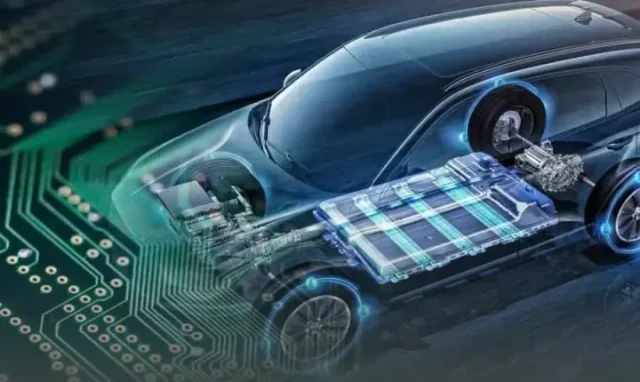

Automotive radar PCB manufacturing is a critical technology supporting modern Advanced Driver Assistance Systems (ADAS) and autonomous driving applications. Automotive radar systems rely on high-frequency and millimeter-wave signals, typically operating at 24GHz, 60GHz, and 77GHz, to detect objects, measure distance, and enable functions such as adaptive cruise control, collision avoidance, and blind-spot detection.

To ensure accurate signal transmission and long-term reliability, automotive radar PCBs require specialized materials, precise impedance control, and strict manufacturing processes that comply with automotive quality standards.

What Is an Automotive Radar PCB?

An automotive radar PCB is a high-frequency printed circuit board designed for radar sensors used in vehicles. These PCBs integrate RF transmission lines, antennas, power management circuits, and signal processing components within compact and robust layouts.

Due to the harsh automotive environment—temperature cycling, vibration, and humidity—automotive radar PCB manufacturing must meet higher reliability and durability requirements than standard electronic PCBs.

Key Requirements in Automotive Radar PCB Manufacturing

Low Loss and High Frequency Performance

Automotive radar systems operate at mmWave frequencies, where signal loss directly impacts detection accuracy. Low dielectric loss (low Df) materials are essential to minimize attenuation and ensure stable radar performance.

Precise Controlled Impedance

Accurate impedance control is critical in automotive radar PCB manufacturing to reduce signal reflection and phase distortion. Tight control of stack-up, trace geometry, and dielectric thickness is required.

Thermal and Mechanical Reliability

Radar PCBs must withstand wide temperature ranges and mechanical stress. High Tg materials and optimized thermal management improve long-term stability.

High Manufacturing Consistency

Automotive radar PCBs require excellent process repeatability to ensure consistent radar performance across mass production.

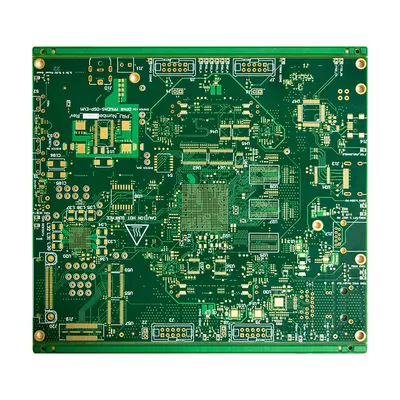

Materials Used in Automotive Radar PCB Manufacturing

Material selection is one of the most important factors in automotive radar PCB manufacturing.

Rogers and Low-Loss Laminates

Materials such as Rogers RO3003, RO4003C, RO4350B, and RT/duroid series are commonly used due to their stable dielectric properties at high frequencies.

Taconic High Frequency Materials

Taconic RF-35 and TLY series materials provide low loss and good thermal performance for radar sensor applications.

Hybrid PCB Stack-Ups

Many automotive radar PCBs use hybrid constructions combining low-loss RF materials with high-Tg FR-4 to balance performance and cost.

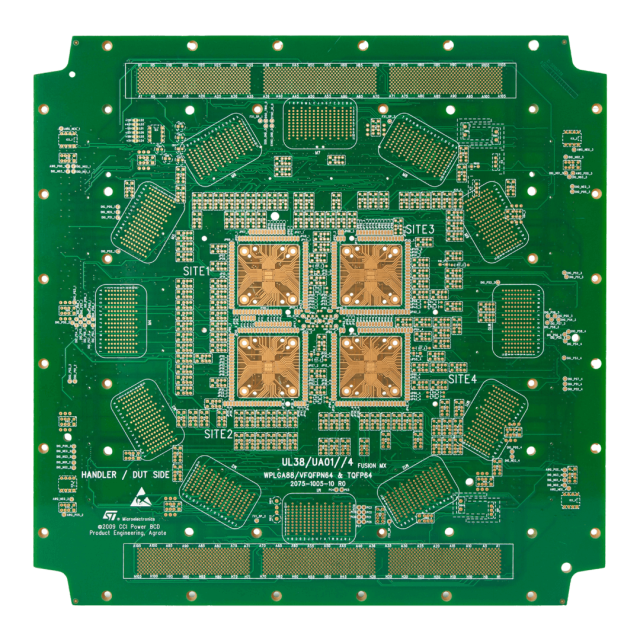

Manufacturing Capabilities for Automotive Radar PCBs

Professional automotive radar PCB manufacturing requires advanced fabrication technology, including:

-

Controlled impedance PCB processing

-

Precision multilayer lamination

-

Fine line and space etching

-

Laser drilling for microvias

-

RF-specific surface finishes such as ENIG or immersion silver

-

Impedance testing and electrical verification

Strict quality control ensures that each automotive radar PCB meets performance and reliability standards.

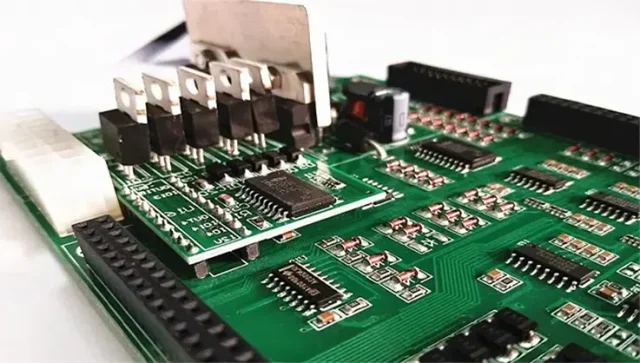

Design Challenges and Engineering Support

Automotive radar PCB design presents unique challenges:

-

Antenna integration and RF layout optimization

-

Minimizing signal loss and crosstalk

-

Via stub reduction and back-drilling

-

EMI shielding and grounding strategies

-

Mechanical reinforcement for automotive environments

An experienced automotive radar PCB manufacturer provides DFM and engineering support to improve first-pass design success.

Applications of Automotive Radar PCBs

Automotive radar PCBs are widely used in:

-

Adaptive cruise control (ACC)

-

Forward collision warning (FCW)

-

Blind spot detection (BSD)

-

Parking assistance systems

-

Autonomous driving sensor platforms

Reliable automotive radar PCB manufacturing is essential to ensure safety-critical system performance.

From Prototype to Mass Production

Automotive radar PCB manufacturing typically starts with prototype validation to verify RF performance, impedance accuracy, and thermal stability. Once validated, the same processes and materials are scaled to volume production, ensuring consistency and long-term reliability.

Working with a single supplier from prototype through mass production reduces risk and shortens development cycles.

Conclusion

Automotive radar PCB manufacturing plays a vital role in enabling advanced driver assistance and autonomous driving technologies. By combining low-loss high-frequency materials, precise impedance control, and automotive-grade manufacturing processes, professional PCB suppliers deliver reliable radar solutions that meet the most demanding industry requirements.

As vehicle safety and automation continue to evolve, choosing an experienced automotive radar PCB manufacturing partner becomes a key factor in product success.