Introduction

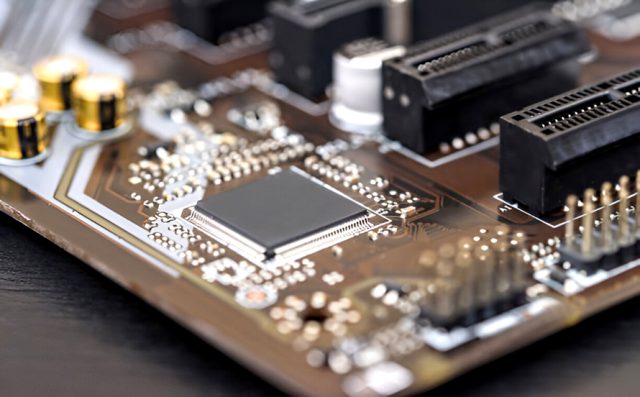

With the rapid advancement of modern technology, high-frequency electronic systems such as RF, microwave, and radar equipment are increasingly prevalent. At the core of these systems lies the Printed Circuit Board (PCB) — the foundation upon which signal integrity and overall device performance depend. Among the materials used for PCB fabrication, Teflon (PTFE) stands out due to its exceptional electrical, thermal, and mechanical properties, making it the material of choice for high-frequency applications.

What Are Teflon (PTFE) PCBs?

Teflon, scientifically known as Polytetrafluoroethylene (PTFE), is a polymer renowned for its excellent dielectric performance and chemical stability. With a low dielectric constant (Dk) and minimal loss tangent (Df), Teflon enables efficient signal transmission with minimal distortion, making it ideal for RF and microwave circuits.

Teflon-based PCBs are specifically designed to minimize signal loss and ensure stable electrical characteristics — key requirements for devices such as communication systems, radar modules, satellites, and aerospace electronics.

Key Characteristics of Teflon PCBs

-

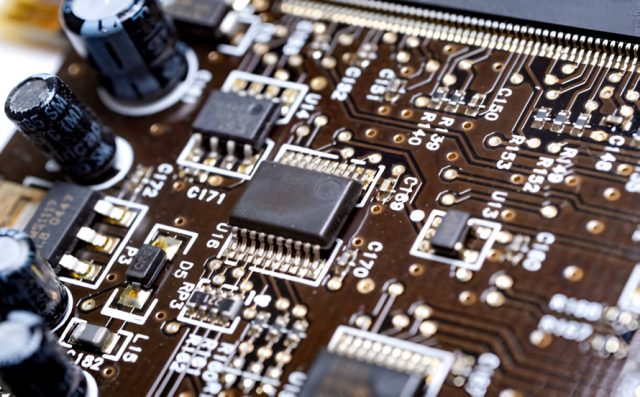

Low Dielectric Constant (Dk 2.1–2.5)

A lower dielectric constant ensures faster signal propagation and improved signal integrity, outperforming standard FR4 boards (Dk ≈ 4.5). -

Low Loss Tangent (Df ≤ 0.001)

The low loss tangent reduces signal attenuation, enabling high-frequency signals to travel over longer distances with minimal distortion — a critical advantage in RF and microwave designs. -

High Thermal Stability (Up to 327°C)

Teflon PCBs maintain dimensional and electrical stability under extreme temperatures, ensuring consistent performance during soldering and long-term operation. -

Chemical Inertness and Corrosion Resistance

PTFE’s resistance to acids, bases, and solvents allows it to perform reliably in harsh environments such as aerospace, military, and industrial settings. -

Excellent Electrical Insulation

High insulation properties reduce electromagnetic interference (EMI) and crosstalk between signals, ensuring superior circuit clarity. - Low Coefficient of Thermal Expansion (CTE)

Minimal dimensional change under thermal stress preserves precise circuit geometry — essential for multilayer and high-frequency PCB assemblies.

Considerations in Teflon PCB Manufacturing

-

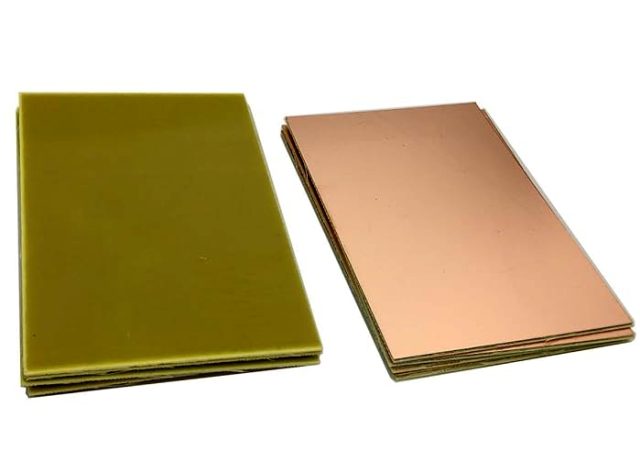

Material Handling

Due to Teflon’s softness and flexibility, precision cutting, drilling, and lamination are required to prevent mechanical deformation during processing. -

Controlled Impedance Design

Achieving accurate impedance control demands precise management of trace width, spacing, and layer thickness — often supported by advanced simulation software. -

Surface Finishing

Surface finishes like ENIG (Electroless Nickel Immersion Gold), Immersion Silver, or Immersion Tin enhance solderability, conductivity, and oxidation resistance. -

Manufacturing Tolerances

Teflon’s non-stick nature makes it challenging to maintain tight tolerances. Experienced PCB manufacturers must employ specialized methods to ensure accuracy and reliability.

Advantages of Teflon PCBs in High-Frequency Applications

-

Superior Signal Integrity

Low Dk and Df values minimize signal loss and distortion, ensuring consistent, accurate transmission for wireless, radar, and satellite systems. -

High-Frequency Performance

- Designed for operation beyond 1 GHz, Teflon PCBs deliver stable performance in RF amplifiers, mixers, filters, and oscillators.

-

Enhanced Thermal Management

Excellent heat resistance prevents component degradation and ensures long-term reliability in demanding thermal environments. -

Durability and Longevity

Exceptional environmental resistance results in longer service life and reduced maintenance costs.

Lightweight Construction

Teflon’s low density makes it ideal for aerospace and portable electronic systems where weight reduction is critical.

Conclusion

While Teflon PCBs are more expensive than conventional FR4 boards, their superior signal performance, reliability, and durability make them the optimal choice for high-frequency and mission-critical applications. As the demand for faster, more efficient communication systems continues to grow, Teflon PCBs will remain an essential enabler of next-generation technology.