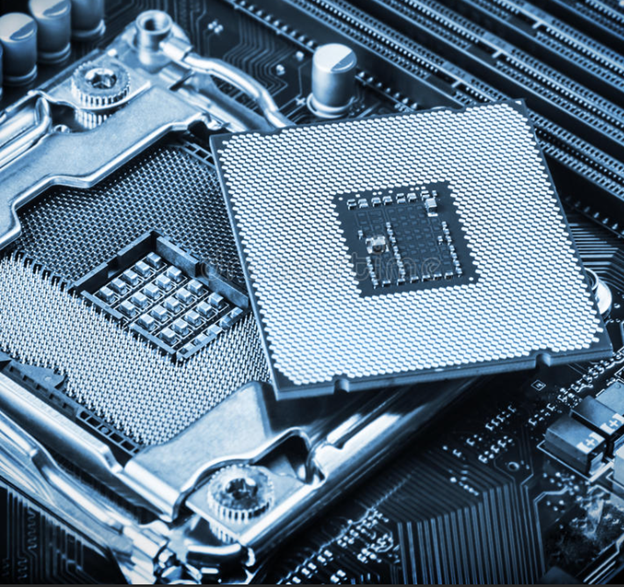

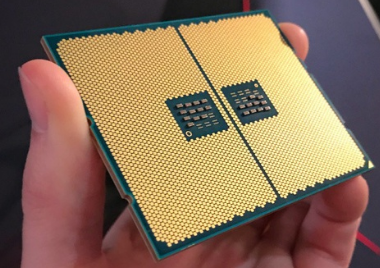

A High Pin Count PCB is designed to support electronic components with a large number of I/O pins, such as high-density BGAs, processors, FPGAs, and ASICs. As modern electronic systems demand higher performance, faster data transfer, and increased functionality, high pin count devices have become increasingly common.

Manufacturing a reliable high pin count PCB requires advanced design techniques, precise manufacturing processes, and strict quality control to ensure electrical performance and long-term reliability.

What Is a High Pin Count PCB?

A High Pin Count PCB is a printed circuit board engineered to accommodate components with hundreds or even thousands of pins. These PCBs must handle dense signal routing, power distribution, and ground management within limited board space.

High pin count PCBs are often combined with HDI technology, fine line routing, microvias, and multilayer stack-ups to meet routing density and signal integrity requirements.

Key Challenges in High Pin Count PCB Design

High-Density Routing

Large pin counts require extremely fine trace widths, tight spacing, and multiple routing layers to fan out signals efficiently.

Signal Integrity and Impedance Control

High-speed signals demand precise controlled impedance to minimize reflection, crosstalk, and timing errors.

Power and Ground Management

Supplying stable power to high pin count devices requires well-designed power planes and low-impedance return paths.

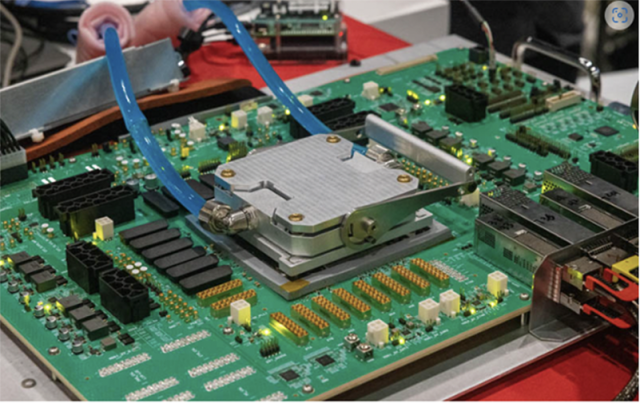

Thermal Management

High pin count components often generate significant heat, requiring effective thermal design to maintain performance and reliability.

Manufacturing Capabilities for High Pin Count PCBs

Producing a high-quality High Pin Count PCB requires advanced manufacturing technology:

-

Multilayer and high layer count PCB fabrication

-

HDI PCB manufacturing with microvias

-

Blind and buried via technology

-

Fine line and space etching

-

Controlled impedance PCB processing

-

Via-in-pad plating and filling

-

Advanced AOI and electrical testing

These capabilities ensure reliable performance in complex, high-density designs.

Materials Used in High Pin Count PCB Manufacturing

Material selection plays a critical role in performance and reliability:

-

High-Tg FR-4 for standard high pin count designs

-

Low-loss materials for high-speed and high-frequency applications

-

Hybrid stack-ups combining RF and digital layers

-

Thick copper layers for power integrity

An experienced high pin count PCB manufacturer assists in selecting materials based on electrical and thermal requirements.

Design Support and Engineering Collaboration

High pin count PCB projects benefit from early and close collaboration with the PCB manufacturer:

-

Stack-up and layer count optimization

-

Fan-out strategy and via structure selection

-

Signal integrity and impedance analysis

-

Power distribution network (PDN) optimization

-

DFM and reliability review

This engineering support improves first-pass success and reduces design risk.

Applications of High Pin Count PCBs

High pin count PCBs are widely used in:

-

Semiconductor test and ATE systems

-

High-performance computing and servers

-

Networking and data center equipment

-

Automotive electronics and ADAS systems

-

Industrial automation and control systems

-

Aerospace and defense electronics

In these applications, PCB performance directly impacts system functionality and reliability.

From Prototype to Volume Production

High pin count PCB development typically begins with prototype builds to validate routing density, signal integrity, and thermal performance. Once approved, designs are transitioned to small-batch or mass production using consistent materials and tightly controlled manufacturing processes.

Partnering with a single supplier from prototype to production ensures stability and long-term quality.

Conclusion

A High Pin Count PCB is essential for supporting today’s most advanced electronic devices and systems. By combining HDI technology, controlled impedance, multilayer construction, and precision manufacturing, professional PCB suppliers deliver high pin count PCBs that meet demanding performance and reliability requirements.

As electronic designs continue to increase in complexity, choosing an experienced high pin count PCB manufacturer is key to achieving successful product development and scalable production.