Advanced microwave modules demand transmission structures that deliver extremely low loss, high linearity and wideband frequency stability. Modern radar front-ends, satellite communication units and mmWave transceivers rely heavily on Duroid 5880 PCB technology because it offers exceptionally low dielectric loss, high-frequency predictability and precise impedance behavior. When engineered into microstrip and coplanar waveguide (CPW) structures, Duroid 5880 PCB materials significantly reduce conductor loss and preserve high-frequency linearity across 1–67 GHz microwave systems.

This article explores why Duroid 5880 PCB microstrip and coplanar structures are now foundational in next-generation microwave modules and how they elevate RF performance, signal purity and thermal stability.

1. High-Frequency Advantages of Duroid 5880 PCB in Microwave Microstrip and Coplanar Designs

Duroid 5880 PCB is a PTFE-glass microfiber composite designed specifically for microwave and RF systems requiring ultra-low loss and consistent RF properties. Its electrical characteristics—Dk ≈ 2.20 ± 0.02 and Df ≈ 0.0009 at 10 GHz—make it one of the most stable materials for microstrip and coplanar waveguide structures.

These material characteristics provide:

• Extremely low dielectric loss for long microwave interconnects

• Stable Dk for phase-coherent microstrip routing

• Smooth copper interfaces minimizing conductor loss

• Accurate impedance control in CPW and microstrip RF paths

• Wideband frequency linearity ideal for microwave modules

Because microwave modules often include multi-octave routing and precision transmit/receive chains, the Duroid 5880 PCB substrate becomes essential for minimizing distortion and attenuation.

2. Conductor Loss Reduction with Duroid 5880 PCB Microstrip/CPW Routing

At microwave and mmWave frequencies, conductor loss is magnified by skin-effect concentration and copper surface roughness. Duroid 5880 PCB reduces conductor loss through:

Low-profile rolled copper

Smooth copper lowers surface resistance and reduces high-frequency scattering, dramatically improving microstrip and CPW efficiency.

Low-Dk dielectric reducing field confinement

A Dk of 2.20 spreads the EM field more uniformly, decreasing copper interaction and reducing microstrip conductor attenuation.

Precision dielectric thickness control

Stable substrate thickness ensures consistent current distribution and predictable microstrip/CPW impedance.

Using Duroid 5880 PCB microstrip and CPW routing can reduce conductor losses by 20–40% compared to standard PTFE and more than 60% compared to FR-4 in high-frequency microwave modules.

3. Preserving High-Frequency Linearity in Advanced Microwave Modules

High-frequency linearity is critical for systems such as X-band radar, Ku-band links, Ka-band satellite modules and mmWave transceivers. Duroid 5880 PCB enables superior linearity through:

Ultra-stable dielectric constant

Phase drift and group delay variations are minimized, ensuring coherent microwave signal paths.

Low-dispersion transmission behavior

Microstrip and CPW structures on Duroid 5880 maintain uniform propagation velocity across wideband frequencies.

Minimal intermodulation distortion

Low-loss PTFE reduces dielectric heating, preventing nonlinear distortion in high-power microwave modules.

Stable impedance in multi-layer stackups

Duroid 5880 PCB maintains consistent impedance for transitions between microstrip, CPW and via-fed microwave structures.

This translates into stronger signal integrity, flatter gain response and cleaner output spectra in microwave modules requiring precision phase and amplitude control.

4. Microstrip vs CPW on Duroid 5880 PCB for Microwave Modules

Both Duroid 5880 PCB microstrip and Duroid 5880 PCB coplanar waveguide structures are widely used, but each has unique engineering benefits.

Microstrip on Duroid 5880 PCB

• Lowest conductor loss for long microwave paths

• Ideal for antenna feed networks

• Excellent for broadband distribution lines

• Highly reproducible and stable in multilayer RF layouts

Coplanar Waveguide (GCPW) on Duroid 5880 PCB

• Superior mode suppression and EMI immunity

• Better impedance stability under manufacturing variation

• Strong performance at mmWave frequencies (24–77 GHz)

• Ideal for sensitive microwave transceiver front-ends

In both structures, the combination of ultra-low-loss PTFE and smooth copper surfaces ensures minimal energy dissipation and exceptional transmission linearity.

5. Key Microwave Applications Benefiting from Duroid 5880 PCB Microstrip/CPW

Modern microwave modules heavily rely on Duroid 5880 PCB because it supports demanding RF environments and wideband operation. The most common applications include:

• 5G/6G microwave and mmWave modules

• Satellite communication uplink/downlink chains

• X-band, Ku-band and Ka-band radar assemblies

• Microwave measurement instruments

• High-frequency power amplifiers and LNAs

• Phased-array beamforming networks

• High-linearity LO distribution and mixers

• Ultra-wideband microwave receivers

In all these applications, Duroid 5880 PCB improves signal integrity, enhances power handling, reduces conductor loss and preserves phase coherence.

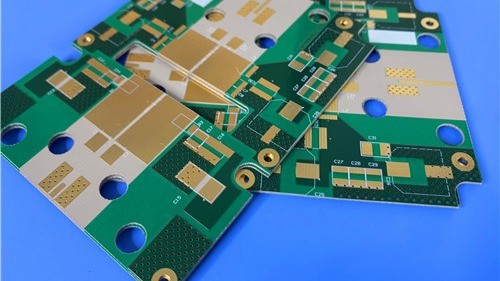

6. KKPCB Expertise in Duroid 5880 PCB Microstrip and Coplanar Fabrication

KKPCB has extensive engineering capability in manufacturing Duroid 5880 PCB for microwave modules, including:

• Ultra-precise dielectric thickness control

• Low-profile rolled copper for reduced conductor loss

• Tight impedance tolerance (±5% or better) for microstrip/CPW

• Laser microvias for RF transitions

• Multi-material hybrid stackups (5880 + RO3003/RO4003C/ceramics)

• Full RF testing: TDR, S-parameters, line loss, impedance validation

This ensures each Duroid 5880 PCB delivers optimal performance across microwave and mmWave frequency bands.