As signal frequencies continue to increase in modern electronics, PCB performance has become a critical factor in overall system reliability. Choosing a professional high frequency PCB supplier is essential for achieving low signal loss, stable impedance, and consistent manufacturing quality in RF, microwave, and high-speed applications.

A qualified high frequency PCB supplier provides not only fabrication services, but also engineering support, RF material expertise, and scalable production solutions.

What Defines a High Frequency PCB Supplier?

A high frequency PCB supplier specializes in manufacturing printed circuit boards designed for GHz-level and microwave frequency operation. Key capabilities include:

-

Low-loss RF material processing

-

Controlled impedance PCB manufacturing

-

Precision stack-up design and modeling

-

RF-focused quality control and testing

-

Prototype and volume production support

These capabilities ensure reliable high-frequency signal transmission.

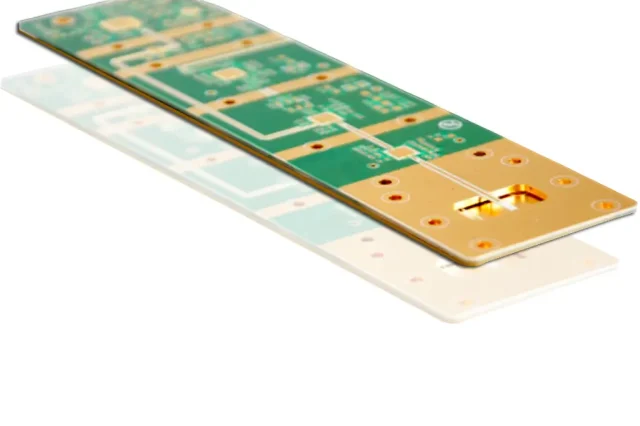

RF Materials Supported by High Frequency PCB Suppliers

Material selection is the foundation of high-frequency PCB performance. A professional high frequency PCB supplier typically supports:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

PTFE-based materials for microwave and mmWave designs

-

Taconic RF materials such as RF-35

-

Hybrid stackups combining RF materials with FR-4

These materials offer low dielectric loss (Df), stable dielectric constant (Dk), and excellent high-frequency stability.

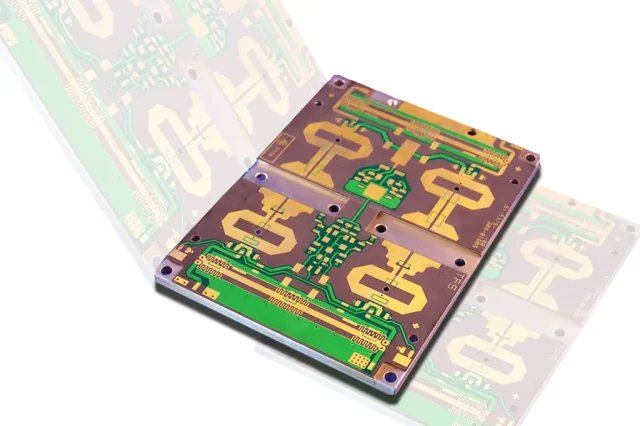

Controlled Impedance and Signal Integrity

Accurate impedance control is essential for RF and high-speed designs. A reliable high frequency PCB supplier provides:

-

Stack-up simulation and impedance calculation

-

Tight control of trace width, spacing, and dielectric thickness

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing and detailed reports

These processes minimize signal reflection and insertion loss.

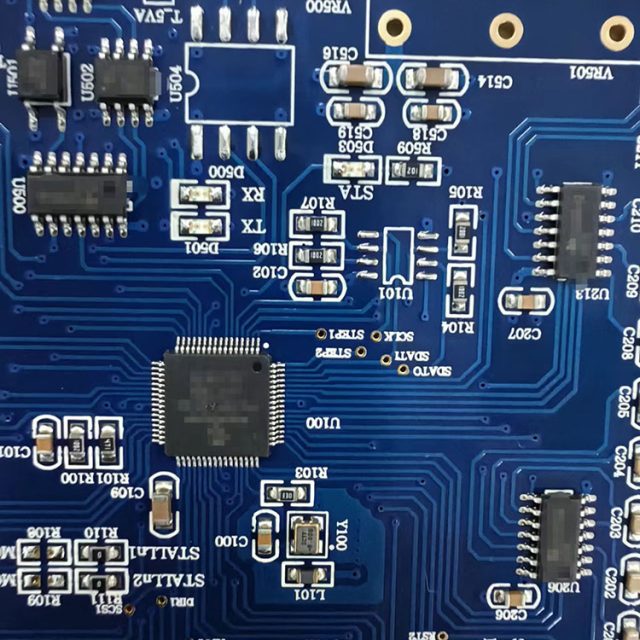

Manufacturing Precision and Quality Assurance

High-frequency performance depends heavily on manufacturing consistency. Professional high frequency PCB suppliers implement:

-

Precision lamination and etching

-

Copper surface roughness control to reduce conductor loss

-

AOI and X-ray inspection

-

Electrical and RF performance testing

Strict quality assurance ensures stable performance across production batches.

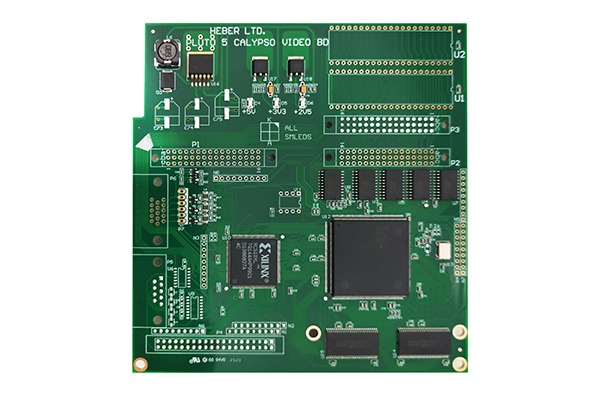

Applications Served by High Frequency PCB Suppliers

High frequency PCBs are widely used in:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

High-speed networking and data transmission equipment

-

Automotive radar and advanced sensing systems

These applications demand low loss, high stability, and manufacturing precision.

How to Choose the Right High Frequency PCB Supplier

When selecting a high frequency PCB supplier, consider:

-

Experience with RF and microwave PCB manufacturing

-

Support for low-loss materials and hybrid stackups

-

Impedance control and testing capability

-

Engineering communication and DFM support

-

Flexible production capacity from prototype to volume

The right supplier reduces technical risk and accelerates time-to-market.

Conclusion

A professional high frequency PCB supplier plays a crucial role in enabling reliable RF, microwave, and high-speed electronic systems. Through advanced materials, precise impedance control, disciplined manufacturing processes, and strict quality assurance, experienced suppliers deliver high-performance PCB solutions.

By partnering with a trusted high frequency PCB supplier, companies can confidently develop and scale high-frequency electronic products with consistent quality and performance.