As wireless communication, 5G, radar, and high-speed electronics continue to evolve, the demand for a reliable high frequency PCB manufacturer has increased significantly. High frequency PCBs operate in GHz and millimeter-wave ranges, where signal integrity, material stability, and manufacturing precision are critical.

This article explains what defines a high frequency PCB manufacturer, the key capabilities required, and how to choose the right partner for RF and microwave projects.

What Is a High Frequency PCB Manufacturer?

A high frequency PCB manufacturer specializes in producing PCBs designed for RF, microwave, and high-speed digital circuits. Unlike standard PCB manufacturers, high frequency PCB manufacturers focus on:

-

Low-loss RF materials

-

Tight impedance control

-

Precision fabrication processes

-

Advanced RF testing and quality control

These capabilities ensure stable signal transmission and reliable performance at high frequencies.

Core Capabilities of a High Frequency PCB Manufacturer

1. Expertise in High Frequency Materials

Material selection is fundamental in high frequency PCB manufacturing. A professional manufacturer supports materials such as:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

Taconic RF materials

-

PTFE-based laminates

-

Hybrid stackups combining RF materials with FR-4

Low dielectric constant (Dk) and low dissipation factor (Df) help minimize signal loss and improve RF performance.

2. Precise Impedance Control

Accurate impedance control is essential for high frequency circuits:

-

Controlled trace geometry and stack-up design

-

Tight impedance tolerance (±5% or better)

-

TDR impedance measurement and verification

A qualified high frequency PCB manufacturer ensures consistent impedance across production batches.

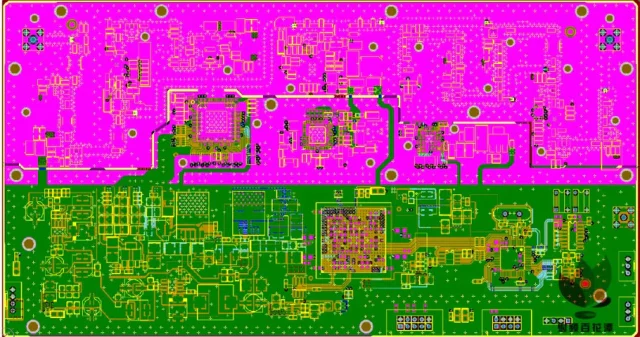

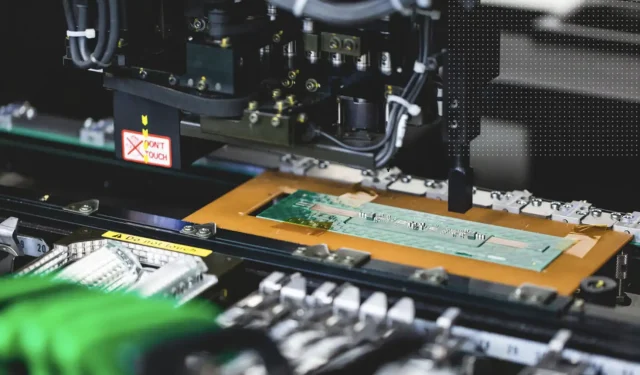

3. Advanced Manufacturing Processes

High frequency PCB manufacturing requires advanced process control, including:

-

Precision lamination and etching

-

Fine line width and spacing capability

-

Controlled copper thickness and surface finishes

-

Stable multilayer stack-up production

These processes ensure electrical accuracy and mechanical reliability.

Quality Assurance and RF Testing

Leading high frequency PCB manufacturers implement strict quality assurance systems:

-

TDR impedance testing

-

Electrical and RF performance testing

-

AOI and X-ray inspection

-

Reliability and consistency checks

Comprehensive testing ensures each PCB meets design and performance requirements.

Applications of High Frequency PCBs

High frequency PCBs manufactured by experienced suppliers are widely used in:

-

RF front-end modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

Radar and satellite electronics

-

Automotive radar and ADAS

Each application requires low loss, stable impedance, and long-term reliability.

How to Choose the Right High Frequency PCB Manufacturer

When selecting a manufacturer, consider:

-

Proven experience in RF and microwave PCB production

-

Material sourcing and processing expertise

-

Impedance control and RF testing capability

-

Lead time, scalability, and pricing transparency

-

Engineering and DFM support

Choosing the right high frequency PCB manufacturer reduces risk and improves product success.

Conclusion

A professional high frequency PCB manufacturer plays a critical role in delivering reliable RF and microwave products. From advanced materials and impedance control to precision fabrication and testing, manufacturing expertise directly impacts performance and quality.

By partnering with an experienced high frequency PCB manufacturer, companies can confidently move from prototype to mass production while meeting demanding high-frequency performance requirements.