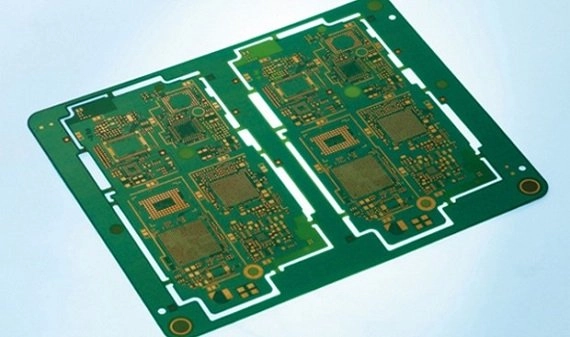

What Is a BT Epoxy PCB?

A BT Epoxy PCB is a high-performance printed circuit board manufactured using Bismaleimide Triazine (BT) resin-based epoxy material.

BT Epoxy PCB is widely used in IC substrate applications, semiconductor packaging, memory modules, and high-density electronic devices, where thermal stability, dimensional accuracy, and electrical performance are critical.

Compared with standard FR-4 PCB, BT Epoxy PCB offers:

-

Higher glass transition temperature (High Tg)

-

Lower moisture absorption

-

Better dimensional stability

-

Improved electrical performance

-

Excellent compatibility with semiconductor packaging

Because of these advantages, BT Epoxy PCB is commonly used as an IC substrate PCB.

Key Properties of BT Epoxy PCB

BT Epoxy PCB material provides several important characteristics:

-

High Tg (typically 180–200°C)

-

Low coefficient of thermal expansion (CTE)

-

Low dielectric constant

-

Low moisture absorption rate

-

Good chemical resistance

-

High mechanical strength

These properties make BT Epoxy PCB suitable for fine pitch and high density PCB designs.

BT Epoxy PCB vs FR-4 PCB

| Feature | BT Epoxy PCB | FR-4 PCB |

|---|---|---|

| Glass Transition Temperature | High | Moderate |

| Moisture Absorption | Low | Higher |

| Dimensional Stability | Excellent | Moderate |

| Application Level | Semiconductor / IC | General electronics |

For BGA, CSP, and IC packaging, BT Epoxy PCB performs significantly better than standard FR-4.

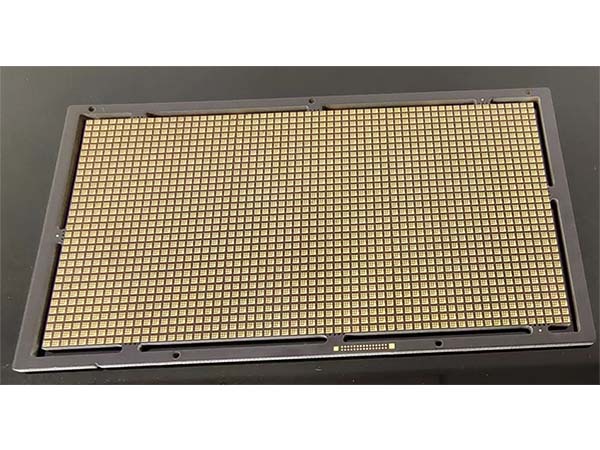

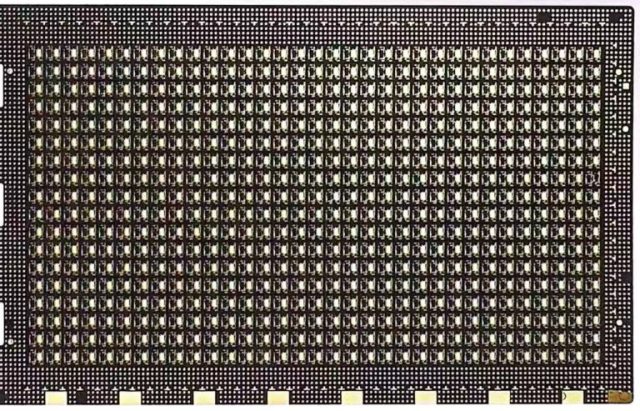

BT Epoxy PCB in Semiconductor Applications

BT Epoxy PCB is widely used in:

-

IC substrate PCB

-

BGA substrate PCB

-

CSP packaging PCB

-

Memory module PCB

-

Processor substrate

-

RF IC substrate

Because of its low CTE and excellent dimensional stability, BT Epoxy PCB ensures:

-

Stable solder joint reliability

-

Reduced thermal stress

-

Improved signal integrity

-

High yield in semiconductor assembly

BT Epoxy PCB for High Density Design

Modern semiconductor devices require:

-

Fine line and fine spacing

-

Microvia structures

-

High layer count

-

High precision alignment

BT Epoxy PCB supports:

-

HDI PCB technology

-

Laser microvia drilling

-

Multilayer substrate structures

-

High pin count routing

For high density PCB and fine pitch PCB applications, BT Epoxy PCB provides consistent performance.

Electrical Performance of BT Epoxy PCB

In high-speed and high-frequency designs, BT Epoxy PCB offers:

-

Stable dielectric constant

-

Lower signal loss compared to standard materials

-

Better impedance control capability

-

Improved signal integrity

BT Epoxy PCB is frequently used in:

-

High speed logic PCB

-

Memory test PCB

-

Mixed signal IC PCB

-

RF IC PCB

BT Epoxy PCB Manufacturing Capabilities

Professional BT Epoxy PCB manufacturers provide:

-

IC substrate PCB fabrication

-

HDI BT Epoxy PCB

-

Multilayer BT Epoxy PCB

-

High Tg PCB production

-

Fine pitch and fine line capability

-

Controlled impedance substrate PCB

Strict quality control ensures:

-

Dimensional accuracy

-

Reliable via integrity

-

Stable dielectric performance

-

Semiconductor-grade reliability

Applications of BT Epoxy PCB

BT Epoxy PCB is widely used in:

-

CPU and GPU substrates

-

DRAM and NAND memory modules

-

RF communication chips

-

Automotive semiconductor modules

-

Consumer electronics IC packaging

-

5G IC module PCB

For high precision semiconductor applications, BT Epoxy PCB ensures long-term stability and high production yield.

Choosing a Reliable BT Epoxy PCB Supplier

When selecting a BT Epoxy PCB supplier, consider:

-

Experience in IC substrate manufacturing

-

HDI and microvia capability

-

Fine line fabrication precision

-

Quality assurance systems

-

Semiconductor-grade process control

-

Fast prototype and volume production support

A professional BT Epoxy PCB manufacturer provides stable material sourcing, precise manufacturing control, and reliable long-term performance.