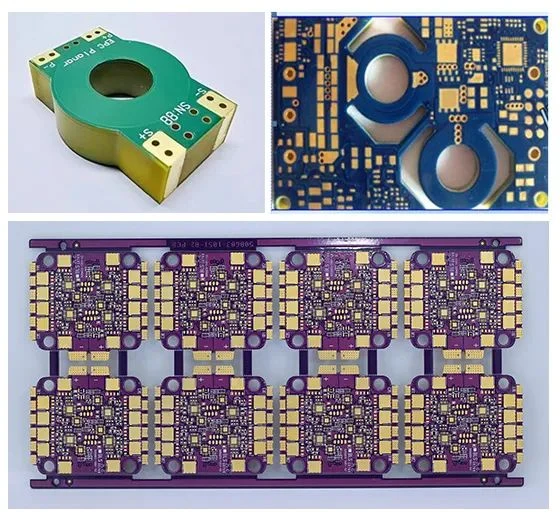

What Is a Heavy Copper PCB?

A Heavy Copper PCB is a printed circuit board manufactured with thick copper layers, typically ranging from 3 oz to over 20 oz per square foot, to support high current, high power, and enhanced thermal performance.

Compared with standard PCBs, heavy copper PCBs provide lower resistance, better heat dissipation, and higher mechanical strength, making them ideal for demanding power applications.

Key Advantages of Heavy Copper PCB

Using a Heavy Copper PCB offers several critical advantages:

-

High current carrying capacity

-

Reduced voltage drop

-

Improved thermal management

-

Enhanced mechanical durability

-

Higher reliability under electrical and thermal stress

These benefits are essential for power electronics and industrial systems.

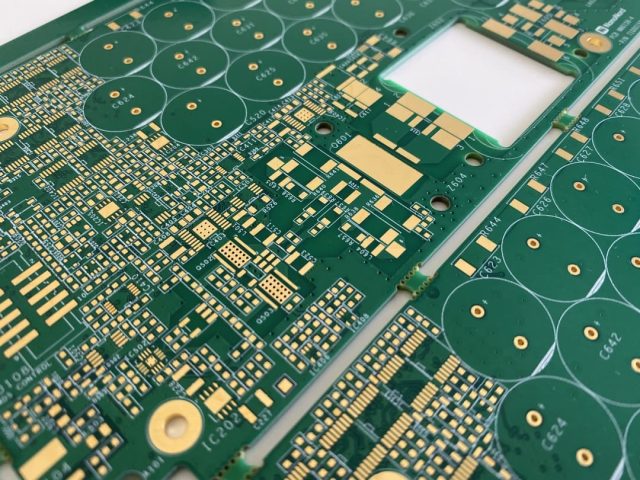

Design Considerations for Heavy Copper PCB

Designing a heavy copper PCB requires special attention:

-

Copper thickness selection based on current requirements

-

Trace width and spacing for heat and current distribution

-

Thermal relief and heat spreading design

-

Via structure for current and thermal transfer

-

Compatibility with surface finishes and soldering processes

Proper design ensures safe and reliable operation.

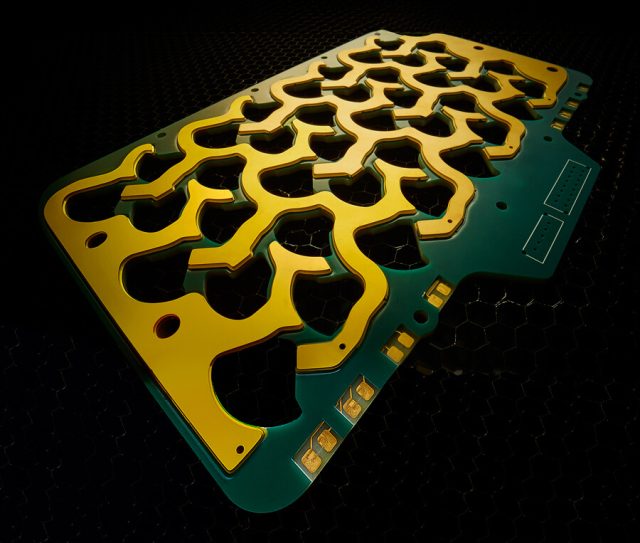

Manufacturing Challenges for Heavy Copper PCB

Manufacturing heavy copper PCBs involves advanced processes:

-

Precise etching control for thick copper layers

-

Advanced plating and lamination techniques

-

Careful drilling and via filling

-

Uniform copper distribution across layers

-

Rigorous electrical and thermal testing

Only experienced manufacturers can deliver consistent heavy copper quality.

Material Options for Heavy Copper PCB

Heavy copper PCBs can be manufactured using:

-

High-Tg FR-4

-

Metal core PCB (MCPCB)

-

Ceramic substrates such as Alumina PCB

-

Hybrid PCB materials for power modules

Material selection depends on power level, thermal requirements, and application environment.

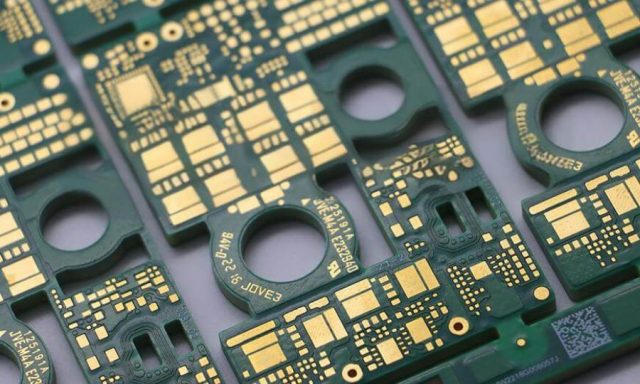

Applications of Heavy Copper PCB

Heavy copper PCBs are widely used in:

-

Power supplies and power converters

-

Automotive power electronics

-

Industrial motor drives

-

Battery management systems (BMS)

-

Semiconductor burn-in and test boards

-

Renewable energy systems

They are essential for high-power and high-reliability applications.

Conclusion

A Heavy Copper PCB is the foundation for high-current and high-power electronic systems, offering excellent electrical performance and thermal reliability. Through proper design and advanced manufacturing, heavy copper PCBs ensure long-term stability in demanding environments.

Choosing a professional heavy copper PCB manufacturer ensures precise copper control, reliable quality, and dependable performance from prototype to mass production.