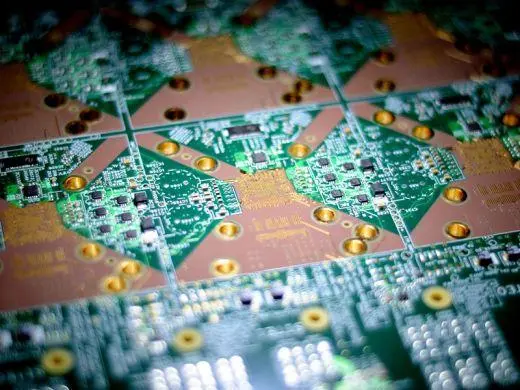

Automated Test Equipment (ATE) PCBs are critical components in high-precision testing systems for semiconductors, modules, and electronic assemblies. Unlike standard PCBs, ATE PCBs must support high-density routing, controlled impedance, fine-pitch interconnects, and reliable signal integrity, ensuring accurate and repeatable test results.

Why ATE PCBs Require Specialized Materials

ATE systems often operate under high-speed digital or RF signals, necessitating PCBs with:

-

Low dielectric loss and stable Dk to maintain signal fidelity

-

High layer count to accommodate dense routing and multiple test channels

-

Fine-pitch via structures for probe and load board connections

-

Mechanical rigidity to withstand repeated probing and handling

Material selection directly affects measurement accuracy, signal integrity, and long-term reliability of the testing system.

Electrical Performance Considerations

High-speed and RF signals in ATE environments require PCBs that deliver:

-

Controlled impedance to match test instrumentation

-

Minimal crosstalk between adjacent channels

-

Consistent phase and propagation delay across signal paths

-

Low insertion loss even at multi-GHz frequencies

ATE PCB designers often use low-loss laminates, BT epoxy, or hybrid materials to achieve predictable performance under repeated stress and high-frequency operation.

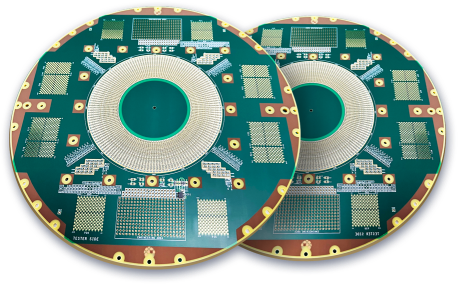

Mechanical and Thermal Reliability

ATE PCBs are exposed to frequent thermal cycles and mechanical stress during device probing. Key engineering considerations include:

-

Layer-to-layer dimensional stability to prevent warpage

-

High Tg materials to survive repeated soldering or reflow processes

-

Reinforced board thickness to maintain flatness under probe pressure

-

Thermal management for high-density boards to avoid overheating

These factors ensure that the ATE PCB maintains long-term reliability and accuracy.

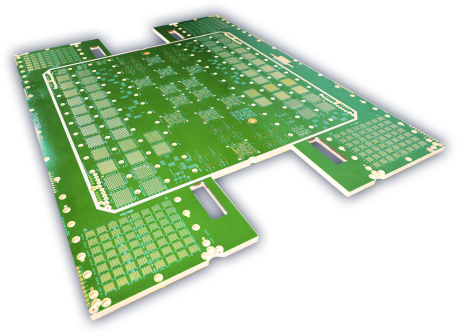

Manufacturing and Supplier Expertise

Partnering with an experienced ATE PCB supplier ensures:

-

Precise layer alignment and controlled lamination processes

-

Fine via formation and high-density routing capability

-

Strict electrical testing for impedance and signal integrity

-

Consistent batch-to-batch performance for high-volume test setups

An expert supplier integrates both material engineering and process control to deliver boards that meet rigorous ATE specifications.

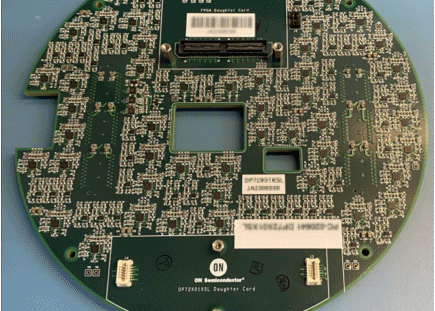

Typical Applications of ATE PCBs

ATE PCBs are widely used in:

-

Semiconductor load boards for wafer-level testing

-

Probe card interposers

-

Functional test boards for ICs, SoCs, and modules

-

High-speed signal test fixtures in RF, 5G, and mmWave systems

-

Automated inspection and calibration systems

In each case, the PCB functions as a precision interface, translating test signals without introducing distortion or error.

Engineering Perspective

Selecting the right ATE PCB supplier is as critical as the PCB design itself. A supplier with expertise in high-density, high-speed, and thermally stable PCB solutions ensures reliable and repeatable test performance, reduces downtime, and enhances the overall quality of the test process.

KKPCB provides ATE PCB design support, material selection guidance, and precision manufacturing services, helping customers develop boards that meet stringent high-speed, high-density, and thermal requirements for automated test equipment.