As electronic systems continue to operate at higher frequencies and faster data rates, PCB performance has become a critical factor in system reliability. Choosing a professional high frequency PCB manufacturer is essential for achieving low loss, stable impedance, and consistent quality in RF, microwave, and high-speed electronic applications.

A qualified high frequency PCB manufacturer provides direct factory production, advanced RF expertise, and scalable manufacturing solutions from prototype to mass production.

What Defines a High Frequency PCB Manufacturer?

A high frequency PCB manufacturer specializes in producing PCBs designed to operate at GHz-level, microwave, and mmWave frequencies. Compared with general PCB manufacturers, a high frequency PCB manufacturer focuses on:

-

Low-loss RF material processing

-

Controlled impedance PCB fabrication

-

Precision stack-up design and simulation

-

RF-focused manufacturing process control

-

Strict quality inspection and testing

These capabilities ensure reliable high-frequency signal transmission.

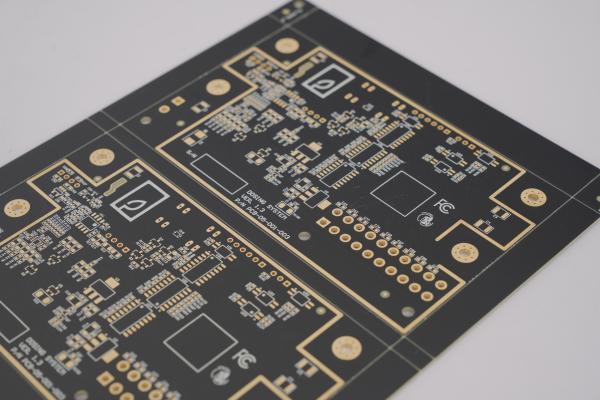

RF and High-Frequency Materials Supported

Material selection is the foundation of high-frequency PCB performance. A professional high frequency PCB manufacturer supports a wide range of RF materials, including:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

PTFE-based materials for microwave and mmWave designs

-

Taconic RF materials such as RF-35

-

Hybrid stackups combining RF materials with FR-4

These materials provide low dielectric loss (Df), stable dielectric constant (Dk), and excellent frequency stability.

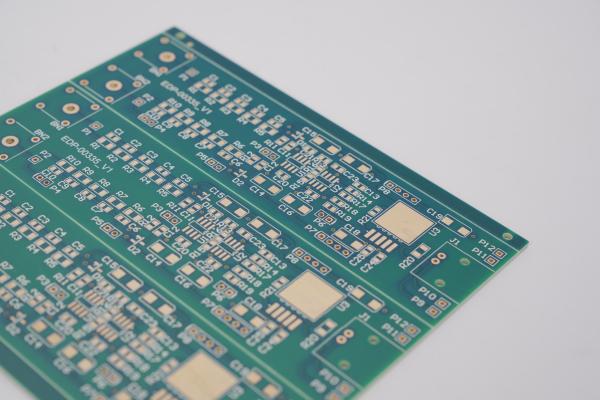

Controlled Impedance Manufacturing Capability

Accurate impedance control is a core strength of an experienced high frequency PCB manufacturer.

Manufacturing processes typically include:

-

Stack-up modeling and impedance calculation

-

Tight control of trace width, spacing, and dielectric thickness

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing and documentation

Precise impedance control minimizes signal reflection and improves signal integrity.

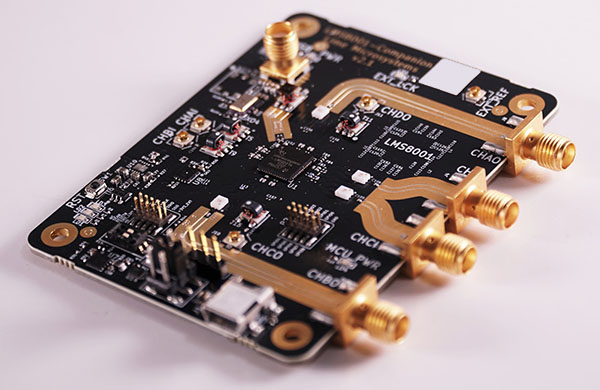

Advanced Manufacturing Processes and Equipment

High-frequency PCB manufacturing requires advanced process control. Professional high frequency PCB manufacturers invest in:

-

High-precision lamination and fine-line etching

-

Copper surface roughness control to reduce conductor loss

-

High-accuracy drilling and via plating

-

AOI, X-ray inspection, and electrical testing

These processes ensure consistent PCB quality across production batches.

Quality Assurance and Reliability Testing

Quality assurance is critical for high-frequency PCBs. A reliable high frequency PCB manufacturer implements:

-

Electrical continuity and isolation testing

-

TDR impedance verification

-

RF performance inspection

-

Process traceability and reliability monitoring

Strict quality control ensures long-term PCB performance and production stability.

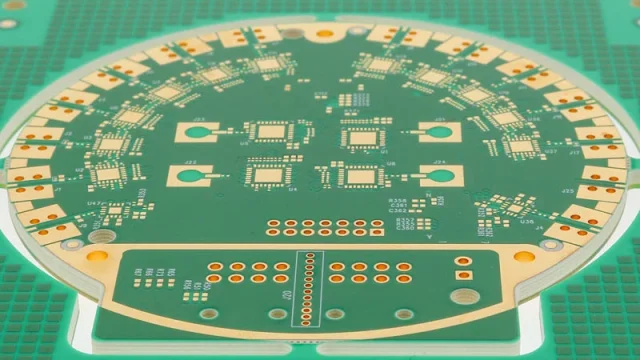

Applications Served by High Frequency PCB Manufacturers

High frequency PCBs are widely used in:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

High-speed networking and data communication equipment

-

Automotive radar and advanced sensing systems

These applications demand low loss, stable impedance, and high manufacturing precision.

Why Choose a Professional High Frequency PCB Manufacturer?

Working directly with an experienced high frequency PCB manufacturer offers:

-

Direct factory pricing and communication

-

Faster engineering support and DFM feedback

-

Stable quality from prototype to mass production

-

Long-term supply chain reliability

A professional manufacturer reduces technical risk and accelerates product development.

Conclusion

A professional high frequency PCB manufacturer plays a vital role in enabling RF, microwave, and high-speed electronic systems. Through advanced RF materials, precise impedance control, disciplined manufacturing processes, and strict quality assurance, experienced manufacturers deliver high-performance PCB solutions.

By partnering with a trusted high frequency PCB manufacturer, companies can confidently design, manufacture, and scale high-frequency electronic products with consistent quality and reliable performance.