As electronic systems continue to move toward higher frequencies and faster data rates, PCB performance has become a decisive factor in overall system reliability. Choosing a professional high frequency PCB supplier is essential for applications requiring low signal loss, stable impedance, and consistent manufacturing quality.

A qualified high frequency PCB supplier provides not only PCB fabrication, but also RF engineering support, material expertise, and scalable production solutions for demanding RF and high-speed applications.

What Is a High Frequency PCB Supplier?

A high frequency PCB supplier specializes in manufacturing printed circuit boards designed to operate at GHz-level and microwave frequencies. Compared with standard PCB suppliers, a high frequency PCB supplier focuses on:

-

Low-loss RF material processing

-

Controlled impedance PCB manufacturing

-

Precision stack-up design and simulation

-

RF-focused quality control and testing

-

Prototype, small batch, and mass production support

These capabilities ensure reliable high-frequency signal transmission.

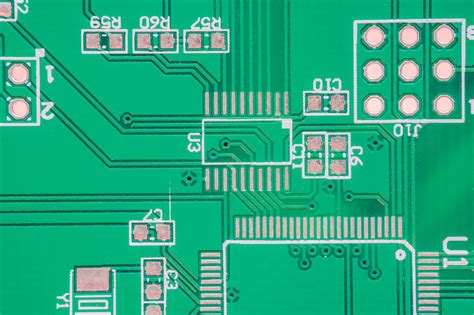

RF Materials Supported by High Frequency PCB Suppliers

Material selection is critical for high-frequency performance. A professional high frequency PCB supplier typically supports a wide range of RF materials, including:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

PTFE-based substrates for microwave and mmWave designs

-

Taconic RF materials such as RF-35

-

Hybrid stackups combining RF materials with FR-4

These materials offer low dielectric loss (Df), stable dielectric constant (Dk), and excellent frequency stability.

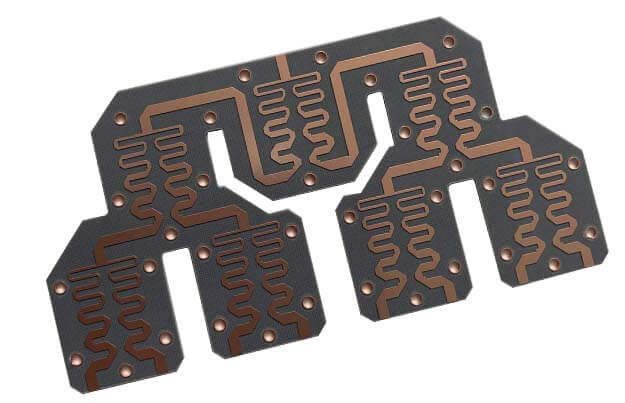

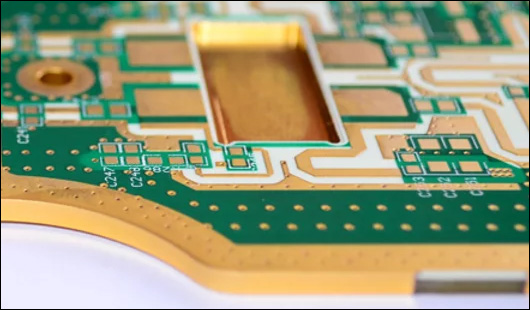

Controlled Impedance and Signal Integrity

Accurate impedance control is a core capability of a reliable high frequency PCB supplier.

Professional suppliers provide:

-

Stack-up modeling and impedance calculation

-

Tight control of trace width, spacing, and dielectric thickness

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing with detailed reports

This ensures minimal signal reflection and optimized signal integrity.

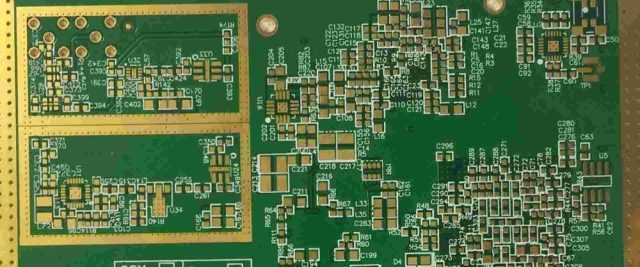

Manufacturing Precision and Quality Assurance

High-frequency PCB performance depends heavily on manufacturing consistency. Experienced high frequency PCB suppliers implement:

-

High-precision lamination and fine-line etching

-

Copper surface roughness control to reduce conductor loss

-

AOI, X-ray inspection, and electrical testing

-

Stable process control across production batches

Strict quality assurance ensures reliable PCB performance from prototype to mass production.

Applications Served by High Frequency PCB Suppliers

High frequency PCBs are widely used in:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

High-speed networking and data transmission equipment

-

Automotive radar and advanced sensing systems

These applications require low loss, high stability, and manufacturing precision.

How to Choose the Right High Frequency PCB Supplier

When selecting a high frequency PCB supplier, evaluate:

-

Experience in RF and microwave PCB manufacturing

-

Support for low-loss materials and hybrid stackups

-

Impedance control and RF testing capability

-

Engineering support and fast DFM feedback

-

Flexible production capacity from prototype to volume

The right supplier reduces technical risk and shortens time-to-market.

Conclusion

A professional high frequency PCB supplier plays a critical role in enabling RF, microwave, and high-speed electronic systems. Through advanced RF materials, precise impedance control, disciplined manufacturing processes, and strict quality assurance, experienced suppliers deliver high-performance PCB solutions.

By partnering with a trusted high frequency PCB supplier, companies can confidently design, manufacture, and scale high-frequency electronic products with consistent quality and performance.