High TG materials play a decisive role in modern PCB designs where elevated operating temperatures, complex multilayer stackups, and long-term reliability are mandatory. As electronic systems continue to push higher power density and tighter integration, conventional low-TG laminates increasingly become a limiting factor in both manufacturing yield and field performance.

Understanding the Importance of TG in PCB Materials

The glass transition temperature (TG) marks the point at which a resin system transitions from a rigid, glass-like state to a softer, rubber-like condition. Once a PCB operates near or above this threshold, mechanical strength, dimensional stability, and electrical consistency degrade rapidly.

High TG materials are engineered to maintain stability well above standard operating and assembly temperatures, typically offering:

-

TG values ≥170°C, with advanced systems exceeding 200°C

-

Reduced resin softening during reflow and thermal cycling

-

Improved resistance to delamination and via fatigue

For high-reliability electronics, TG is not a theoretical parameter—it directly impacts manufacturability and lifecycle performance.

Thermal and Mechanical Stability Advantages

High TG materials significantly reduce the risks associated with thermal stress, including:

-

Board warpage during multilayer lamination

-

Plated through-hole cracking caused by CTE mismatch

-

Pad lifting and solder joint fatigue

-

Long-term mechanical deformation under sustained heat

By maintaining rigidity at elevated temperatures, high TG PCB materials preserve layer registration accuracy and via integrity, especially in high layer count and HDI PCB designs.

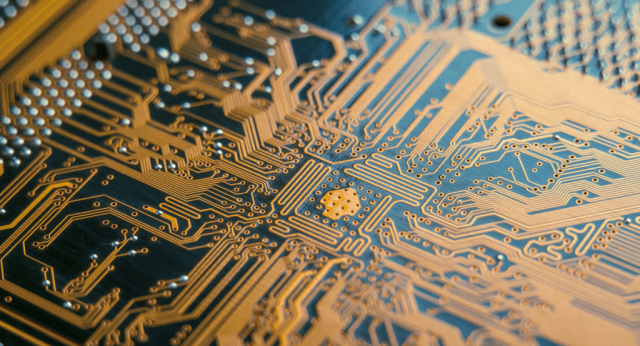

Electrical Performance at Elevated Temperatures

Electrical performance is closely linked to resin behavior. When operating near TG, dielectric properties may drift, causing:

-

Impedance instability

-

Increased signal loss

-

Timing skew in high-speed channels

High TG materials offer stable dielectric constant (Dk) and dissipation factor (Df) across wide temperature ranges, making them suitable for:

-

High-speed digital backplanes

-

Controlled impedance PCB designs

-

Mixed-signal and RF-integrated systems

This stability ensures consistent signal integrity even under thermal stress and continuous operation.

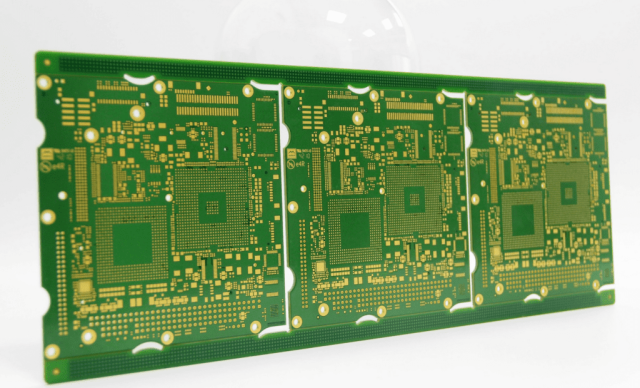

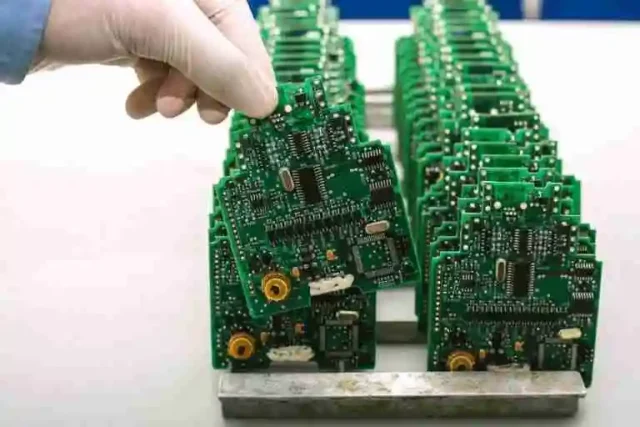

Manufacturing Benefits of High TG Materials

From a PCB fabrication standpoint, high TG materials improve process control and yield by:

-

Supporting higher lamination temperatures

-

Tolerating multiple reflow cycles without degradation

-

Enabling thicker copper and complex stackups

-

Reducing scrap caused by delamination or distortion

These advantages are particularly valuable in automotive, industrial, aerospace, and power electronics PCBs, where reliability standards are strict and failure margins are low.

Typical Applications of High TG Materials

High TG materials are widely applied in:

-

High-speed networking and server PCBs

-

Power control and inverter boards

-

Automotive electronics and ADAS systems

-

Industrial automation and control equipment

-

Aerospace and defense electronics

In all these applications, high TG materials act as a foundation for thermal robustness and structural integrity, enabling advanced electrical performance without compromising reliability.

Engineering Perspective

High TG materials should be selected as part of a system-level thermal and mechanical strategy, not simply as an upgrade from standard FR-4. When combined with optimized stackup design, controlled impedance routing, and disciplined manufacturing processes, high TG materials significantly enhance PCB durability, performance consistency, and service life.

KKPCB supports high TG PCB projects through material selection consultation, stackup engineering, and precision manufacturing control, ensuring stable performance for demanding electronic applications.