As electronic systems continue to move toward higher speeds and higher frequencies, selecting the right high frequency PCB supplier has become critical for RF, microwave, and millimeter-wave applications. High frequency PCBs require specialized materials, tight impedance control, and advanced manufacturing processes to ensure stable signal performance.

This article outlines what defines a qualified high frequency PCB supplier and how to evaluate potential partners.

What Is a High Frequency PCB Supplier?

A high frequency PCB supplier specializes in manufacturing PCBs designed for RF, microwave, and high-speed digital applications. These suppliers have expertise in:

-

High-frequency laminate materials

-

Impedance-controlled stack-ups

-

Precision fabrication and testing

-

RF performance validation

Unlike standard PCB suppliers, high frequency PCB suppliers focus on performance-critical designs.

Key Capabilities of a High Frequency PCB Supplier

1. Expertise in High Frequency Materials

A reliable high frequency PCB supplier should support a wide range of RF materials, including:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

Taconic RF materials

-

Hybrid stackups combining RF materials with FR-4

Material expertise ensures low signal loss, stable impedance, and predictable RF performance.

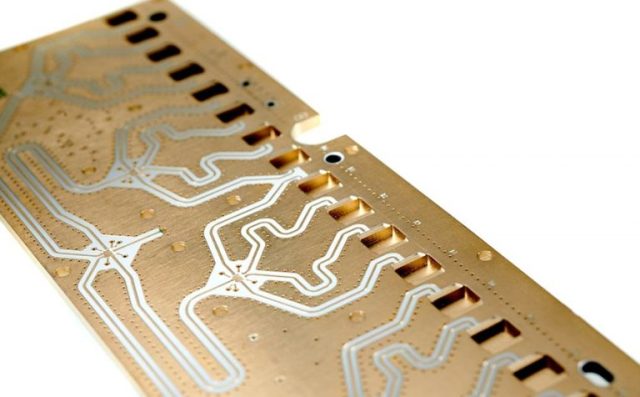

2. Accurate Impedance Control

Impedance control is essential for high frequency circuits:

-

Controlled impedance traces reduce signal reflection

-

Tight tolerance (±5% or better) improves consistency

-

TDR testing verifies actual impedance values

A capable high frequency PCB supplier provides impedance modeling and verification.

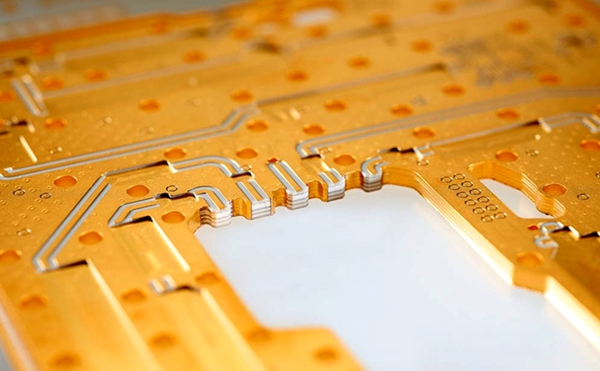

3. Advanced Manufacturing Capability

High frequency PCB manufacturing requires:

-

Precision lamination and etching

-

Fine line width and spacing control

-

Controlled copper thickness and surface finish

-

Stable multilayer stack-up processes

These capabilities ensure reliable electrical and mechanical performance.

Quality Assurance and RF Testing

Top high frequency PCB suppliers implement comprehensive quality control, including:

-

TDR impedance testing

-

Electrical testing and RF validation

-

AOI and X-ray inspection

-

Consistent process monitoring

Quality assurance ensures every PCB meets design specifications.

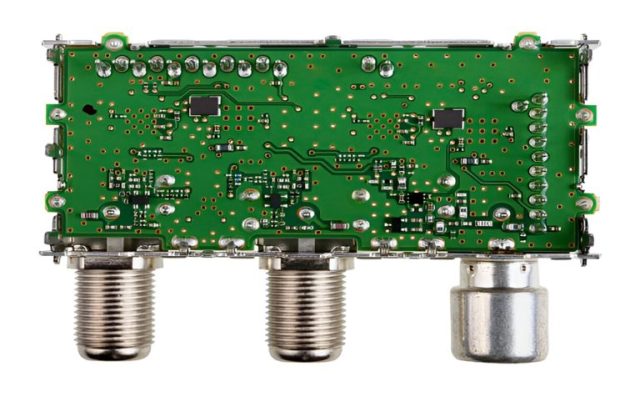

Applications Served by High Frequency PCB Suppliers

High frequency PCBs are widely used in:

-

RF front-end modules

-

5G communication systems

-

Microwave and mmWave circuits

-

Radar and satellite electronics

-

Automotive radar and ADAS

Each application demands low loss, stable impedance, and long-term reliability.

How to Choose the Right High Frequency PCB Supplier

When selecting a supplier, consider:

-

Experience in RF and high frequency PCB manufacturing

-

Material availability and technical support

-

Quality systems and testing capability

-

Lead time, pricing, and scalability

-

Engineering and DFM support

Choosing the right partner reduces risk and improves product success.

Conclusion

Selecting a reliable high frequency PCB supplier is essential for successful RF and microwave product development. From material selection and impedance control to advanced manufacturing and testing, a qualified supplier ensures consistent performance and production reliability.

By working with an experienced high frequency PCB supplier, companies can confidently bring high-performance RF products from design to mass production.