Testing high-frequency circuits is fundamentally different from testing standard digital electronics. At RF and microwave frequencies, even small PCB variations can introduce loss, phase error, or impedance mismatch that directly distort test results. The High Frequency Test PCB is specifically engineered to provide a stable and predictable platform for accurate RF measurement and validation.

A professionally designed High Frequency Test PCB ensures that measured performance truly reflects the device under test—not the limitations of the test board.

What Is a High Frequency Test PCB?

A High Frequency Test PCB is a specialized printed circuit board used to validate RF, microwave, and high-speed analog circuits. It serves as the electrical interface between:

-

RF test instruments and ATE systems

-

Devices under test (DUTs)

-

Test connectors, probes, or sockets

Unlike application PCBs, high frequency test PCBs prioritize measurement accuracy, low loss, and electrical repeatability.

Why High Frequency Test PCB Quality Is Critical

In high-frequency testing, poor PCB design can cause:

-

Excessive insertion loss

-

Impedance mismatch and signal reflections

-

Phase instability and timing error

A high-quality High Frequency Test PCB minimizes these effects, ensuring consistent and trustworthy measurement results.

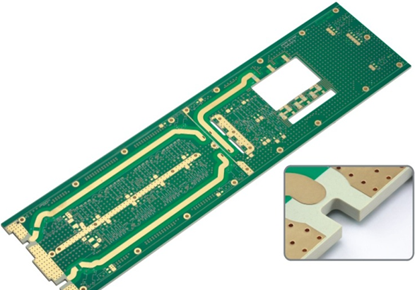

Controlled Impedance and Transmission Line Accuracy

Precise impedance control is the foundation of any High Frequency Test PCB. Key design practices include:

-

Tight control of trace width and dielectric thickness

-

Consistent reference plane spacing

-

Accurate modeling of transmission line structures

Even minor impedance deviations can significantly impact RF test accuracy.

Minimizing Loss at High Frequencies

Signal loss becomes more severe as frequency increases. High Frequency Test PCBs reduce loss by:

-

Using low-loss dielectric materials

-

Optimizing copper surface roughness

-

Keeping RF signal paths as short and direct as possible

Low insertion loss ensures realistic performance evaluation.

Signal Integrity and Crosstalk Control

At RF and microwave frequencies, signal coupling can corrupt measurements. Effective High Frequency Test PCB designs incorporate:

-

Adequate spacing between RF traces

-

Ground isolation structures

-

Dedicated RF reference planes

These measures preserve signal purity during testing.

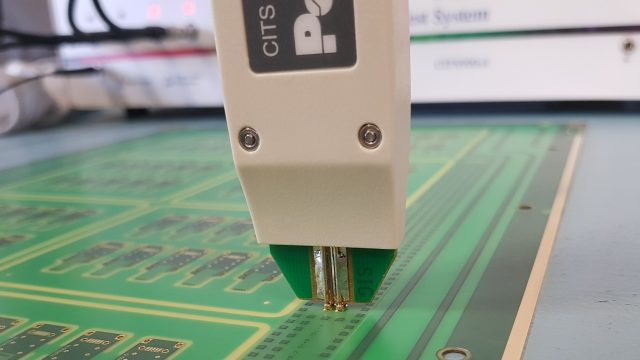

Connector and Interface Design

High-frequency test accuracy depends heavily on interface transitions. A High Frequency Test PCB must ensure:

-

Smooth impedance transition between connectors and PCB traces

-

Proper grounding around RF connectors

-

Mechanical stability to prevent connector movement

Well-designed transitions reduce reflection and phase error.

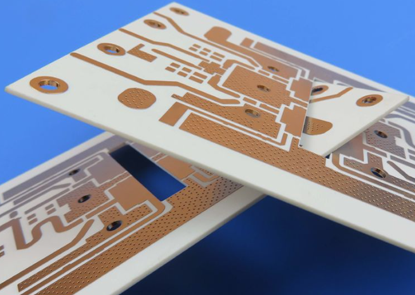

Stackup and Material Selection

Material selection directly affects frequency performance. Common choices for High Frequency Test PCBs include:

-

Rogers and PTFE-based laminates

-

Hybrid stackups combining RF materials and FR-4

-

Symmetrical multilayer constructions for stability

Stable dielectric properties are essential for consistent measurements.

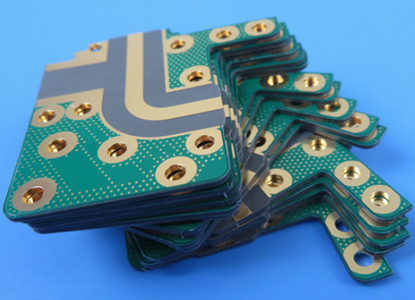

Mechanical Stability and Repeatability

High frequency test PCBs often undergo repeated connections and environmental changes. Reliability depends on:

-

Excellent PCB flatness

-

Balanced stackup to minimize warpage

-

Robust mounting and connector reinforcement

Mechanical consistency ensures electrical consistency.

Manufacturing Precision and Verification

Manufacturing tolerances directly impact RF test accuracy. High-quality High Frequency Test PCBs require:

-

Tight laminate thickness control

-

Accurate etching and drilling

-

Impedance and RF performance verification

Process control is critical for repeatable results.

Typical Applications of High Frequency Test PCBs

High Frequency Test PCBs are widely used in:

-

RF and microwave circuit validation

-

5G and mmWave module testing

-

Antenna and RF front-end evaluation

-

High-speed analog and mixed-signal testing

These applications demand precise, low-loss test environments.

Choosing a High Frequency Test PCB Manufacturing Partner

When selecting a High Frequency Test PCB manufacturer, key factors include:

-

Proven RF and microwave PCB experience

-

Capability with low-loss materials

-

Controlled impedance and RF testing support

-

Engineering collaboration for test optimization

A skilled partner ensures measurement accuracy from prototype to production.

Conclusion

The High Frequency Test PCB is a critical tool for validating RF and microwave designs. By controlling impedance, minimizing loss, and ensuring mechanical and manufacturing consistency, a well-designed test PCB enables accurate, repeatable, and trustworthy high-frequency measurements.

Partnering with an experienced High Frequency Test PCB supplier is essential for reliable RF testing success.