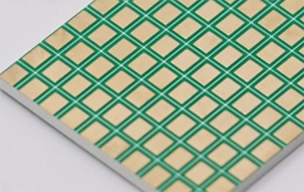

What Is Alumina PCB?

An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Alumina ceramic PCBs are widely used in high-power, high-temperature, and high-reliability electronic applications due to their excellent thermal conductivity, electrical insulation, and mechanical strength.

Compared with traditional FR-4 PCBs, Alumina PCBs provide superior heat dissipation, higher dielectric strength, and long-term stability, making them ideal for harsh operating environments.

Key Material Properties of Alumina PCB

Alumina ceramic material offers outstanding physical and electrical characteristics:

-

High thermal conductivity

Typically 20–30 W/m·K, much higher than FR-4. -

Excellent electrical insulation

High dielectric strength ensures safe operation. -

Low dielectric loss

Suitable for high-frequency and power applications. -

High mechanical strength and hardness

Resistant to deformation and wear. -

High temperature resistance

Stable performance in extreme environments.

These properties make Alumina PCB a preferred ceramic substrate.

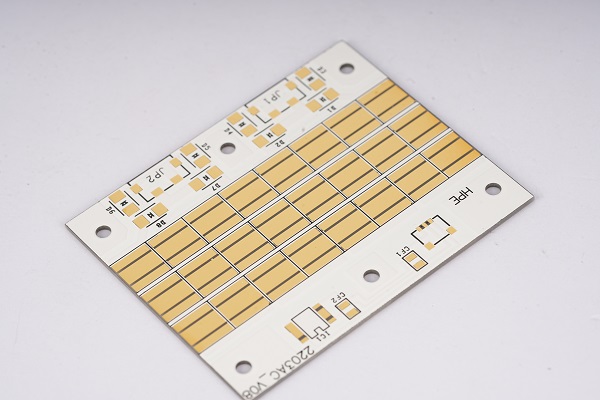

Alumina PCB Manufacturing Processes

Manufacturing an Alumina PCB involves specialized ceramic processes:

-

Thick film or thin film metallization

-

Direct Bonded Copper (DBC)

-

Active Metal Brazing (AMB)

-

Laser or precision mechanical drilling

-

High-temperature sintering

These processes ensure reliable copper adhesion and excellent thermal performance.

Advantages of Alumina PCB

Using an Alumina PCB provides multiple benefits:

-

Excellent thermal management for high-power devices

-

Superior electrical insulation and safety

-

High reliability and long service life

-

Stable performance at high temperatures

-

Compact design for high-density power modules

Alumina PCBs are widely adopted in power and industrial electronics.

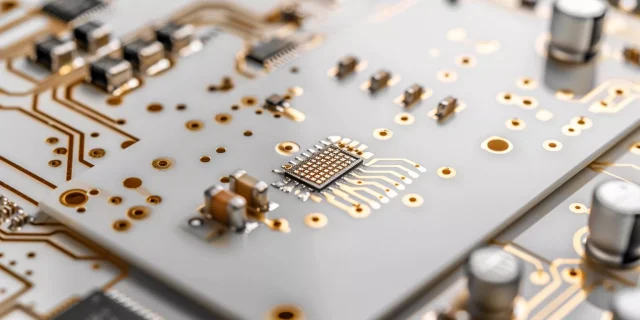

Applications of Alumina PCB

Alumina PCBs are commonly used in:

-

Power modules and power supplies

-

LED lighting and laser drivers

-

Automotive power electronics

-

Industrial control systems

-

Semiconductor packaging and test boards

-

High-reliability aerospace and defense electronics

They are ideal for applications requiring thermal stability and electrical isolation.

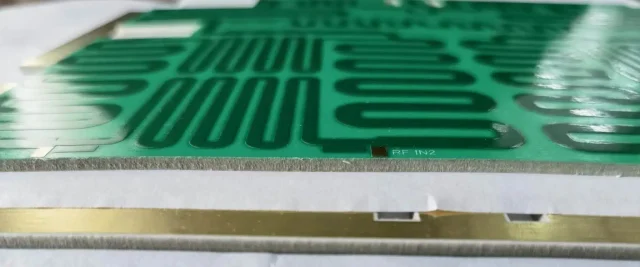

Alumina PCB vs FR-4 PCB

Compared with FR-4 PCBs, Alumina PCBs offer:

-

Much higher thermal conductivity

-

Better high-temperature resistance

-

Superior electrical insulation

-

Longer lifespan in harsh conditions

For high-power and high-reliability designs, Alumina PCB significantly outperforms FR-4.

Conclusion

An Alumina PCB is a robust and reliable solution for high-power, high-temperature, and high-reliability applications. With excellent thermal conductivity, electrical insulation, and mechanical strength, Alumina ceramic PCBs support advanced electronic systems where conventional materials fall short.

Selecting an experienced Alumina PCB manufacturer ensures optimized metallization, strong copper adhesion, and consistent production quality.