Next-generation 112G/224G SerDes channels push FR-4 far beyond its electrical limits. As data center switching, AI computing, and PCIe-6/7 architectures scale upward, loss tangent, copper roughness, and impedance drift become critical bottlenecks. Megtron 7 PCB laminates—Df 0.0012 class, highly stable Dk, and low copper-permittivity interaction—provide an electrically clean foundation for long-reach PAM4 channels.

KKPCB integrates Megtron 7 PCB stackups with controlled glass styles, ultra-smooth copper, and precision lamination to minimize insertion loss and maintain channel linearity across long backplane runs.

Engineering Challenges for 112G/224G Channels

High-speed systems operating at 56–112 GHz Nyquist frequencies face a cluster of signal-integrity obstacles:

• Loss accumulation caused by copper roughness and dielectric dissipation

• Crosstalk coupling due to dense differential-pair clustering

• Impedance drift triggered by resin-glass variation in multilayer stacks

• PAM4 eye collapse from reflections, skew, and via stubs

• Thermal rise in AI racks causing Dk shift in subpar materials

Megtron 7 PCB materials address these high-speed limits directly with low-loss, stable dielectric behavior ideal for PAM4 modulation.

Material Science — Why Megtron 7 PCB Excels

Megtron 7 PCB laminates deliver:

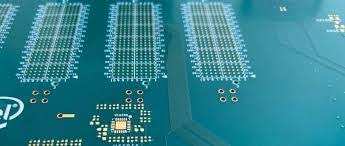

• Ultra-low Df (0.0012–0.0020 range) → reduced insertion loss for 112G/224G

• Tightly controlled Dk (3.3 class) → predictable impedance and low skew

• Low CTE → dimensional stability during reflow

• Low dielectric anisotropy → consistent channel performance across layers

• Reduced glass weave effect → minimized differential skew at long distances

The material’s behavior at ultra-high frequencies makes Megtron 7 PCB one of the few reliable choices for next-generation high-speed infrastructure.

KKPCB Case Study — 224G Switch Backplane PCB

Problem:

A customer’s 224G PAM4 switch backplane using a Megtron-6 equivalent material exhibited excessive IL loss >0.7 dB/in at 26 GHz and unstable impedance across heavy copper zones.

KKPCB Megtron 7 Implementation:

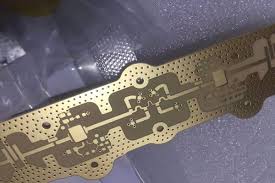

• Optimized Megtron 7 PCB stackup with symmetrical glass styles

• Very-low-profile copper (VLP, Ra <0.7 µm)

• Backdrilled via design reducing stub length below 6 mil

• Tight lamination tolerance ±8 µm

• Distributed via-to-via isolation for deep-reach channels

Results After KKPCB Engineering:

| Parameter | Achieved |

|---|---|

| IL @26 GHz | 0.46 dB/in |

| Crosstalk | –17.5 dB |

| Intra-pair skew | <0.6 ps |

| Return loss | –19.2 dB |

This achieved full margin for 224G PAM4 compliance with additional channel headroom.

Simulation & Stackup Engineering

Using HFSS, ADS, and Sigrity:

• Channel IL flattened by 22% after copper-roughness optimization

• Impedance window held at ±5% across a 24-layer Megtron 7 PCB

• Backdrill depth optimized to avoid 20–30 GHz resonance bands

• Thermal FEM confirmed dielectric stability under 90°C sustained operation

Validation & Reliability Testing

• Thermal cycling –40°C ↔ 110°C: no Dk shift beyond 0.02

• Multi-reflow 260°C × 6 cycles: no warpage

• Vibration testing: no micro-fractures in high-density via arrays

Engineering Summary

Megtron 7 PCB technology enables ultra-low-loss, stable routing for advanced 112G/224G SerDes systems. Through controlled copper roughness, careful glass-style selection, and precise lamination, KKPCB delivers robust, margin-rich high-speed channels suitable for next-generation data center equipment.