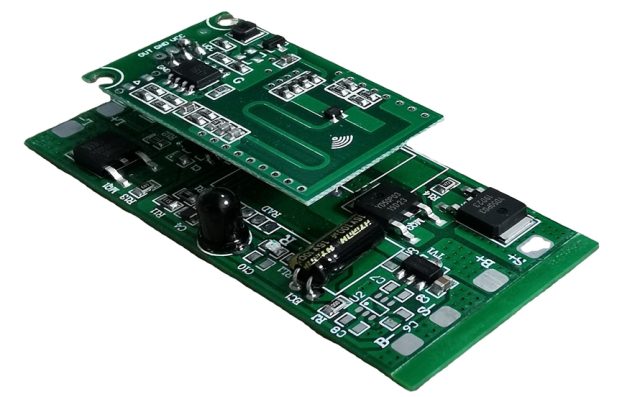

Radar PCB Overview

Radar PCBs represent the pinnacle of high-frequency circuit design, bridging advanced RF engineering and precise manufacturing. These specialized boards operate in the 1 GHz – 77 GHz range, demanding exceptional signal integrity, low loss materials, and extreme reliability — especially in mission-critical applications like automotive radar, aerospace, and defense.

KKPCB has extensive experience in developing radar-grade PCBs for both FMCW (Frequency-Modulated Continuous Wave) and Phased Array radar systems. Our production capabilities and material expertise ensure consistent performance under harsh environmental and electromagnetic conditions.

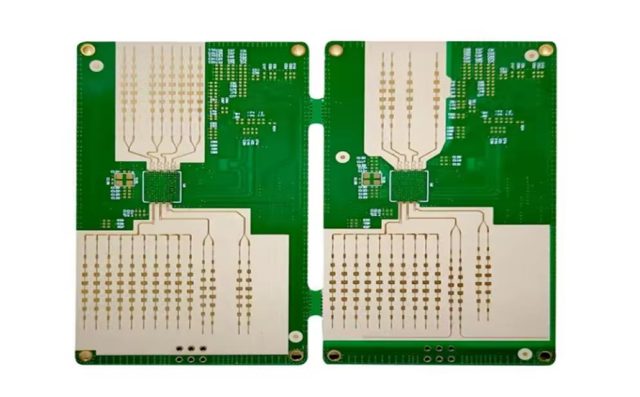

Design Considerations

Designing radar PCBs is a multidisciplinary challenge involving RF engineering, signal integrity, and material science. At KKPCB, our engineers adopt simulation-driven design approaches combined with manufacturing insights to guarantee both performance and yield.

Key design elements include:

-

Optimized Layer Stack: Multi-ground architecture with hybrid material stacks for mixed-signal environments.

-

Material Selection: Ultra-low-loss laminates such as Rogers RO4350B, RO3003, Isola Astra MT77, and Taconic RF-35.

-

Controlled Impedance & Length Matching: Essential for maintaining waveform integrity at GHz frequencies.

-

Shielding & Grounding: Proper via stitching, return path optimization, and antenna isolation techniques to suppress EMI and crosstalk.

Materials Used in Radar PCBs

Choosing the right laminate defines radar PCB performance. KKPCB’s radar solutions use high-grade materials with tight dielectric tolerances and ultra-low dissipation factors:

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) | Key Features |

|---|---|---|---|

| RO4350B | 3.48 | 0.0037 | Cost-effective, hybrid stack compatible |

| RO3003 | 3.00 | 0.0013 | Ultra-low loss, high consistency |

| Astra MT77 | 3.00 | 0.0017 | Wide temperature stability, ideal for automotive radar |

| Taconic RF-35 | 3.50 | 0.0018 | Excellent for FMCW and Doppler radar applications |

Each laminate is chosen based on frequency, power handling, and cost-performance balance to meet project requirements.

Applications of Radar PCBs

Radar PCBs form the backbone of advanced sensing and communication systems. KKPCB manufactures radar PCBs for diverse end-use cases including:

-

Automotive Radar – FMCW and MIMO radars for collision avoidance and ADAS systems.

-

Aerospace & Defense – Long-range pulsed and phased-array radars.

-

5G & Telecommunications – Beam-steering phased-array antennas.

-

Earth Observation & Mapping – SAR (Synthetic Aperture Radar) systems.

Every radar PCB we build undergoes rigorous RF testing and quality control to ensure performance consistency at high frequencies.

Conclusion

Radar PCBs demand an integration of RF design expertise, precision fabrication, and advanced materials.

KKPCB combines simulation-backed engineering, strict impedance control, and hybrid stack manufacturing to deliver radar PCBs that excel in performance, stability, and reliability.

For OEMs and developers seeking a partner with proven RF and microwave PCB experience, KKPCB provides the complete solution — from design to final assembly.