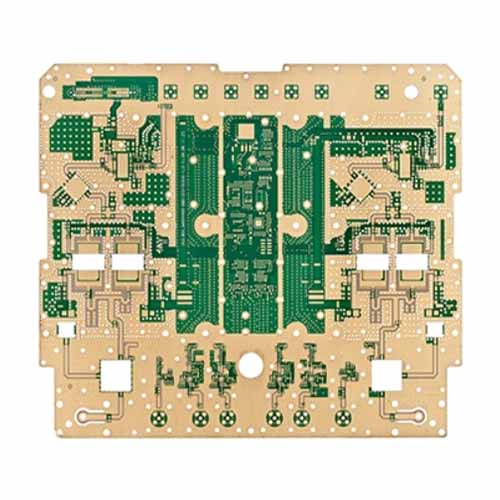

Unleashing Thermal Power: Aluminum Nitride (AlN) PCB for Next-Generation Electronics

Introduction

At KKPCB, we understand that advanced electronics demand equally advanced substrates. Aluminum Nitride (AlN) PCB represents the forefront of ceramic circuit board technology — a material engineered to deliver unmatched heat dissipation, electrical insulation, and mechanical stability.

Unlike traditional FR-4 laminates, AlN PCBs use aluminum nitride ceramic as the dielectric core. This enables the direct deposition of copper circuits through thin-film, thick-film, or Direct Bond Copper (DBC) methods, creating a thermally robust and electrically reliable platform for high-performance systems.

Its exceptional thermal conductivity (170–200 W/m·K) and near-perfect match to silicon’s thermal expansion coefficient make AlN the ideal foundation for high-power, high-frequency, and high-temperature designs. Although more costly than standard materials, the investment in AlN translates into superior reliability and longer product life in mission-critical applications such as power conversion, aerospace, and LED systems.

Why Choose Aluminum Nitride PCB

Aluminum Nitride PCBs offer several key advantages that make them the preferred choice for demanding electronic systems:

-

Exceptional Thermal Conductivity

AlN substrates rapidly dissipate heat, preventing thermal accumulation that can degrade performance or cause premature failure. -

High-Frequency Stability

The low dielectric loss of AlN ensures minimal signal attenuation, making it ideal for RF, microwave, and millimeter-wave applications. -

Outstanding Electrical Insulation

High dielectric strength and resistivity safeguard signal integrity and component isolation, even under extreme voltage conditions. -

Mechanical Robustness

AlN ceramics provide superior mechanical strength, resisting warpage and maintaining dimensional stability in high-stress environments. -

Thermal Compatibility with Silicon

Matching the thermal expansion of semiconductor materials minimizes mechanical stress, improving device lifespan and connection integrity. -

High-Power & High-Temperature Reliability

Perfect for power amplifiers, LED drivers, and laser modules — AlN boards maintain stability beyond 1000°C. -

Long-Term Durability

Corrosion resistance and low moisture absorption ensure longevity even in harsh conditions.

These properties collectively make AlN PCBs the cornerstone for aerospace, automotive, medical, and power electronics, where precision and reliability define success.

Applications of AlN PCB

-

Power converters and inverters

-

Electric vehicle battery management and charging systems

-

High-brightness LED modules

-

RF amplifiers, filters, and antennas

-

Satellite and space electronics

-

Medical lasers and imaging systems

-

Aerospace avionics

-

High-temperature and radiation sensors

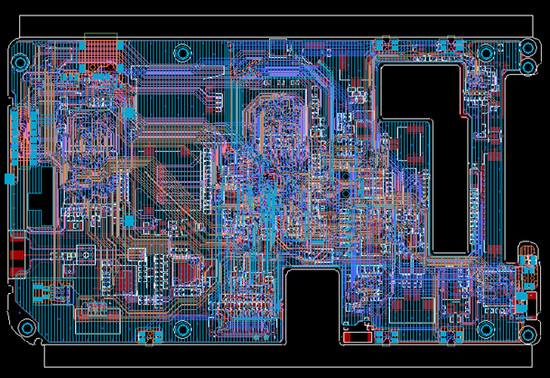

Design Considerations for AlN PCB

To unlock AlN’s full potential, designers must account for its thermal and mechanical behavior.

Key recommendations include:

-

Maintain trace thickness ≥10 mils for reliable current handling.

-

Ensure 8–10 mils spacing between conductors for insulation integrity.

-

Use gold-plated pads for wire bonding and corrosion protection.

-

Apply thermal vias under power components to maximize heat spreading.

-

Design with matched CTE components to prevent mechanical stress.

-

Incorporate ground planes for enhanced high-frequency signal stability.

-

Use precision tooling to prevent substrate damage during drilling or routing.

Manufacturing Process of AlN PCB

-

Substrate Formation – AlN powder undergoes cold isostatic pressing and high-temperature sintering (>1800°C) to achieve full ceramic density.

-

Metallization – Conductive traces are formed using tungsten, molybdenum, or copper via thick/thin film or DBC technology.

-

Multilayer Integration – Layers are laminated with conductive vias for complex circuit architecture.

-

Hermetic Sealing – Components can be enclosed using glass, epoxy, or braze for enhanced reliability in aerospace or defense-grade systems.

These manufacturing steps combine precision engineering with material science — resulting in boards that deliver both electrical precision and thermal endurance.

AlN vs. Alumina vs. FR-4: Performance Comparison

| Parameter | Aluminum Nitride | Alumina | FR-4 |

|---|---|---|---|

| Thermal Conductivity | 170–200 W/m·K | 24–30 W/m·K | 0.25–0.5 W/m·K |

| Dielectric Constant | 8.8 | 9.2–10 | 4.2–4.6 |

| Temperature Resistance | 1000–1500°C | 1000–1200°C | 130–170°C |

| Coefficient of Thermal Expansion | 4.0 ppm/K | 6.5–7 ppm/K | 17–20 ppm/K |

| Flexural Strength | 330 MPa | 300 MPa | 180 MPa |

AlN clearly outperforms both Alumina and FR-4 in thermal performance, temperature tolerance, and mechanical stability, positioning it as the ideal substrate for next-generation power and RF electronics.

Conclusion

At KKPCB, we don’t just manufacture boards — we engineer thermal precision. Our expertise in Aluminum Nitride PCB design and production enables us to deliver reliable, high-performance ceramic solutions that thrive under extreme thermal and electrical conditions.

From concept to mass production, KKPCB provides one-stop PCB & PCBA services that ensure your products maintain the highest standards of reliability, conductivity, and design excellence.

When your application demands performance beyond the limits of FR-4, AlN technology is the answer — and KKPCB is the partner to make it real.