What Is a High Current PCB?

A High Current PCB is specifically designed to safely carry and distribute large electrical currents without overheating, voltage drop, or reliability failure. Unlike standard PCBs, a high current PCB focuses on low resistance conductor design, thick copper layers, and enhanced thermal management to ensure stable performance under continuous or peak current loads.

High current PCBs are widely used in power electronics, automotive systems, industrial control, renewable energy, and high-power semiconductor applications, where electrical and thermal stresses are significantly higher than in conventional circuits.

Key Design Challenges of High Current PCB

Designing a reliable high current PCB requires addressing several critical challenges:

-

Current carrying capacity of copper traces and planes

-

Thermal dissipation to prevent hot spots and material degradation

-

Voltage drop control for power efficiency

-

Mechanical reliability under thermal cycling

-

Safety and long-term stability

Without proper design and manufacturing, excessive current can lead to trace delamination, solder joint failure, or catastrophic PCB damage.

High Current PCB Design Solutions

To meet these challenges, KKPCB applies proven high current PCB design techniques:

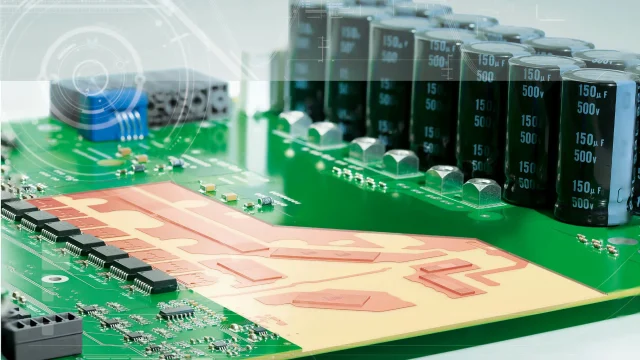

1. Thick Copper PCB Technology

Using 2oz to 20oz copper thickness, thick copper PCBs significantly reduce resistance and improve current capacity. This is one of the most effective solutions for high current PCB applications.

2. Wide Traces and Copper Planes

High current PCB layouts use extra-wide traces, solid copper pours, and power planes to evenly distribute current and minimize localized heating.

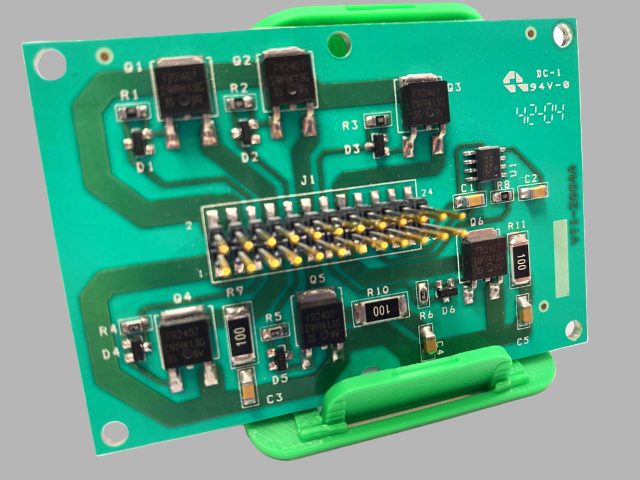

3. Multi-Layer High Current PCB Structures

Multilayer high current PCBs allow dedicated power layers and ground layers, improving electrical performance and heat spreading while maintaining compact board size.

4. Advanced Thermal Management

Thermal vias, heavy copper planes, metal core integration, and optimized stack-ups ensure efficient heat dissipation in high current PCB designs.

5. Reliable Materials Selection

High Tg FR4, metal-core substrates, and specialized laminates are used to enhance thermal stability and long-term reliability in demanding environments.

Applications of High Current PCB

High current PCBs are essential in many high-power systems, including:

-

Power supply and power distribution modules

-

Electric vehicle (EV) power control units

-

Battery management systems (BMS)

-

Industrial motor drives and inverters

-

Renewable energy systems (solar, wind, energy storage)

-

High power LED and lighting systems

-

Semiconductor power testing equipment

KKPCB High Current PCB Manufacturing Capabilities

KKPCB provides end-to-end high current PCB solutions, including:

-

Thick copper PCB fabrication

-

Multilayer high current PCB manufacturing

-

High current PCB prototyping and mass production

-

Precision impedance and resistance control

-

Strict quality inspection and electrical testing

With extensive experience in high current PCB manufacturing, KKPCB ensures every board meets electrical, thermal, and reliability requirements for high-power applications.

Why Choose KKPCB for High Current PCB?

-

Proven expertise in high current and power PCB design

-

Support for thick copper and complex multilayer structures

-

Stable quality for automotive and industrial standards

-

Fast turnaround for prototypes and production

-

Professional engineering support from design to delivery

Conclusion

A well-designed High Current PCB is critical for the safety, efficiency, and longevity of power electronic systems. By combining thick copper technology, optimized layouts, and advanced thermal management, KKPCB delivers reliable high current PCB solutions tailored to demanding applications.

If you are developing a power-intensive product, KKPCB is your trusted partner for high current PCB manufacturing.