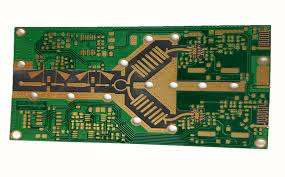

Modern wireless systems—from 5G radio units and phased-array antenna modules to automotive radar and satellite communication terminals—demand PCBs that deliver high RF power handling, exceptional phase stability, and ultra-low loss. As antenna modules continue to shrink while operating at higher frequencies, selecting the correct laminate becomes a mission-critical design decision.

Among all mid-frequency RF substrates, Rogers RO4350B™ stands out as the most balanced, production-friendly laminate that combines low dielectric loss, stable dielectric constant (Dk), high thermal reliability, and excellent manufacturability. This makes RO4350B an ideal material for high-frequency antenna PCBs, RF front-end modules, phased-array beamformers, and microwave subsystems.

Below, we explore how RO4350B maximizes RF performance and how KKPCB’s high-frequency PCB expertise ensures consistent, low-loss, high-density RF designs for next-generation antenna systems.

1. Why RO4350B Matters: The Foundation of High-Frequency Antenna Performance

In RF engineering, substrate material defines:

-

Insertion loss along RF transmission lines

-

Phase stability across temperature cycles

-

Antenna gain, efficiency, and beam accuracy

-

Power handling for PA (Power Amplifier) and high-current RF networks

-

Impedance control for microstrip/stripline/CPW structures

-

System reliability under high thermal stress

At frequencies from 1 GHz to 40+ GHz, even small shifts in Dk or copper roughness cause:

-

Phase delay errors

-

Beam-steering distortion

-

Increased VSWR

-

Reduced radiation efficiency

This is why RF designers increasingly depend on RO4350B PCB laminates—engineered to deliver consistent high-frequency performance where FR-4 cannot.

2. RF Performance Advantages of RO4350B

(1) High RF Power Handling

RO4350B withstands elevated RF power with:

-

Higher thermal conductivity

-

Low dielectric heating

-

Superior electrical strength

This results in:

-

Higher PA efficiency

-

Stable antenna radiation performance

-

Reduced thermal drift in high-power RF chains

Keyword density: RF power handling / high-power RF / thermal stability / antenna power performance.

(2) Ultra-Stable Dielectric Constant (Dk ≈ 3.48)

RO4350B’s consistent Dk ensures:

-

Precise impedance control

-

Minimal phase distortion

-

Repeatable antenna resonance

-

Accurate phased-array beamforming

Keyword density: Dk stability / dielectric constant / phase stability / RF impedance.

(3) Low Loss Tangent (Df ≈ 0.0037 @10 GHz)

Low-loss RO4350B reduces:

-

Transmission line loss

-

Feed network attenuation

-

RF front-end insertion loss

Ideal for:

-

5G FR1 & FR2 (mmWave)

-

GNSS/L-band

-

Radar 24/77 GHz

-

High-efficiency IoT antennas

Keyword density: low-loss PCB / insertion loss / RF antenna efficiency / microwave PCB.

(4) Excellent Thermal Reliability vs FR-4

FR-4 suffers from:

-

High loss tangent

-

Dielectric drift

-

Poor thermal stability

RO4350B offers:

-

High Tg

-

Low thermal expansion

-

Long-term environmental stability

This makes it suitable for harsh environments:

-

Base-stations

-

Aerospace

-

Automotive radar

-

Outdoor CPE

(5) HDI-Ready & High-Density RF Routing

RO4350B supports:

-

Fine-line etching

-

Laser microvias

-

Stacked/buried vias

-

Low-roughness copper

-

High-density RF feed networks

Essential for compact high-frequency antenna modules and beamforming IC integration.

Keyword density: HDI RF PCB / high-density routing / microstrip / CPW / RF module miniaturization.

3. RO4350B vs FR-4 for RF Antenna Applications

| Characteristic | RO4350B | FR-4 |

|---|---|---|

| Df @10 GHz | Ultra-low (~0.0037) | Very high (~0.02) |

| Phase stability | Excellent | Poor |

| Impedance accuracy | ±5% | Inconsistent |

| Thermal reliability | High | Low |

| RF frequency capability | 1–40 GHz | <2 GHz |

| Signal loss | Minimal | Severe |

Summary:

FR-4 cannot maintain stable RF behavior at high frequencies.

RO4350B is the correct choice for low-loss, high-frequency antenna PCBs.

4. Applications Where RO4350B PCB Laminates Excel

-

5G RRU/AAU, small cell, macro cell radio boards

-

Phased-array radar & AESA beamforming modules

-

Automotive 24/77 GHz radar systems

-

Satellite terminals (Ku/Ka bands)

-

High-efficiency IoT & LPWAN antennas

-

Microwave filters, couplers, LNAs, PAs

-

GNSS / GPS antenna front-ends

Every application benefits from low-loss performance, high power handling, and stable phase response.

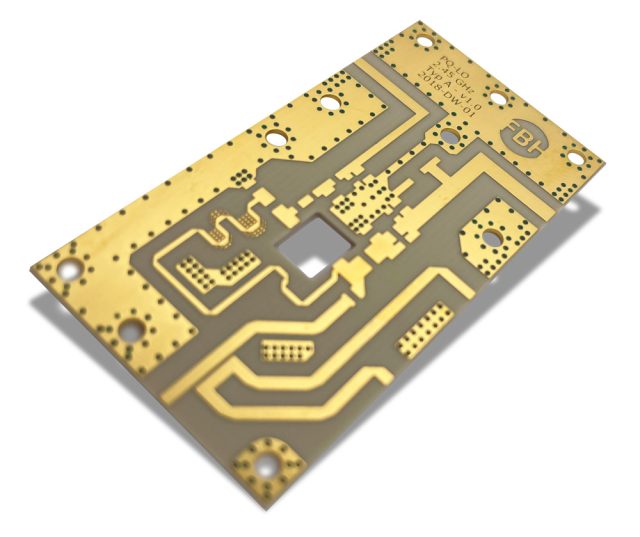

5. KKPCB’s High-Frequency Manufacturing Capabilities

KKPCB provides advanced manufacturing optimized for RO4350B RF PCBs and hybrid RF stackups, including:

• Impedance Control ±5% for RF Structures

Precise microstrip, stripline, and grounded CPW implementation.

• Advanced Hybrid Stackups (RO4350B + FR-4)

Cost-optimized without compromising RF performance.

• High-Density Interconnect (HDI) RF PCB Manufacturing

Laser microvias, stacked vias, buried vias for compact RF modules.

• Low-Profile Copper for Reduced RF Loss

Lower conductor loss for high-frequency transmission lines.

• Controlled Thermal Pressing for RF Laminates

Prevents voiding and ensures long-term laminate stability.

• Resin-Filled & Capped Vias

Stable RF transitions in antenna feed networks.

• RF Testing & Validation

VNA impedance verification, RF line attenuation measurement.

Keyword density: RF PCB manufacturing / RO4350B PCB fabrication / high-frequency PCB / RF stackup design / KKPCB RF solutions.

6. Conclusion: RO4350B + KKPCB = Superior High-Frequency Antenna Performance

RO4350B PCB laminates deliver:

-

High RF power handling

-

Low-loss high-frequency performance

-

Exceptional phase stability

-

Predictable impedance

-

High-density RF routing capability

Together with KKPCB’s advanced RF PCB manufacturing, HDI capability, and precision impedance control, engineers can build reliable, high-efficiency antenna modules for 5G, radar, satellite, microwave, and high-frequency IoT systems.

If your project requires high-frequency stability, low-loss performance, and high-power RF capability, KKPCB can provide complete stackup engineering, RF optimization, and mass-production support.