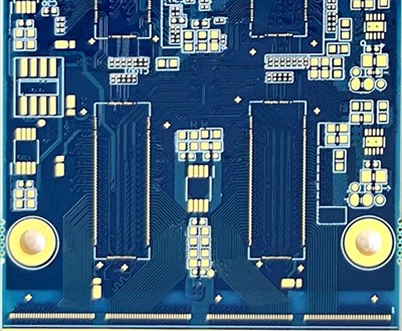

An ATE PCB (Automated Test Equipment PCB) is a specialized circuit board designed to interface with test instrumentation for semiconductor devices, modules, and high-speed systems. A reliable ATE PCB supplier plays a critical role in ensuring signal integrity, mechanical precision, and long-term reliability in high-volume testing environments.

Importance of High-Quality ATE PCBs

ATE PCBs must maintain precise electrical and mechanical characteristics under repeated testing cycles. Variations in impedance, signal loss, or board flatness can introduce errors in measurement, potentially affecting product quality or calibration accuracy.

Key engineering requirements for ATE PCBs include:

-

Stable controlled impedance for high-frequency signals

-

Low insertion loss and minimal crosstalk in dense routing

-

High thermal stability under continuous testing operations

-

Robust mechanical properties to support repeated fixture insertion and removal

Material Selection and Stackup Design

A competent ATE PCB supplier uses materials engineered for high-frequency performance and thermal resilience. Common choices include high TG laminates, low-loss materials, and multi-layer stackups to balance signal integrity with mechanical stability.

Design considerations include:

-

Layer count optimization for dense routing

-

Controlled impedance microstrip and stripline structures

-

Thermal management for high-power test signals

-

Matching coefficient of thermal expansion (CTE) with fixtures and connectors

These strategies ensure the ATE PCB performs consistently across thousands of test cycles.

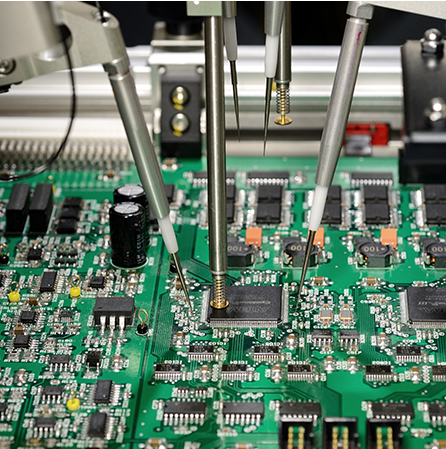

Manufacturing Considerations

Producing high-performance ATE PCBs requires precision manufacturing. Critical factors include:

-

Accurate drilling and plating of vias for reliable connectivity

-

Fine-line etching for high-density test channels

-

Lamination and curing control to prevent warpage

-

Inspection and testing to verify electrical and mechanical parameters

Suppliers must follow strict quality control processes to meet demanding test equipment specifications.

Applications of ATE PCBs

ATE PCBs are widely used in:

-

Semiconductor device testing (ICs, memory modules, RF devices)

-

High-speed digital system verification

-

Power electronics