Ceramic PCBs represent a significant advancement in electronic circuit technology, purpose-built for environments where heat management, miniaturization, and long-term durability are essential. Unlike conventional FR-4 boards made from organic laminates, ceramic PCBs use high-performance substrates such as Alumina (Al₂O₃), Aluminum Nitride (AlN), and Beryllium Oxide (BeO). These materials deliver outstanding thermal conductivity, mechanical strength, and electrical insulation, making ceramic PCBs the backbone of today’s high-power and high-frequency systems.

In the era of advanced chip integration and surface-mount technology (SMT), the demand for materials that combine compactness, thermal efficiency, and stability has never been greater. Ceramic PCBs from KKPCB provide the perfect solution—offering superior dimensional precision, chemical resistance, and a low coefficient of thermal expansion (CTE) to ensure performance consistency even in the harshest operating conditions.

Types of Ceramic PCBs

Ceramic PCBs are categorized primarily by their fabrication technology, each serving distinct engineering requirements:

1. High-Temperature Co-Fired Ceramic (HTCC)

Manufactured by mixing alumina with binding agents and firing at 1600–1700°C in a hydrogen environment, HTCC boards deliver exceptional mechanical integrity and are commonly used in aerospace, defense, and mission-critical electronics.

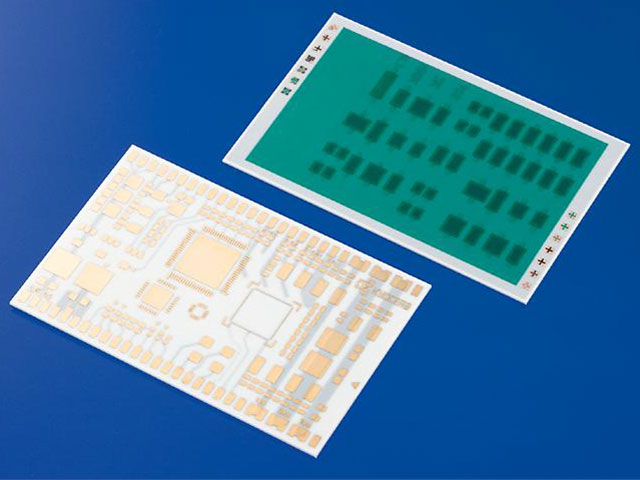

2. Low-Temperature Co-Fired Ceramic (LTCC)

Combining glass and ceramic materials, LTCC is co-fired below 900°C. This method ensures low warpage, high dimensional stability, and excellent compatibility with RF modules, LED assemblies, and miniaturized systems requiring fine signal integrity.

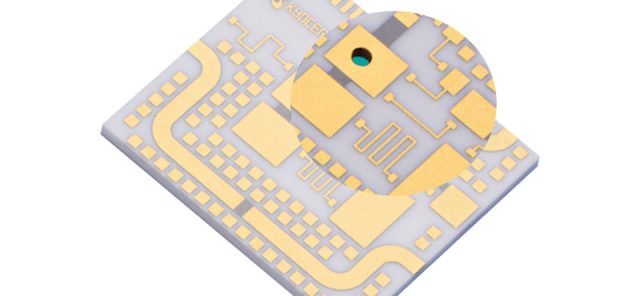

3. Thick-Film Ceramic PCB

Utilizing gold or silver-palladium pastes printed on ceramic substrates, this process achieves conductor thicknesses exceeding 10 μm after high-temperature firing. It allows direct integration of passive components such as resistors and capacitors while offering outstanding oxidation resistance and surface reliability.

Advantages of Ceramic PCBs

The unique combination of thermal, mechanical, and electrical advantages positions ceramic PCBs as a superior alternative to traditional substrates:

-

Exceptional Thermal Conductivity: Ceramic materials dissipate heat up to 100 times more efficiently than FR-4, ensuring system stability under extreme power loads.

-

Low Thermal Expansion: A CTE closely matched to silicon minimizes mechanical stress and solder fatigue.

-

Environmental Resistance: Naturally resistant to oxidation, moisture, and chemical corrosion.

-

Mechanical Durability: High rigidity and hardness provide superior vibration and shock resistance.

Electrical Stability: Low dielectric constant and strong insulation performance support high-frequency and RF applications.

Applications of Ceramic PCBs

Thanks to their thermal resilience and long-term stability, ceramic PCBs are utilized across multiple high-performance industries, including:

-

Power electronics (inverters, converters, voltage regulators)

-

RF and microwave communication modules

-

Automotive radar and LiDAR

-

Semiconductor packaging and hybrid microcircuits

-

Medical diagnostic and laser therapy equipment

These applications benefit from the consistent heat dissipation, signal stability, and structural endurance of KKPCB’s ceramic PCB platforms.

Why Choose Ceramic PCBs Over Traditional Boards

Compared to FR-4 or metal-clad alternatives, ceramic PCBs deliver unmatched reliability and precision. Their temperature tolerance up to 350°C, coupled with stable dielectric properties, enables engineers to design for higher power densities and greater system longevity.

Ceramic PCBs are not just an upgrade—they are the foundation of next-generation electronic design, balancing innovation with robust engineering performance.

Conclusion

At KKPCB, we are dedicated to advancing the frontier of electronic materials. Our high-precision ceramic PCB solutions combine superior heat management with mechanical resilience to meet the rigorous demands of modern technology.

Through our one-stop service platform—covering material selection, circuit layout, multilayer design, and final assembly—KKPCB ensures every board we produce meets the highest international standards for thermal, mechanical, and electrical performance.

As industries evolve toward higher power density and smaller form factors, ceramic PCBs will remain a cornerstone of advanced electronic innovation, enabling smarter, faster, and more reliable systems across the globe.