What Is a Low Dissipation Factor PCB?

A Low Dissipation Factor PCB is a printed circuit board manufactured with dielectric materials that exhibit a low dissipation factor (Df), also known as loss tangent. The dissipation factor measures how much signal energy is lost as heat when electromagnetic waves propagate through the PCB substrate.

Lower Df values result in lower signal attenuation, making Low Df PCBs essential for high-speed digital and high-frequency RF designs.

Why Low Dissipation Factor Matters

In modern electronics, increasing data rates and operating frequencies demand minimal signal loss. A Low Dissipation Factor PCB offers:

-

Reduced dielectric loss

-

Improved signal integrity

-

Lower insertion loss

-

Cleaner eye diagrams

-

Higher system efficiency

-

Better thermal performance at high frequencies

These advantages are critical for GHz-level and multi-gigabit applications.

Typical Dissipation Factor Values

| PCB Material | Dissipation Factor (Df) |

|---|---|

| Standard FR-4 | 0.018 – 0.025 |

| High Tg FR-4 | 0.012 – 0.018 |

| Low Df Materials | 0.002 – 0.008 |

| RF / Microwave Laminates | ≤ 0.004 |

A lower Df directly translates into better high-frequency performance.

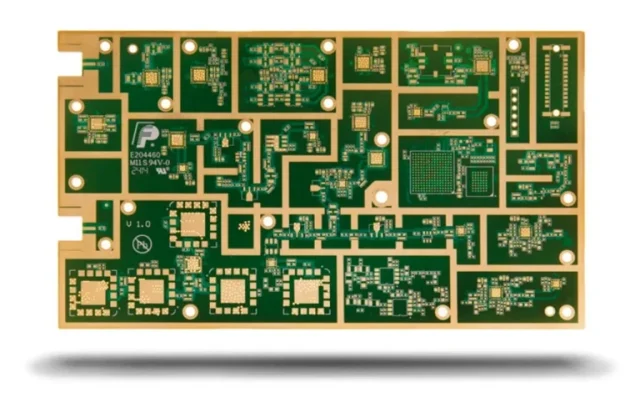

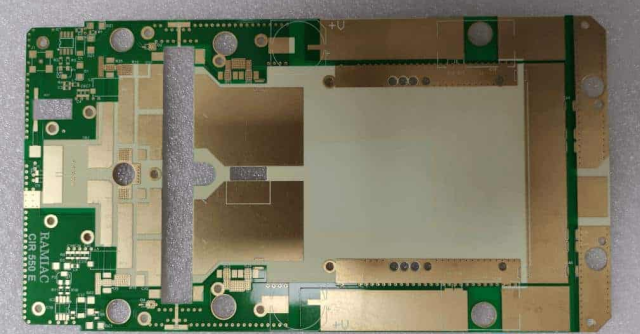

Low Dissipation Factor PCB Materials

Common materials used for Low Df PCB fabrication include:

-

Rogers RO4350B / RO4835

-

Rogers RO5880 (PTFE)

-

Taconic RF-35 / TLY-5

-

Megtron 6 / Megtron 7

-

Isola I-Speed and Tachyon

-

Hybrid PCB materials (RF + FR-4)

Material choice depends on frequency, signal speed, and cost considerations.

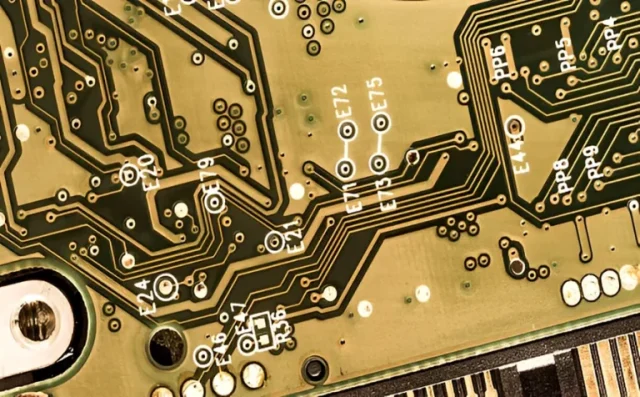

Design Considerations for Low Df PCB

Key design factors for a Low Dissipation Factor PCB include:

-

Controlled impedance design

-

Trace geometry optimization

-

High-quality dielectric thickness control

-

Surface roughness minimization

-

Proper ground referencing

-

Short, well-matched signal paths

Close collaboration between design and fabrication teams ensures optimal performance.

Manufacturing Requirements

Producing a Low Dissipation Factor PCB requires:

-

Precise lamination control

-

Tight impedance tolerance

-

Advanced drilling and plating

-

Low-roughness copper foil selection

-

Strict process control and testing

Experienced manufacturers can maintain consistency from prototype to mass production.

Applications of Low Dissipation Factor PCB

Low Dissipation Factor PCBs are widely used in:

-

High-speed digital systems

-

RF and microwave circuits

-

5G and mmWave modules

-

High-frequency sensor PCBs

-

ADAS and automotive radar

-

Satellite and aerospace electronics

-

ATE and semiconductor test boards

Conclusion

A Low Dissipation Factor PCB is essential for high-frequency and high-speed electronic systems where signal integrity is critical. By selecting low-loss materials, optimizing design, and applying advanced manufacturing processes, Low Df PCBs deliver reliable, high-performance signal transmission.

Choosing an experienced Low Dissipation Factor PCB manufacturer ensures consistent electrical performance, tight impedance control, and long-term reliability.