As data rates continue to increase, validating high-speed digital interfaces requires test platforms that introduce minimal distortion. The High Speed Test PCB is engineered to act as a transparent signal medium, enabling accurate characterization of high-speed devices and systems.

A well-designed high speed test PCB ensures that test results reflect real device performance rather than PCB-induced errors.

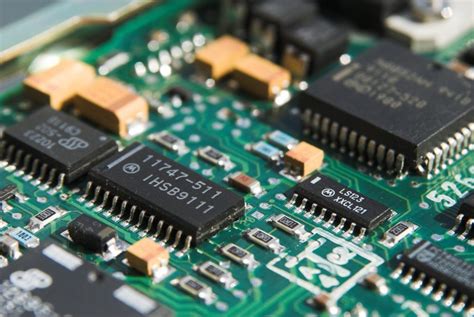

What Is a High Speed Test PCB?

A High Speed Test PCB is a test-focused printed circuit board optimized for validating high-speed digital signals such as SerDes, DDR, PCIe, USB, and Ethernet. Unlike RF-oriented test boards, it emphasizes timing accuracy and signal fidelity in the time domain.

Why High Speed Test PCBs Are Essential

High-speed testing demands:

-

Minimal signal distortion and attenuation

-

Tight control of skew and jitter

-

Repeatable electrical behavior across test cycles

High speed test PCBs provide a stable and predictable test environment.

Controlled Impedance and Differential Pair Design

Accurate impedance control is fundamental. High speed test PCBs focus on:

-

Tight tolerance single-ended and differential impedance

-

Matched differential pair geometry

-

Stable reference planes

Consistent impedance ensures clean eye diagrams and BER results.

Length Matching and Timing Control

Timing accuracy is critical at high data rates. High speed test PCBs use:

-

Precise trace length matching

-

Symmetrical routing paths

-

Delay tuning where necessary

These techniques minimize skew and timing mismatch.

Low-Loss Materials for High-Speed Digital Signals

Material selection affects signal quality. High speed test PCBs may use:

-

Low-Df laminates to reduce attenuation

-

Smooth copper foil for reduced conductor loss

-

Hybrid stackups balancing cost and performance

Low-loss materials improve signal margin.

Via Design and Signal Transitions

Vias can introduce discontinuities. High speed test PCBs mitigate this by:

-

Short via stubs or back-drilling

-

Optimized via pad and anti-pad design

-

Grounded return vias near signal transitions

Clean transitions preserve eye opening.

Crosstalk and Noise Suppression

Dense high-speed routing increases coupling risk. Effective solutions include:

-

Adequate spacing between signal channels

-

Ground stitching and reference continuity

-

Isolation between noisy and sensitive signals

Noise control ensures repeatable test results.

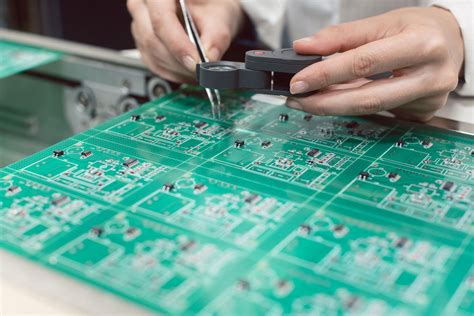

Manufacturing Precision and Electrical Verification

High speed test PCBs require:

-

Tight process tolerances

-

Impedance coupon testing

-

Electrical and signal verification

Manufacturing accuracy directly impacts test reliability.

Typical Applications of High Speed Test PCBs

High speed test PCBs are commonly used in:

-

High-speed interface validation

-

Semiconductor characterization

-

Data center and networking hardware testing

-

Functional and compliance testing platforms

Each application depends on consistent signal behavior.

Selecting a High Speed Test PCB Manufacturer

When choosing a high speed test PCB supplier, look for:

-

Experience with high-speed digital designs

-

Controlled impedance and low-loss fabrication capability

-

Support for prototype and engineering builds

-

Understanding of test-driven design requirements

An experienced partner helps ensure accurate validation.

Conclusion

The High Speed Test PCB is a critical tool for validating modern high-speed digital systems. Through controlled impedance, precise timing control, and low-loss design, high speed test PCBs enable accurate, repeatable, and trustworthy test results.

Partnering with a specialized high speed test PCB manufacturer ensures reliable performance in demanding validation environments.