What Is an RF Transceiver PCB?

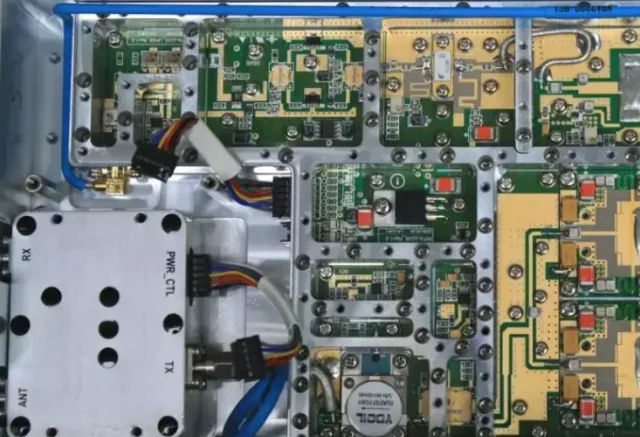

An RF Transceiver PCB is a specialized printed circuit board used in radio frequency transmission and reception systems. It integrates RF transmit (TX) and receive (RX) circuits on the same board, requiring precise control of signal integrity, impedance, and electromagnetic performance.

RF transceiver PCBs are critical in modern wireless communication systems where stable, low-loss RF performance is essential.

Key Requirements for RF Transceiver PCB

An RF transceiver PCB must meet strict electrical and mechanical requirements:

-

Controlled impedance for RF signal paths

-

Low insertion loss and return loss

-

Excellent isolation between TX and RX circuits

-

Stable dielectric properties across frequency

-

Low noise and minimal signal distortion

-

High reliability under thermal and environmental stress

These requirements directly impact system performance.

Materials for RF Transceiver PCB

Choosing the right material is critical for RF transceiver PCB design:

-

Low loss RF laminates (RO4350B, RO4835, RF-35, Taconic)

-

High-speed materials such as Megtron 7 for digital-RF integration

-

Hybrid PCB materials combining RF and FR-4 layers

-

Ceramic substrates (Alumina PCB) for high stability RF modules

Material selection depends on frequency range, power level, and thermal requirements.

Design Considerations for RF Transceiver PCB

RF transceiver PCB design requires advanced expertise:

-

Precise impedance control and stack-up design

-

Careful RF trace routing and grounding strategy

-

Isolation and shielding between RF sections

-

Minimization of parasitic effects

-

Thermal management for active RF components

-

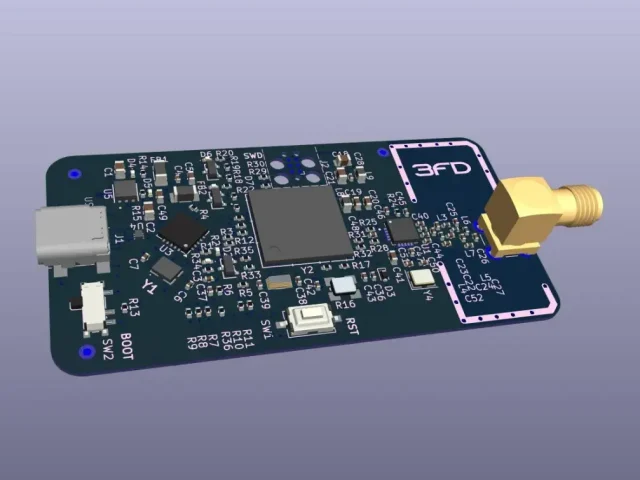

HDI structures for compact RF modules

Simulation and RF layout best practices are essential.

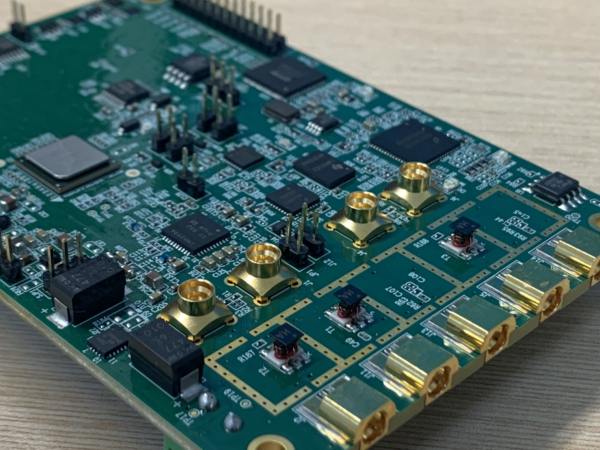

Manufacturing Challenges of RF Transceiver PCB

Manufacturing RF transceiver PCBs involves:

-

Tight control of dielectric thickness and copper geometry

-

Precision etching and lamination

-

Accurate drilling and via placement

-

Reliable surface finishes suitable for RF performance

-

Comprehensive RF and electrical testing

Consistency in manufacturing directly affects RF performance.

Applications of RF Transceiver PCB

RF transceiver PCBs are widely used in:

-

Wireless communication systems

-

5G and mmWave modules

-

Satellite communication equipment

-

IoT and RF sensor devices

-

Radar and navigation systems

-

RF test and measurement equipment

They form the backbone of RF-enabled electronics.

Conclusion

An RF Transceiver PCB is a key enabler for high-performance wireless systems, combining low loss materials, controlled impedance, and precision manufacturing. Proper design and fabrication ensure reliable RF signal transmission and reception across a wide frequency range.

Working with an experienced RF transceiver PCB manufacturer ensures optimized material selection, stable RF performance, and consistent quality from prototype to production.