With the rapid deployment of 5G networks, antenna performance has become a critical factor in achieving high data rates, low latency, and stable wireless communication. Selecting the right PCB material is essential, and RO4003 PCB for 5G antenna applications has become a popular choice due to its excellent high-frequency performance, stable dielectric properties, and cost-effective manufacturing characteristics.

This article explores why RO4003 material is well-suited for 5G antenna designs and what to consider during manufacturing.

What Is RO4003 PCB Material?

RO4003C is a high-frequency laminate developed by Rogers Corporation, specifically designed for RF and microwave applications. It offers performance characteristics close to PTFE materials while maintaining easier fabrication similar to standard FR-4.

Key properties of RO4003 PCB material include:

-

Dielectric constant (Dk) ≈ 3.38 (stable across frequency)

-

Low dissipation factor (Df ≈ 0.0027)

-

Excellent thermal and mechanical stability

-

Compatibility with standard PCB manufacturing processes

These properties make RO4003 an ideal material for 5G antenna PCB applications.

Why RO4003 PCB Is Ideal for 5G Antenna Design

5G antenna systems operate at high frequencies where signal loss and impedance variation must be minimized. RO4003 PCB for 5G antenna designs offers several advantages:

-

Stable Impedance Control: Tight Dk tolerance ensures consistent antenna impedance

-

Low Signal Loss: Low Df improves radiation efficiency and gain

-

High Frequency Capability: Suitable for sub-6 GHz and many microwave applications

-

Manufacturing Reliability: Easier processing compared to PTFE-based PCBs

These benefits help antenna designers achieve predictable RF performance and higher production yield.

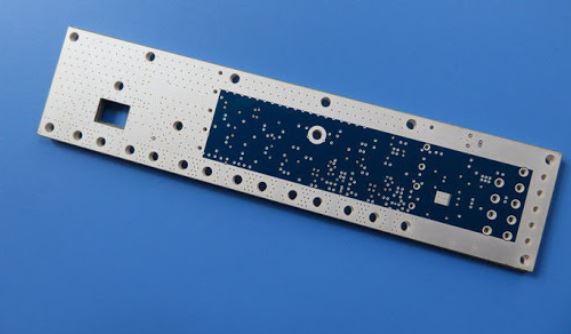

Impedance Control and Stack-up Considerations

Accurate impedance control is essential for 5G antenna PCB performance.

When manufacturing RO4003 PCBs:

-

Trace width and dielectric thickness must be precisely controlled

-

Copper thickness and surface finish affect RF loss

-

Hybrid stackups may be used to combine RO4003 layers with FR-4 for control or power layers

Proper stack-up design ensures stable impedance and optimal antenna matching.

Manufacturing Considerations for RO4003 PCBs

Producing RO4003 PCBs for 5G antennas requires experience in high-frequency PCB manufacturing, including:

-

Controlled lamination and etching processes

-

Tight tolerance management

-

RF-specific testing such as TDR impedance measurement

-

Consistent quality control from prototype to mass production

An experienced PCB manufacturer ensures the electrical performance of RO4003 material is fully realized.

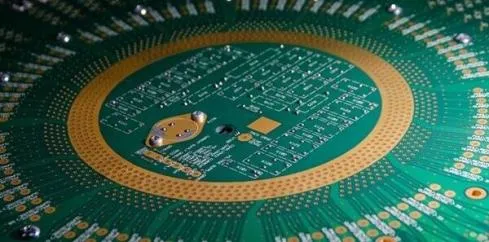

Applications of RO4003 PCB in 5G Systems

RO4003 PCB material is widely used in:

-

5G base station antennas

-

Small cell and microcell antennas

-

RF front-end modules

-

Wireless communication and IoT devices

-

Microwave and RF transmission circuits

These applications benefit from RO4003’s balance of performance, reliability, and cost.

Conclusion

RO4003 PCB for 5G antenna applications offers an excellent balance between high-frequency performance and manufacturability. With low loss, stable dielectric properties, and compatibility with standard PCB processes, RO4003 is a proven material choice for modern 5G antenna designs.

By working with an experienced high-frequency PCB manufacturer, engineers can ensure precise impedance control, consistent quality, and reliable RF performance for 5G antenna applications.