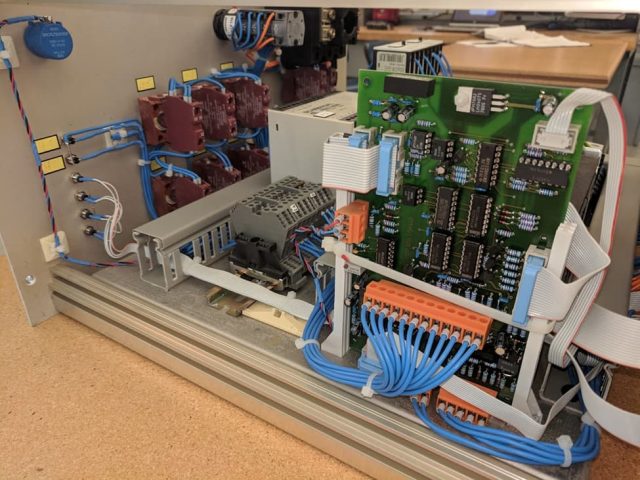

PCBs for Industrial Automation: The Backbone of Modern Control Systems

In the fast-evolving world of industrial automation, Printed Circuit Boards (PCBs) are the unsung heroes that power the technology behind every automated machine, robot, and control system. From factory floors to advanced robotics, choosing the right PCB is crucial to the success of your automation project. At KKPCB, we specialize in offering tailored PCB solutions that meet the exacting demands of industrial automation, ensuring the reliability, durability, and efficiency of your systems.

Industrial automation demands precision, strength, and flexibility—qualities that are embodied in two standout PCB technologies: Rigid-Flex PCBs and Heavy Copper PCBs. These two solutions not only offer high performance in extreme conditions but also support complex designs that fit seamlessly into tight spaces, while delivering optimal power management and signal integrity.

Why PCBs Are Essential for Industrial Automation and Control

Industrial control systems rely heavily on the performance and reliability of their PCBs. From controlling high-tech machinery on the factory floor to managing sensors in extreme environments, PCBs serve as the central nervous system of automated processes. However, designing these PCBs comes with unique challenges, particularly in harsh industrial conditions. Components need to withstand:

-

Extreme Temperatures: From freezing cold to intense heat, industrial systems operate in temperatures ranging from -40°C to 85°C. The PCB must maintain functionality without cracking or degrading.

-

Vibration and Shock: Continuous machinery vibrations can loosen components or damage traces. Strong, durable PCB construction is critical.

-

High Power Requirements: Many industrial systems require high current, generating considerable heat. Effective heat dissipation is essential to avoid overheating.

-

Signal Integrity: Precise operations depend on clear, uninterrupted signals. Impedance mismatches or noise can disrupt processes, making controlled impedance a necessity for high-speed control systems.

This is where Rigid-Flex PCBs and Heavy Copper PCBs offer their powerful solutions.

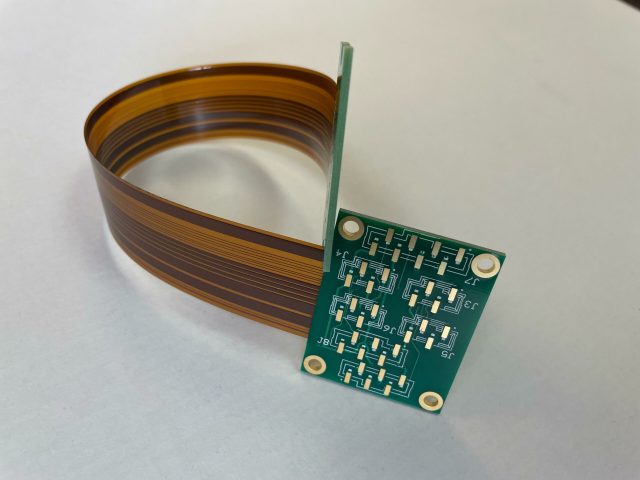

Rigid-Flex PCBs: Combining Strength and Flexibility for Industrial Automation

Rigid-Flex PCBs combine the robustness of rigid boards with the flexibility of flexible circuits, making them ideal for compact, high-performance applications. Whether in robotics, control panels, or sensor modules, Rigid-Flex PCBs deliver:

-

Space Efficiency: These boards can bend and fold, fitting seamlessly into tight spaces without compromising functionality—critical for compact control systems or robotics.

-

Lightweight Design: Rigid-Flex boards reduce the need for additional connectors, cables, and components, resulting in a lighter, more streamlined system.

-

Enhanced Reliability: With fewer connection points, the risk of failure due to loose connectors or damaged wires is significantly reduced, especially in high-vibration environments.

-

Durability in Harsh Environments: Designed with materials that resist temperature fluctuations and chemical exposure, Rigid-Flex PCBs are perfect for harsh factory environments.

Applications:

-

Robotic Arms: Rigid-Flex PCBs are ideal for systems that require constant movement while maintaining signal integrity.

-

Control Panels: The compact, flexible nature of these boards allows for intricate designs in space-constrained environments.

-

Sensor Modules: Sensors in industrial settings often require flexible connections to adapt to unique mounting positions.

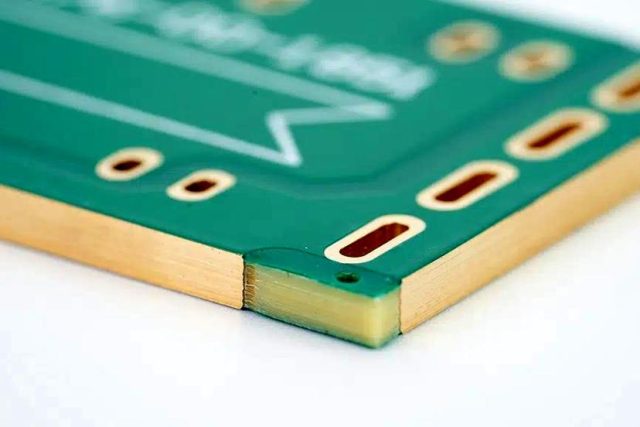

Heavy Copper PCBs: Powering High-Current Industrial Systems

Heavy Copper PCBs are built to handle high current and dissipate heat effectively, making them indispensable in industrial systems that demand powerful and reliable performance. With copper layers ranging from 3 oz/ft² to 20 oz/ft², these PCBs offer:

-

High Current Capacity: Heavy Copper PCBs can handle current up to 100 amps or more, perfect for power-hungry machinery without risk of overheating.

-

Superior Heat Dissipation: The added copper thickness naturally draws heat away from critical components, extending the board’s lifespan and reliability.

-

Mechanical Strength: The thicker copper provides durability against physical stress and thermal cycling, making them ideal for demanding industrial environments.

-

Long-Term Reliability: These boards are designed for longevity, minimizing failures due to trace damage.

Applications:

-

Power Supply Units: Heavy Copper PCBs ensure stable and efficient power delivery to industrial equipment.

-

Motor Controllers: They manage the high current required to drive large motors in automated production lines.

-

Energy Management Systems: These boards are essential for ensuring uninterrupted power flow in systems that monitor and control energy use in industrial facilities.

How to Choose the Right PCB for Your Industrial Automation Project

Selecting the right PCB solution depends on various factors. Here’s how to make an informed decision:

-

Assess Environmental Conditions:

Will your PCB operate in extreme temperatures or high-vibration environments? Rigid-Flex PCBs are ideal for dynamic settings, while Heavy Copper PCBs excel in high-power, heat-dissipating applications. -

Consider Power Requirements:

If your system needs to handle currents over 10 amps, Heavy Copper PCBs are your best option due to their superior current capacity and heat management. -

Space Constraints:

For compact systems, Rigid-Flex PCBs provide flexibility and space-saving designs. -

Signal Integrity:

Ensure your board design supports the required impedance levels, especially for high-speed applications where clean, precise signals are vital. -

Longevity:

For industrial systems that run 24/7, choose PCBs made from durable materials that will reduce maintenance and replacement costs.

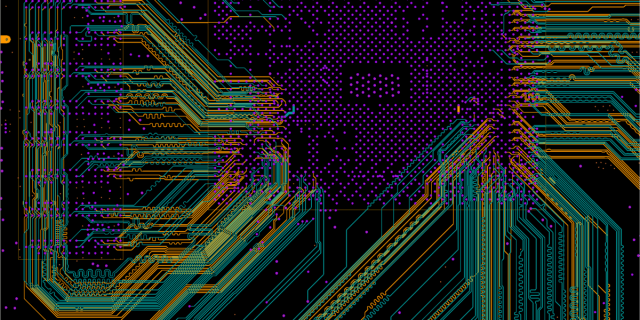

Design Tips for Industrial Automation PCBs

To enhance your PCB’s performance and longevity, consider these tips:

-

Use High-Quality Materials: Choose materials like FR-4 or Polyimide to withstand temperature extremes and exposure to chemicals.

-

Optimize Trace Widths: For high-current applications, wider traces reduce resistance and prevent heat buildup.

-

Incorporate Thermal Vias: Help dissipate heat in Heavy Copper designs and prevent potential hotspots.

-

Minimize Connection Points: Fewer connectors in Rigid-Flex designs lower the risk of failure under vibration.

-

Test for Signal Integrity: Use simulation tools to ensure impedance values are accurate, especially for high-speed systems.

Future Trends in PCBs for Industrial Automation and Control

The landscape of industrial automation is evolving, and so is PCB technology. Key trends to watch include:

-

Integration of IoT: As factories adopt smart technologies, PCBs must support IoT connectivity with embedded sensors and wireless modules.

-

Miniaturization: Demand for smaller, more efficient designs is driving the need for compact Rigid-Flex PCBs.

-

Higher Power Densities: As systems become more powerful, Heavy Copper PCBs will play an increasingly important role in managing heat and power demands.

-

Sustainability: The shift toward eco-friendly materials and processes will reduce the environmental impact of PCB production.

Conclusion: Powering Industrial Automation with the Right PCBs

PCBs are the core components that power industrial automation systems, driving performance, efficiency, and reliability in some of the world’s toughest environments. Whether you need the flexibility and durability of Rigid-Flex PCBs or the power-handling capabilities of Heavy Copper PCBs, choosing the right solution will ensure your automation project thrives. At KKPCB, we specialize in crafting custom PCB solutions that meet the highest standards of quality, ensuring your systems run smoothly, efficiently, and reliably.

Let us be your partner in innovation—together, we can power the future of industrial automation with PCBs that fuel success.