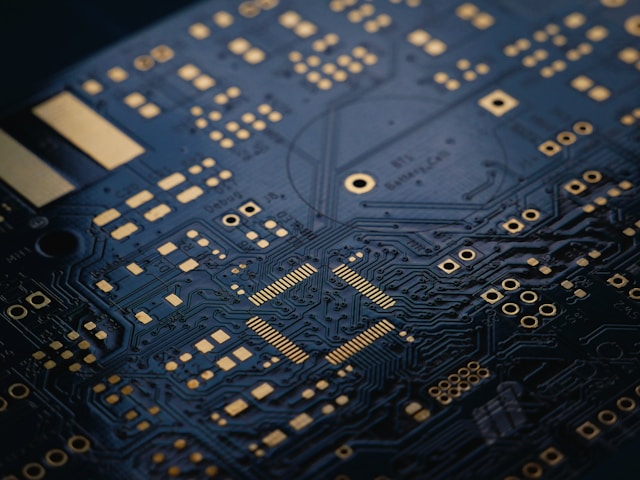

Aluminum Nitride PCB (AlN PCB) is a ceramic substrate technology specifically engineered for electronic systems where power density, thermal stress, and operating temperature exceed the limits of conventional PCB materials. In high-power and high-temperature environments, Aluminum Nitride PCBs serve not only as circuit carriers but as primary thermal management and reliability enablers.

Why Aluminum Nitride PCB Is Selected for High-Power Systems

As power devices such as SiC and GaN semiconductors operate at higher voltages, currents, and switching frequencies, heat generation becomes a dominant system constraint. Traditional FR-4, IMS, or even alumina-based ceramic PCBs struggle to evacuate heat efficiently without introducing thermal bottlenecks.

Aluminum Nitride PCB is chosen when:

-

Continuous power dissipation is high

-

Junction temperature margins are narrow

-

Thermal cycling reliability is critical

-

Electrical insulation must be maintained at elevated temperatures

With thermal conductivity typically above 170 W/m·K, AlN PCBs enable aggressive power scaling without compromising reliability.

Thermal Performance and Heat Flow Control

The defining advantage of an Aluminum Nitride PCB lies in its ability to act as a direct heat conduction path. Unlike organic substrates that rely on copper planes and thermal vias, AlN substrates conduct heat vertically through the ceramic body itself.

Engineering benefits include:

-

Rapid heat transfer from semiconductor junctions to heat sinks

-

Reduced thermal resistance across the substrate

-

Uniform temperature distribution under high load

-

Lower thermal stress on solder joints and metallization

This thermal behavior is critical for power modules, inverters, and high-current driver circuits.

Electrical Insulation and High-Temperature Stability

In addition to thermal performance, Aluminum Nitride PCB materials provide excellent dielectric strength and electrical stability across wide temperature ranges.

Key electrical advantages include:

-

High breakdown voltage with thin dielectric layers

-

Stable electrical insulation at elevated operating temperatures

-

Low dielectric loss suitable for high-frequency switching

-

Reduced risk of partial discharge and insulation degradation

These properties make AlN PCB suitable for high-voltage power electronics and harsh industrial environments.

Mechanical Integrity and Thermal Expansion Matching

Aluminum Nitride exhibits a coefficient of thermal expansion (CTE) closely matched to silicon-based semiconductors. This compatibility significantly reduces mechanical stress during thermal cycling.

Mechanical reliability advantages include:

-

Reduced risk of substrate cracking

-

Improved metallization adhesion

-

Extended lifetime under repeated power cycling

-

Stable dimensional behavior in high-temperature operation

This makes Aluminum Nitride PCB an ideal substrate for long-life power modules and mission-critical electronics.

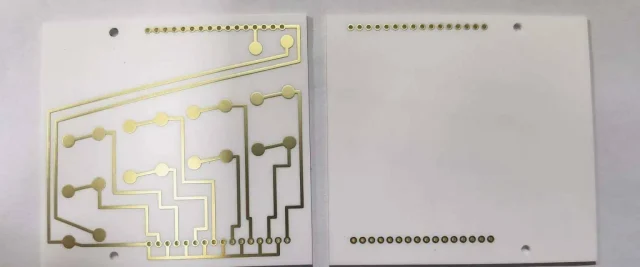

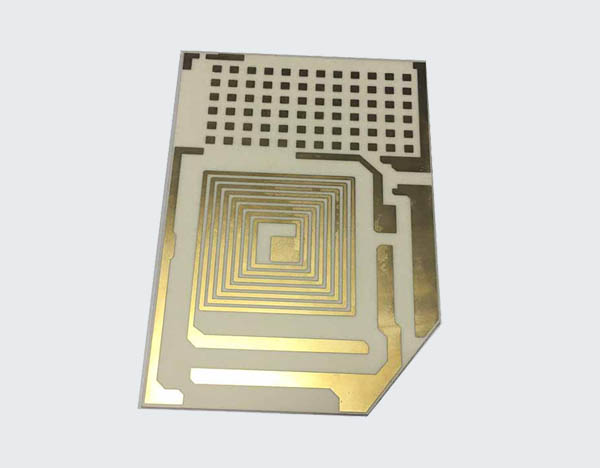

Manufacturing Technologies for Aluminum Nitride PCB

AlN PCBs are typically manufactured using advanced ceramic processes, including:

-

Direct Bonded Copper (DBC) for high-current applications

-

Active Metal Brazing (AMB) for enhanced mechanical robustness

-

Precision metallization for power and control routing

Each process requires strict control of temperature profiles, bonding interfaces, and surface quality to ensure consistent electrical and thermal performance.

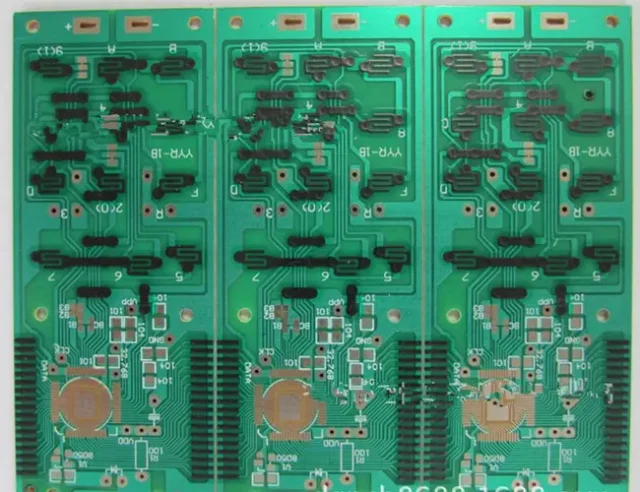

Application Domains

Aluminum Nitride PCBs are widely used in:

-

SiC and GaN power modules

-

EV traction inverters and onboard chargers

-

Renewable energy power converters

-

Aerospace and defense power electronics

-

High-power industrial motor drives

In these applications, Aluminum Nitride PCB technology enables higher power density, higher operating temperature, and longer system lifetime.

Why Aluminum Nitride PCB Is Selected for High-Power Systems

As power devices such as SiC and GaN semiconductors operate at higher voltages, currents, and switching frequencies, heat generation becomes a dominant system constraint. Traditional FR-4, IMS, or even alumina-based ceramic PCBs struggle to evacuate heat efficiently without introducing thermal bottlenecks.

Aluminum Nitride PCB is chosen when:

-

Continuous power dissipation is high

-

Junction temperature margins are narrow

-

Thermal cycling reliability is critical

-

Electrical insulation must be maintained at elevated temperatures

With thermal conductivity typically above 170 W/m·K, AlN PCBs enable aggressive power scaling without compromising reliability.

Thermal Performance and Heat Flow Control

The defining advantage of an Aluminum Nitride PCB lies in its ability to act as a direct heat conduction path. Unlike organic substrates that rely on copper planes and thermal vias, AlN substrates conduct heat vertically through the ceramic body itself.

Engineering benefits include:

-

Rapid heat transfer from semiconductor junctions to heat sinks

-

Reduced thermal resistance across the substrate

-

Uniform temperature distribution under high load

-

Lower thermal stress on solder joints and metallization

This thermal behavior is critical for power modules, inverters, and high-current driver circuits.

Electrical Insulation and High-Temperature Stability

In addition to thermal performance, Aluminum Nitride PCB materials provide excellent dielectric strength and electrical stability across wide temperature ranges.

Key electrical advantages include:

-

High breakdown voltage with thin dielectric layers

-

Stable electrical insulation at elevated operating temperatures

-

Low dielectric loss suitable for high-frequency switching

-

Reduced risk of partial discharge and insulation degradation

These properties make AlN PCB suitable for high-voltage power electronics and harsh industrial environments.

Mechanical Integrity and Thermal Expansion Matching

Aluminum Nitride exhibits a coefficient of thermal expansion (CTE) closely matched to silicon-based semiconductors. This compatibility significantly reduces mechanical stress during thermal cycling.

Mechanical reliability advantages include:

-

Reduced risk of substrate cracking

-

Improved metallization adhesion

-

Extended lifetime under repeated power cycling

-

Stable dimensional behavior in high-temperature operation

This makes Aluminum Nitride PCB an ideal substrate for long-life power modules and mission-critical electronics.

Manufacturing Technologies for Aluminum Nitride PCB

AlN PCBs are typically manufactured using advanced ceramic processes, including:

-

Direct Bonded Copper (DBC) for high-current applications

-

Active Metal Brazing (AMB) for enhanced mechanical robustness

-

Precision metallization for power and control routing

Each process requires strict control of temperature profiles, bonding interfaces, and surface quality to ensure consistent electrical and thermal performance.

Application Domains

Aluminum Nitride PCBs are widely used in:

-

SiC and GaN power modules

-

EV traction inverters and onboard chargers

-

Renewable energy power converters

-

Aerospace and defense power electronics

-

High-power industrial motor drives

In these applications, Aluminum Nitride PCB technology enables higher power density, higher operating temperature, and longer system lifetime.

Engineering Perspective

An Aluminum Nitride PCB is not simply a premium ceramic substrate—it is a system-level thermal and reliability solution. By integrating high thermal conductivity, electrical insulation, and mechanical compatibility into a single platform, AlN PCBs allow engineers to push power electronics beyond the limits of organic and metal-core substrates.

KKPCB supports Aluminum Nitride PCB projects through material selection guidance, DBC/AMB process expertise, and power-oriented layout engineering, ensuring predictable performance in high-power, high-temperature electronic systems.