A 5G mmWave PCB is a critical enabling technology for millimeter wave (mmWave) communication systems operating at extremely high frequencies such as 24 GHz, 28 GHz, 39 GHz, and beyond. As global 5G networks expand, mmWave technology is essential for achieving ultra-high data rates, low latency, and increased network capacity.

Designing and manufacturing reliable 5G mmWave PCBs requires advanced materials, precise impedance control, and specialized RF manufacturing expertise.

What Is a 5G mmWave PCB?

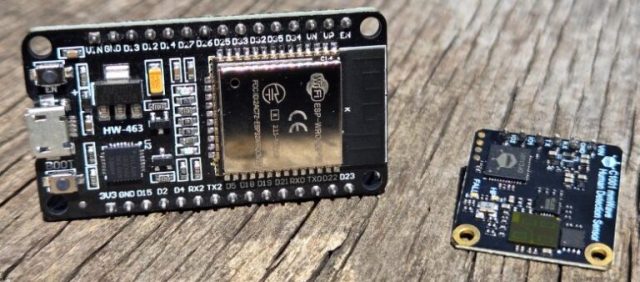

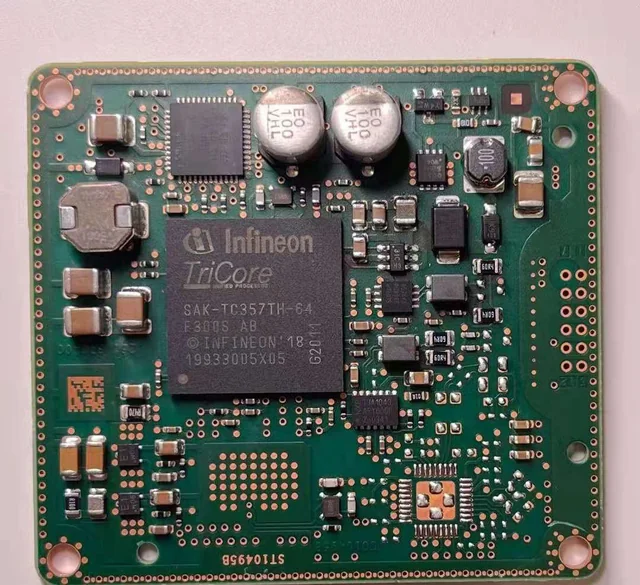

A 5G mmWave PCB is a high-frequency printed circuit board designed to support millimeter wave signal transmission in 5G communication systems. These PCBs integrate RF transmission lines, antennas, power management, and high-speed digital interfaces within compact form factors.

Due to the extreme sensitivity of mmWave signals to loss and impedance variation, 5G mmWave PCBs demand much tighter electrical and mechanical tolerances than conventional RF PCBs.

Key Requirements for 5G mmWave PCBs

Ultra-Low Signal Loss

At mmWave frequencies, even small dielectric or conductor losses significantly impact performance. 5G mmWave PCBs must use ultra-low Df materials to minimize attenuation.

Precise Controlled Impedance

Accurate impedance control is essential to reduce reflection, phase error, and signal distortion. Tight control of stack-up, trace geometry, and dielectric thickness is required.

Excellent Signal Integrity

Short interconnect paths, optimized via structures, and low-roughness copper improve signal integrity at high frequencies.

Thermal and Mechanical Stability

5G mmWave PCBs must maintain stable performance under temperature variation and mechanical stress, especially in outdoor and base station applications.

Materials Used in 5G mmWave PCB Manufacturing

Material selection is one of the most critical aspects of 5G mmWave PCB manufacturing.

Common materials include:

-

Rogers RO3003, RO4003C, RO4350B

-

RT/duroid 5880 and 6010

-

Taconic RF-35, TLY-5

-

Hybrid stack-ups combining low-loss RF materials with high-Tg FR-4

These materials provide stable dielectric properties and minimal loss at mmWave frequencies.

Manufacturing Capabilities for 5G mmWave PCBs

Producing high-quality 5G mmWave PCBs requires advanced manufacturing technology:

-

Controlled impedance PCB processing

-

Precision multilayer and hybrid lamination

-

Fine line and space etching for RF accuracy

-

Laser drilling for microvias and RF vias

-

RF-optimized surface finishes such as ENIG or immersion silver

-

Impedance and electrical performance testing

Strict process control ensures consistent mmWave performance from prototype to mass production.

Design Challenges and Engineering Support

5G mmWave PCB design presents unique challenges:

-

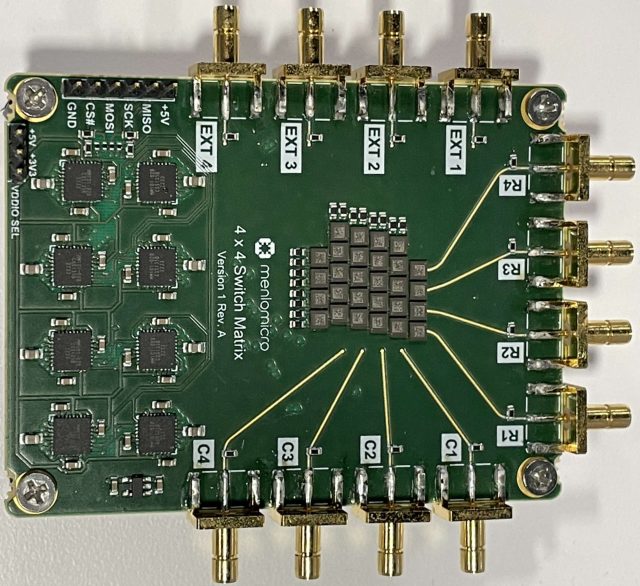

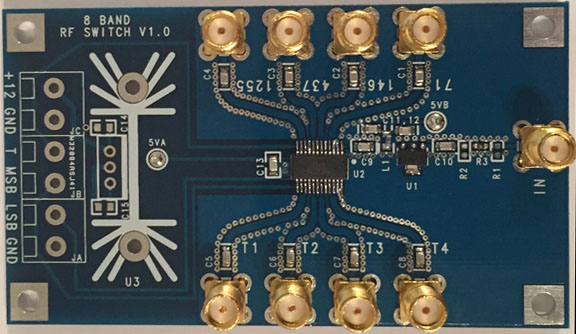

Antenna and RF front-end integration

-

Minimizing via stubs and discontinuities

-

Signal isolation and EMI control

-

High-density routing in compact modules

-

Consistency across high-volume production

Experienced PCB manufacturers provide DFM, signal integrity analysis, and RF engineering support to improve first-pass success.

Applications of 5G mmWave PCBs

5G mmWave PCBs are widely used in:

-

5G base stations and small cells

-

5G antenna arrays and beamforming modules

-

mmWave transceiver modules

-

Fixed wireless access (FWA) systems

-

5G test and measurement equipment

In these applications, PCB performance directly affects network speed, coverage, and reliability.

From Prototype to Mass Production

5G mmWave PCB projects typically begin with prototype validation to verify RF performance, impedance accuracy, and antenna efficiency. Once validated, designs are scaled to volume production using consistent materials and tightly controlled manufacturing processes.

Working with an experienced 5G mmWave PCB supplier reduces development risk and accelerates time-to-market.

Conclusion

A 5G mmWave PCB is a foundational component of next-generation wireless communication systems. By combining ultra-low loss materials, precise impedance control, and advanced manufacturing processes, professional PCB suppliers deliver reliable mmWave solutions that meet the demanding requirements of 5G networks.

As 5G technology continues to evolve, choosing an experienced 5G mmWave PCB manufacturer is essential for achieving high performance, scalability, and long-term reliability.