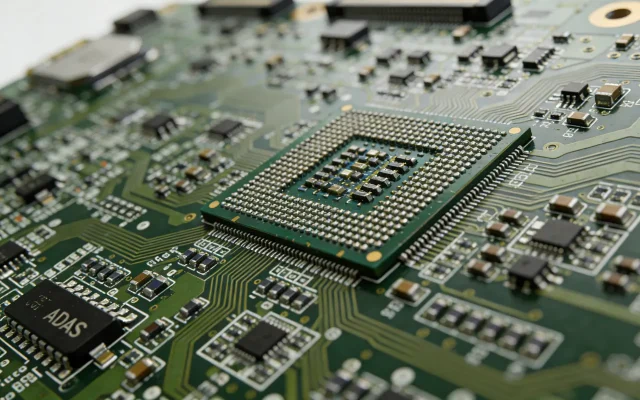

What Is an ADAS PCB?

An ADAS PCB is a specialized automotive PCB used in Advanced Driver Assistance Systems, such as radar, camera, LiDAR, and sensor fusion modules. These systems require high-speed data transmission, high-frequency signal processing, and exceptional reliability under demanding automotive conditions.

ADAS PCBs form the core platform that connects sensors, processors, and power management circuits in modern vehicles.

Technical Requirements of ADAS PCB

ADAS systems impose strict technical requirements on PCB design and manufacturing:

-

High-speed signal integrity for data processing

-

High-frequency performance for radar and sensor modules

-

Precise impedance controlled PCB design

-

Excellent thermal management

-

High reliability under vibration and temperature cycling

Meeting these requirements is critical for vehicle safety and system stability.

Material Selection for ADAS PCB

Material choice plays a crucial role in ADAS PCB performance. Commonly used materials include:

-

High-speed laminates (e.g. Megtron 6 / Megtron 7)

-

Low-loss RF materials (RO4350B, RF-35)

-

Hybrid PCB materials for mixed-signal designs

-

High-Tg FR-4 for control and power layers

Low-loss and stable materials ensure consistent performance across wide temperature ranges.

Impedance Control and Stack-Up Design

ADAS PCBs often require strict impedance controlled PCB structures to support high-speed and high-frequency signals:

-

Controlled impedance transmission lines

-

Optimized multilayer stack-ups

-

Minimized signal skew and crosstalk

-

Careful via design for high-frequency transitions

Accurate impedance control ensures reliable data transmission in safety-critical systems.

Manufacturing and Reliability Requirements

Manufacturing an ADAS PCB demands automotive-grade quality control:

-

Tight process tolerance and trace accuracy

-

High-precision multilayer alignment

-

Advanced thermal and mechanical reliability testing

-

Compliance with automotive quality standards

-

Long-term reliability validation

Only experienced automotive PCB suppliers can meet these standards.

Applications of ADAS PCB

ADAS PCBs are widely used in:

-

Automotive radar modules

-

Camera and vision processing units

-

LiDAR and sensor fusion systems

-

Electronic control units (ECUs)

-

Autonomous driving platforms

They enable safer and smarter vehicle operation.

Conclusion

An ADAS PCB is a critical component in modern vehicles, requiring high-speed performance, high-frequency capability, and exceptional reliability. Advanced materials, precise impedance control, and automotive-grade manufacturing processes are essential for successful ADAS PCB production.

Selecting a professional ADAS PCB manufacturer ensures compliance, performance stability, and long-term reliability from prototype development to mass production.