High Frequency Laminates: The Foundation for Stable RF & Microwave PCB Performance

With the rapid growth of 5G communication, automotive radar, satellite systems, and high-speed wireless devices, more electronic products are operating at higher frequencies than ever before. In these designs, PCB material performance becomes a critical factor for ensuring stable signal transmission.

Standard FR4 is widely used in general electronics, but it may cause excessive loss and unstable impedance at high frequencies. That’s why engineers choose high frequency laminates—specialized PCB substrate materials designed to deliver low loss and stable electrical behavior for RF and microwave applications.

In this article, we’ll explain what high frequency laminates are, their key advantages, common applications, and how to select the right material for your project.

What Are High Frequency Laminates?

High frequency laminates are PCB materials engineered for circuits operating in RF and microwave frequency ranges. Compared with standard FR4 materials, they offer:

-

Lower dielectric loss (low Df)

-

More stable dielectric constant (stable Dk)

-

Better signal integrity at high frequency

-

Improved reliability for demanding environments

They are commonly used for RF transmission lines, microwave modules, antennas, and high-speed communication circuits.

Why High Frequency Laminates Matter in PCB Design

As frequency increases, PCB performance becomes highly sensitive to material properties. Poor material selection can lead to:

-

Higher insertion loss

-

Signal distortion

-

Impedance mismatch

-

Increased noise and crosstalk

-

Reduced RF efficiency

High frequency laminates help minimize these issues by providing stable electrical performance, allowing RF circuits to work consistently in real-world environments.

Key Benefits of High Frequency Laminates

1. Low Dielectric Loss (Low Df)

High frequency laminates are designed to minimize dielectric loss, which helps:

-

Reduce signal attenuation

-

Improve transmission efficiency

-

Support longer routing distances at high frequency

This is essential for antennas, filters, and RF front-end modules.

2. Stable Dielectric Constant (Dk)

Stable Dk helps ensure consistent impedance and phase response, supporting:

-

Accurate controlled impedance routing

-

Better matching in RF networks

-

Reliable high-frequency performance

For high-frequency circuits, even small Dk variations can cause measurable performance changes.

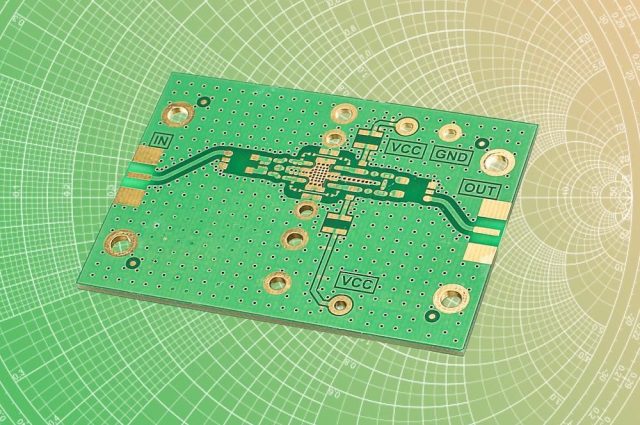

3. Improved Signal Integrity

By reducing loss and stabilizing electrical behavior, high frequency laminates help improve:

-

Signal clarity

-

Phase stability

-

RF power efficiency

-

Repeatability in mass production

This makes them ideal for both prototype and volume manufacturing.

4. Better Reliability for Harsh Conditions

Many high frequency laminates offer good performance under:

-

Thermal cycling

-

Outdoor environments

-

High-power RF operation

-

Automotive and industrial conditions

This improves long-term reliability and reduces field failure risk.

Common Types of High Frequency Laminates

Different high frequency laminates are available to match different performance and cost needs, such as:

PTFE-Based Laminates

Known for ultra-low loss and excellent microwave performance, often used in:

-

High-end microwave circuits

-

Satellite and aerospace RF modules

-

Precision antenna designs

Hydrocarbon/Ceramic Laminates

A popular option balancing performance and manufacturability, used in:

-

5G communication boards

-

Automotive radar modules

-

RF front-end designs

High-Speed Digital Low-Loss Laminates

Optimized for high-speed digital signals and low loss, commonly used in:

-

Data center networking equipment

-

High-speed interconnect designs

-

Advanced communication systems

Typical Applications of High Frequency Laminates

5G Telecom and Communication Systems

High frequency laminates are widely used in:

-

Base station RF boards

-

Small cell modules

-

Massive MIMO antenna systems

They help achieve stable performance and low loss at high frequencies.

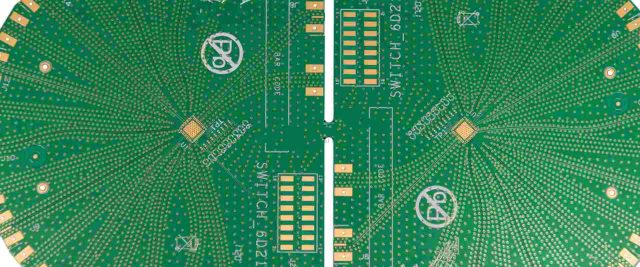

Antenna and RF Front-End Modules

High frequency laminates are ideal for:

-

Antenna arrays

-

RF feed networks

-

Wireless communication modules

Stable Dk and low loss improve antenna efficiency and consistency.

Automotive Radar and ADAS

Radar systems require stable performance in harsh environments. High frequency laminates support:

-

24GHz / 77GHz radar modules

-

Vehicle sensing and detection systems

-

Automotive RF communication circuits

Satellite and Aerospace Electronics

In aerospace and satellite systems, high frequency laminates are used for:

-

Satellite communication modules

-

Microwave navigation equipment

-

High-reliability radar systems

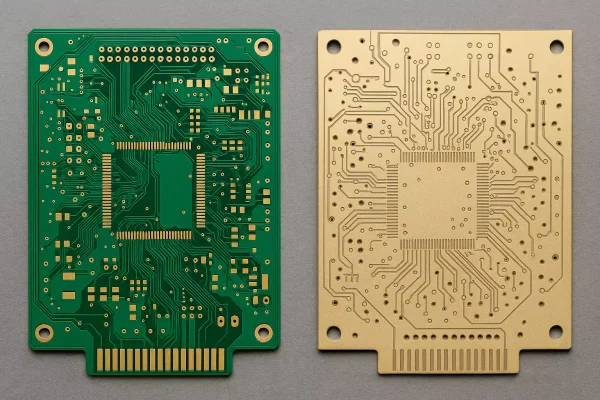

High Frequency Laminates vs FR4: What’s the Difference?

FR4 is suitable for general electronics, but high frequency laminates offer clear advantages for RF designs.

| Feature | FR4 PCB | High Frequency Laminates |

|---|---|---|

| Dielectric Loss | Higher | Lower |

| Dk Stability | Moderate | Better |

| RF Performance | Limited | Excellent |

| Impedance Control | Less stable | More reliable |

| Typical Use | General PCBs | RF / microwave PCBs |

For high-frequency circuits, using the right laminate is essential to achieving stable and repeatable performance.

How to Choose the Right High Frequency Laminate

When selecting high frequency laminates, it’s important to consider:

-

Operating frequency range

-

Target Dk and Df requirements

-

Impedance control and stack-up design

-

Thermal performance and reliability needs

-

Manufacturing compatibility and lead time

-

Total project cost and performance targets

An experienced PCB manufacturer can help recommend suitable materials and stack-ups based on your design goals.

Conclusion

High frequency laminates are essential for RF and microwave PCB designs requiring low loss, stable dielectric performance, and reliable signal integrity. They are widely used in 5G systems, antennas, radar modules, satellite communication, and advanced wireless electronics, helping engineers achieve consistent high-frequency performance beyond standard FR4.

If your project involves high-frequency circuits and controlled impedance requirements, choosing the right high frequency laminate is a critical step toward success.