics and industrial communication.

Low-Loss Laminates (Rogers, Megtron, Taconic)

Required when Robotics PCBs must support:

-

robot vision modules

-

advanced navigation computers

-

high-speed sensor buses

Copper Foil Selection (RA / ED)

RA copper enhances vibration resistance for moving robotic joints.

3. Signal Integrity (SI) and High-Speed Routing Strategies

Industrial robots use advanced communication protocols such as:

-

EtherCAT

-

CAN-FD

-

SPI/QSPI

-

MIPI CSI/DSI

-

LVDS differential signaling

To maintain signal integrity, Robotics PCBs require:

-

impedance-controlled traces

-

differential pair routing

-

length matching

-

stitching vias and return-path engineering

Clean signals ensure precise motor control, low-latency vision processing, and stable feedback loops.

4. Power Integrity (PI) Optimization for Robotics

The motion system produces current surges that can destabilize the entire PCB if not engineered properly.

Core PI techniques include:

-

multilayer power-gnd pairs

-

wide copper pours on motor-driver rails

-

decoupling networks optimized for switching frequency

-

isolation of noisy motor power from microcontroller domains

A stable PI architecture directly improves robotic system responsiveness and accuracy.

5. EMI/EMC Engineering for Robotic Environments

Robots operate near high-power motors, metal frames, switching regulators, and multiple RF sources. Robotics PCBs must:

-

use ground-coupled signal layers

-

implement shielded stackup structures

-

isolate power converters

-

place via fences around sensitive areas

-

filter external and internal noise sources

EMI/EMC stability is essential for reliable autonomous operation.

6. Mechanical and Environmental Reliability

Robotics PCBs are exposed to harsh conditions:

-

constant vibration in robotic joints

-

rapid temperature cycling

-

dust, humidity, and industrial noise

-

long operational hours (24/7 factories)

Reliability reinforcement methods include:

-

high-Tg laminates

-

thicker copper for power paths

-

reinforced solder joints

-

conformal coating where necessary

KKPCB also validates robotic PCBs through:

-

IPC-6012 Class 3 testing

-

thermal cycle qualification

-

vibration and shock testing

-

humidity and endurance stress tests

7. Engineering Summary

A Robotics PCB is more than just a circuit board—it is the foundation of robotic intelligence, motion, perception, and system safety.

Through optimized materials, controlled SI/PI design, EMI/EMC engineering, and environmental durability strategies, engineers can significantly enhance robotic performance and reliability.

KKPCB provides end-to-end engineering support for Robotics PCB design, prototyping, stackup planning, and mass production, ensuring industrial and autonomous systems achieve long-term, high-reliability operation.