In high-speed communications, radar systems, 5G infrastructure, and other cutting-edge electronics, the role of a high frequency PCB manufacturer is more important than ever. High frequency PCBs operate at gigahertz (GHz) and millimeter-wave frequencies, requiring precision design, specialized materials, and advanced fabrication techniques that differ significantly from standard PCB production.

Selecting the right manufacturer influences not only performance but also cost, delivery time, and long-term reliability.

What Defines a High Frequency PCB Manufacturer?

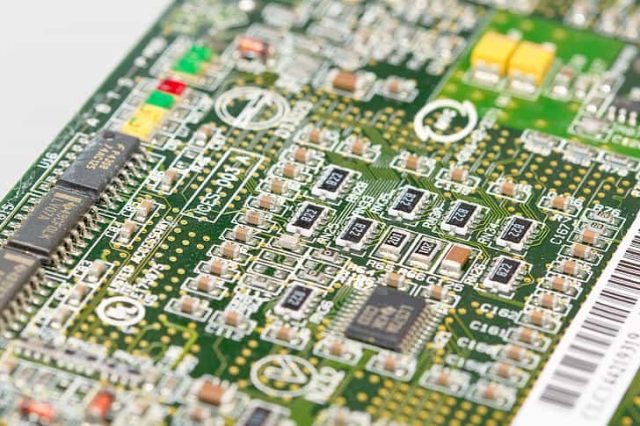

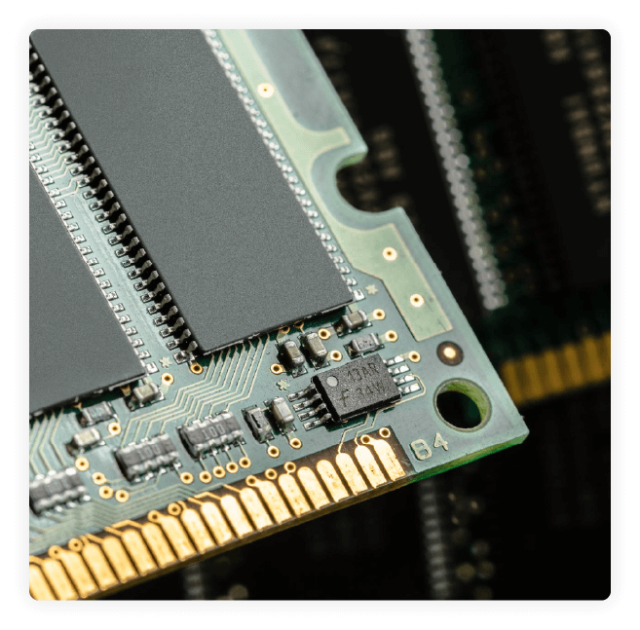

A high frequency PCB manufacturer specializes in producing PCBs designed for RF, microwave, and high-speed digital applications. These manufacturers must have expertise in:

-

Advanced materials like Rogers, PTFE, and ceramic-based laminates

-

Tight impedance control and RF signal integrity

-

Precision fabrication processes

-

High-frequency testing and quality assurance

Manufacturers with these capabilities help engineers realize the full potential of high-frequency and RF designs.

Key Factors When Choosing a High Frequency PCB Manufacturer

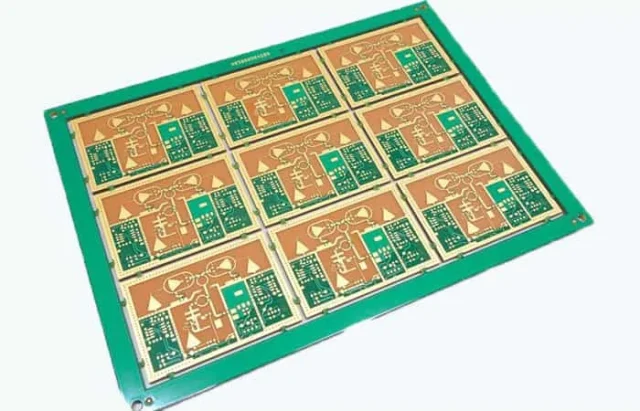

1. Expertise in High Frequency Materials

A reliable high frequency PCB manufacturer should be proficient with materials that have:

-

Low dielectric constant (Dk)

-

Low dissipation factor (Df)

-

Stable performance across frequency and temperature ranges

Common materials include:

-

Rogers laminates for stable impedance and low-loss performance

-

PTFE-based materials for ultra-high-frequency applications

-

Hybrid stackups that balance performance with cost

The right material choice ensures minimal signal loss, effective impedance control, and reliable operation in RF/microwave environments.

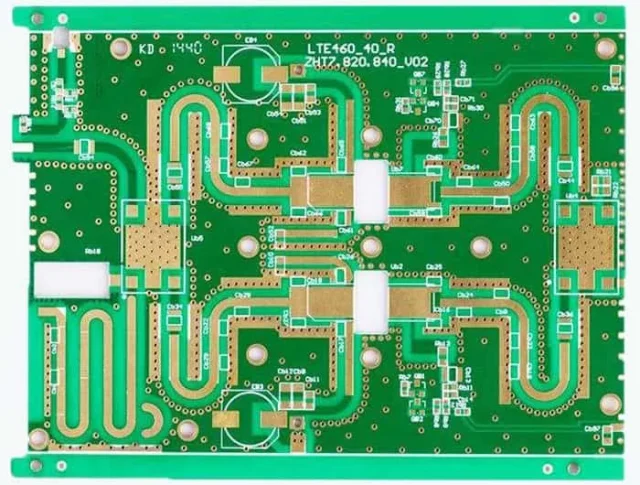

2. Precise Impedance Control Capability

Impedance control is fundamental for high frequency PCB performance. A strong manufacturer must demonstrate:

-

Accurate impedance modeling and simulation

-

Tight tolerance capabilities such as ±5% or better

-

RF-specific testing using tools like Time Domain Reflectometry (TDR)

Effective impedance control reduces signal reflection, improves signal integrity, and ensures predictable performance across production batches.

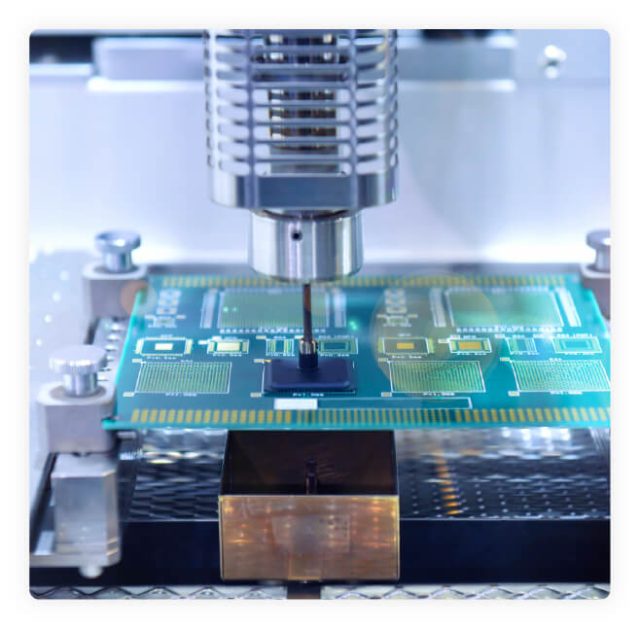

3. Advanced Manufacturing and Fabrication Techniques

Microwave and RF PCB production demand advanced processes including:

-

High-precision lamination and etching

-

Fine line width and spacing control

-

Controlled copper plating and surface finish

-

Stable multilayer stackup processes

Manufacturers with these capabilities deliver boards that meet rigorous electrical and mechanical specifications.

Quality Assurance and RF Testing

Top high frequency PCB manufacturers implement robust quality assurance, including:

-

TDR and network analysis for impedance verification

-

AOI and X-ray inspection for assembly quality

-

Environmental and thermal stress testing

-

Performance validation in real-world RF conditions

These tests ensure that every board meets design specifications and reliability expectations.

Applications of High Frequency PCBs

High frequency PCBs from experienced manufacturers are used in:

-

RF front-end modules

-

Wireless communication systems (including 5G)

-

Radar and satellite electronics

-

Automotive radar and ADAS

-

Aerospace and defense systems

In each of these applications, performance demands precision and reliability that only specialized high frequency PCB manufacturers can deliver.

Conclusion

Choosing the right high frequency PCB manufacturer is essential for successful RF and microwave product development. Evaluate prospective partners based on material expertise, impedance control capability, manufacturing precision, and quality testing. A trusted manufacturer ensures consistent performance, reliable delivery, and seamless transition from prototype to mass production.

By partnering with an experienced high frequency PCB manufacturer, engineers can reduce development risk, improve signal integrity, and deliver products that meet performance and reliability expectations.