Alumina PCBs: The Future of Reliable Ceramic Circuit Technology

In high-performance electronics, the choice of substrate material determines the efficiency, durability, and signal integrity of a circuit. Among modern materials, Alumina (Al₂O₃) has emerged as one of the most reliable and versatile solutions for printed circuit board (PCB) design. With its exceptional thermal conductivity, electrical insulation, and mechanical stability, Alumina enables engineers to build smarter, more durable, and more compact electronic systems.

At KKPCB, we specialize in manufacturing precision Alumina PCBs that meet the demands of today’s high-frequency, power, and LED-based industries—bridging the gap between performance and production efficiency.

What Is an Alumina PCB?

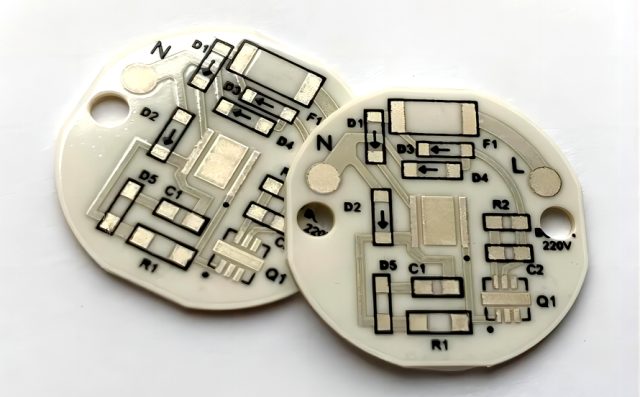

An Alumina PCB is a ceramic-based printed circuit board made from aluminum oxide rather than conventional FR-4 epoxy resin. This switch in substrate material significantly enhances thermal management and electrical insulation, especially in harsh environments.

Depending on the purity of the Alumina material, different grades such as 96%, 99%, and 99.6% are used in PCB fabrication—each with specific benefits for various thermal and mechanical requirements.

| Property | 96% Alumina | 99% Alumina |

|---|---|---|

| Max Operating Temp | 1400 °C | 1600 °C |

| Thermal Conductivity | 25 W/m·K | 31.4 W/m·K |

| Dielectric Constant | 9.4 | 10 |

| Compressive Strength | 3000 Kgf/cm² | 3500 Kgf/cm² |

| Water Absorption | 0% | 0% |

These outstanding characteristics make Alumina the substrate of choice for LED lighting, RF modules, and power control systems that operate under high thermal loads.

Advantages of Alumina PCBs

-

Superior Thermal Conductivity – Transfers heat efficiently, extending component lifespan.

-

Outstanding Electrical Insulation – Ensures signal clarity in high-frequency designs.

-

Exceptional Dimensional Stability – Maintains structural integrity under temperature shifts.

-

High Mechanical Strength – Provides durability in vibration or impact environments.

-

Chemical and Moisture Resistance – Enhances reliability in harsh or humid conditions.

-

Radiation and Wear Resistance – Ideal for aerospace, defense, and medical electronics.

-

Cost-Effective Manufacturing – Processes similarly to FR-4 with greater long-term value.

In short, Alumina PCBs merge the robustness of ceramics with the scalability of traditional PCB production, setting a new standard for high-performance electronics.

KKPCB’s Manufacturing Process and Design Precision

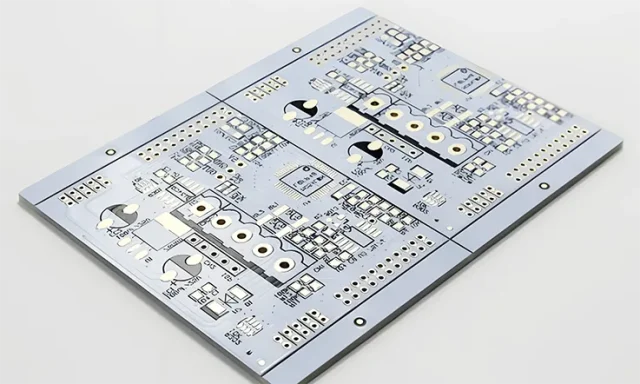

Producing high-quality Alumina PCBs requires mastery in ceramic processing, metallization, and fine-pattern circuit design. KKPCB applies strict process control at every stage:

-

Substrate Formation – High-purity Alumina powder is compressed, sintered above 1600 °C, and cooled for optimal density and stability.

-

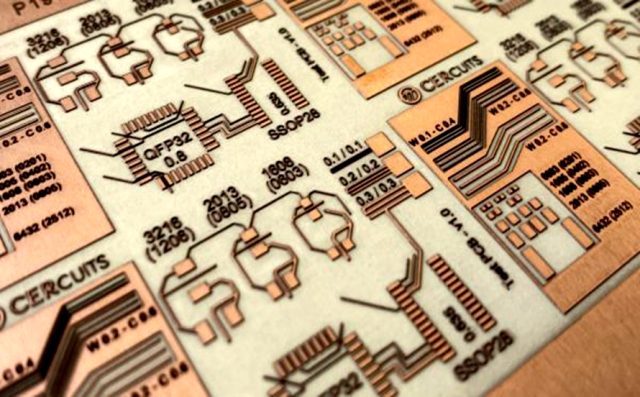

Metallization and Circuit Printing – Conductive layers using tungsten or molybdenum are screen-printed, etched, and plated with copper or nickel for durability.

-

Drilling, Plating, and Surface Finishing – Through-holes and vias are plated and finished to meet precise electrical specifications.

-

Testing and Inspection – Each board undergoes high-voltage, thermal shock, and dimensional accuracy testing to meet global reliability standards.

During design, engineers should consider factors like thermal expansion (CTE) matching, impedance control, and mechanical stress mitigation to maximize performance.

Applications of Alumina PCBs

-

LED Lighting Systems – High heat dissipation extends LED lifespan and brightness stability.

-

Automotive Electronics – Resists vibration, heat, and long-duty cycles.

-

RF & Microwave Systems – Supports high-frequency transmission with minimal signal loss.

-

Power Electronics – Ideal for MOSFETs, IGBTs, inverters, and high-power modules.

-

Aerospace and Industrial Control – Performs reliably in high-temperature, high-stress environments.

Conclusion: The Ceramic Foundation of the Future

As industries move toward higher power density, smarter devices, and sustainable systems, Alumina PCBs have become a cornerstone of modern electronic innovation.

Their combination of thermal efficiency, electrical stability, and mechanical resilience makes them indispensable for engineers designing the next generation of advanced hardware.

At KKPCB, we are committed to pushing the boundaries of ceramic PCB manufacturing—delivering precision, performance, and reliability for every application.

The future of PCB technology is ceramic. And Alumina stands at its heart.