High TG materials are specialized PCB laminates and prepregs engineered to operate reliably under elevated temperatures, repeated thermal cycling, and high-density multilayer stackups. TG, or glass transition temperature, defines the point at which the resin matrix softens, directly affecting mechanical stability, dimensional integrity, and electrical performance. In advanced electronic systems, selecting high TG materials is a critical engineering decision, not merely a material upgrade.

Why High TG Materials Are Needed

Modern PCBs in applications such as high-speed computing, power electronics, automotive, and aerospace systems frequently experience high thermal loads due to device power dissipation or soldering processes. Standard FR-4 or low-TG laminates can suffer from:

-

Warpage and board deformation

-

Solder joint fatigue

-

Impedance drift and signal degradation

-

Reduced long-term reliability under thermal stress

High TG materials mitigate these issues, maintaining structural and electrical integrity even during repeated high-temperature cycles.

Electrical and Thermal Characteristics

High TG materials typically offer:

-

Glass transition temperatures above 170°C, with some materials exceeding 200°C

-

Low coefficient of thermal expansion (CTE) for dimensional stability

-

Stable dielectric constant (Dk) and low dissipation factor (Df) across temperature ranges

-

High Tg laminates suitable for high-speed, high-frequency signal integrity

These properties ensure that high TG PCBs maintain both electrical performance and mechanical reliability in challenging thermal environments.

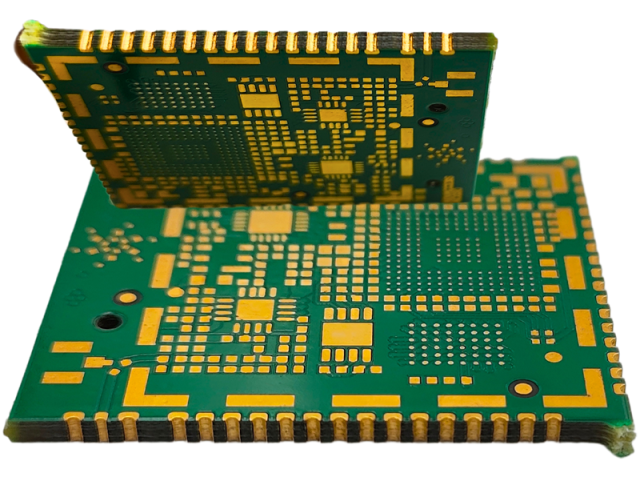

Mechanical Stability in Multilayer Designs

In multilayer and HDI PCBs, thermal mismatch between layers can induce warpage, delamination, or via cracking. High TG materials reduce these risks by:

-

Preserving board flatness during lamination and reflow processes

-

Minimizing CTE mismatch with copper and component substrates

-

Supporting dense via structures and fine-pitch routing without deformation

Proper stackup design leveraging high TG laminates ensures consistent layer-to-layer alignment and mechanical integrity in complex PCB architectures.

Signal Integrity and High-Speed Applications

For high-speed digital and RF PCBs, electrical performance is sensitive to dielectric variation under thermal stress. High TG materials provide:

-

Stable impedance under elevated temperatures

-

Low dielectric loss for high-frequency traces

-

Minimal phase distortion over repeated thermal cycles

-

Reliable high-speed interconnects for GHz-class signals

This combination of thermal and electrical stability is essential in 5G modules, RF front-ends, and server-grade computing boards.

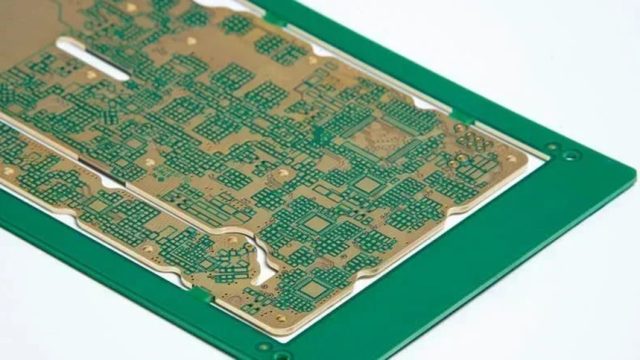

Manufacturability and Process Considerations

High TG materials are compatible with advanced PCB manufacturing techniques, including:

-

Fine-line and microvia HDI fabrication

-

Controlled lamination for multilayer stackups

-

High-temperature reflow and wave soldering

-

Electrical testing for impedance and signal integrity validation

Selecting the appropriate high TG laminate ensures manufacturing consistency and yield while maintaining electrical and mechanical reliability.

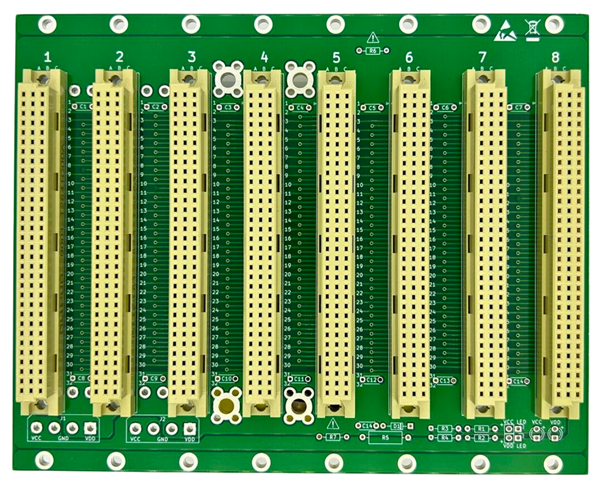

Typical Applications

High TG materials are widely used in:

-

High-speed digital boards (DDR, FPGA, CPU interconnects)

-

RF and microwave PCB designs

-

Power electronics and automotive control modules

-

Aerospace and defense electronics

-

High-reliability industrial control systems

In these applications, high TG materials enable elevated temperature operation, dimensional stability, and long-term reliability, supporting system-level performance goals.

Engineering Perspective

High TG materials should be treated as a system-level enabler rather than just a resin upgrade. Their selection impacts thermal, mechanical, and electrical behavior across the entire PCB and the final electronic system. When combined with controlled impedance stackups and disciplined manufacturing, high TG materials provide a reliable foundation for complex, high-performance PCBs.

KKPCB supports high TG PCB projects through laminate selection guidance, thermal-mechanical stackup engineering, and process-aligned manufacturing control, ensuring consistent high-temperature performance in advanced electronic systems.