Advanced High-Frequency PCB Solutions with Rogers RT/duroid® 5880

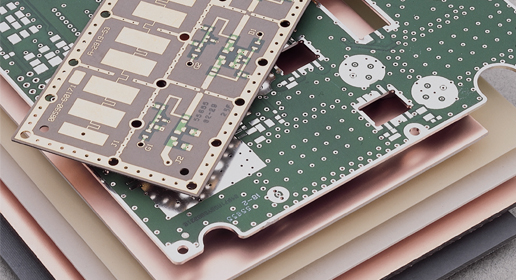

In high-frequency circuit design, material selection defines performance. Rogers RT/duroid 5880, known for its exceptional electrical stability and low signal loss, has become the industry standard for RF and microwave applications. At KKPCB, we specialize in manufacturing high-frequency PCB that fully leverage the advantages of this premium material to deliver outstanding reliability and signal integrity.

Low Dielectric Constant and Ultra-Low Loss

RT/duroid 5880 is a homogeneous PTFE composite reinforced with glass microfibers. It features a dielectric constant (Dk) of 2.20 ± 0.02 and an extremely low I said.

These characteristics ensure minimal signal attenuation across wide frequency bands, making it ideal for applications such as 5G communication, satellite systems, radar modules, and RF amplifiers.

Compared to conventional FR-4 materials, Duroid 5880 enables superior signal purity and phase stability, which are critical in GHz-level transmission.

Thermal Stability and Environmental Reliability

High-frequency devices often operate under high power and fluctuating temperatures. RT/duroid 5880 offers excellent thermal conductivity (0.2 W/m·K) and a low coefficient of thermal expansion (16 ppm/°C), ensurin.

This thermal consistency prevents signal drift and layer separation, providing long-term reliability for demanding environments such as aerospace, defense, and medical electronics.

Precision Impedance Control and Manufacturability

For GHz-level design, impedance consistency is essential to maintaining signal integrity. The uniform structure of Duroid 5880 allows for precise impedance control, giving engineers more flexibility in high-speed and RF design.

In manufacturing, the material performs well in laser drilling, fine-line etching, and multilayer lamination.

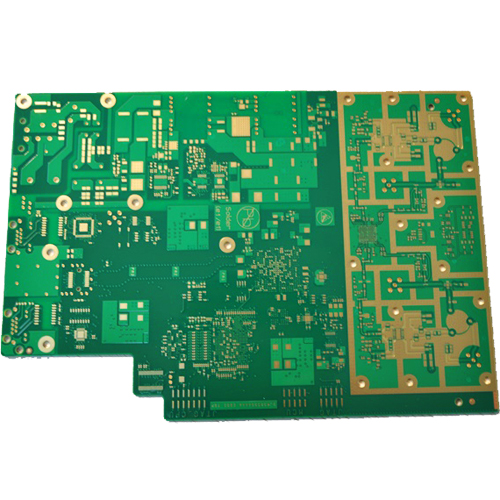

KKPCB advanced process control ensures microstrip and coplanar waveguide structures are fabricated to micron-level precision, supporting reliable mass production of 5G base stations, millimeter-wave radar, and RF modules.

Performance Comparison: RT/duroid 5880 vs. Rogers 4000 Series

| Parameter | RT/duroid 5880 | Rogers 4000 Series |

| Dielectric Constant (Dk) | 2.20 ± 0.02 | 3.38–3.66 |

| Dissipation Factor (Df) | 0.0004 | 0.0027 |

| Thermal Stability | Excellent | Very Strong |

| Typical Applications | RF/Microwave, Satellite, Radar | Power Circuits, Base Stations |

RT/duroid 5880 offers unmatched electrical performance for high-frequency and precision RF systems, while the 4000 series is more suited for high-power and mechanically robust applications.

At KKPCB, we help clients balance cost, dielectric performance, and thermal management to select the optimal material for each project.

Cost and Performance Balance

While Duroid 5880 carries a higher unit price than conventional materials, its long-term ROI is significantly superior. The enhanced signal efficiency, reduced rework rate, and extended service life lower the total system cost. For high-frequency products, performance and reliability far outweigh the material premium.

KKPCB Manufacturing Expertise

KKPCB has developed specialized high-frequency PCB processes to handle PTFE-based laminates like RT/duroid 5880. Our production includes automated optical inspection (AOI), impedance validation, and thermal cycling tests to ensure every board meets stringent reliability standards.

Our Duroid-based PCBs are widely used in 5G base stations, satellite communication systems, automotive radar, and RF testing equipment worldwide.

The Future of Advanced PCB Technologies

As millimeter-wave, satellite internet, and 6G technologies continue to evolve, the demand for ultra-low-loss materials will only increase.

Rogers RT/duroid 5880 is not only the foundation of today’s high-frequency circuits—it is also the cornerstone for next-generation communication systems.

With deep expertise in high-frequency PCB fabrication, KKPCB continues to deliver integrated solutions from material selection and stack-up design to mass production, enabling high-performance electronics to operate with unmatched stability at ever-higher frequencies.