High Frequency Laminates are specialized PCB substrates engineered to deliver low dielectric loss, stable dielectric constant (Dk), and superior signal integrity in RF, microwave, and high-speed digital applications. Unlike conventional FR-4 materials, high frequency laminates maintain predictable electrical behavior across GHz and mmWave frequencies, enabling advanced communication, radar, and aerospace systems.

Material Characteristics

High frequency PCB laminates, such as Rogers, Taconic, Isola, and Arlon series, are designed for electrical stability and thermal reliability.

Key properties include:

-

Low dissipation factor (Df) to minimize dielectric loss

-

Stable dielectric constant (Dk) across wide frequency ranges

-

High thermal stability (high Tg) for repeated thermal cycling

-

Low moisture absorption for environmental reliability

These characteristics ensure consistent impedance control in microstrip, stripline, and coplanar waveguide configurations.

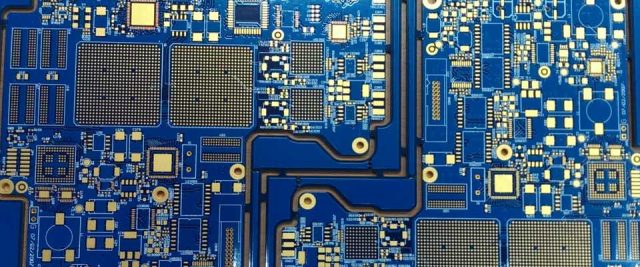

Signal Integrity and Controlled Impedance

In high-frequency circuits, impedance mismatches and dielectric inconsistencies lead to signal reflections, phase distortion, and insertion loss. High frequency laminates provide:

-

Tight impedance control for differential and single-ended signals

-

Minimal signal attenuation in high-speed transmission lines

-

Reduced crosstalk between densely routed traces

-

Stable performance under temperature and frequency variations

This enables robust design for 5G modules, satellite transceivers, radar systems, and high-speed RF front-ends.

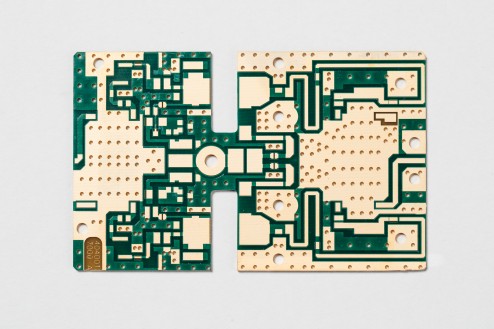

Thermal and Mechanical Performance

High frequency laminates often operate in systems with elevated thermal loads. Key engineering considerations include:

-

High Tg to prevent resin softening during reflow

-

Low coefficient of thermal expansion (CTE) for mechanical stability

-

Compatibility with multi-layer stackups for complex routing

-

Minimal warpage for precision assembly

By addressing thermal and mechanical factors, engineers maintain long-term reliability of high-frequency PCBs.

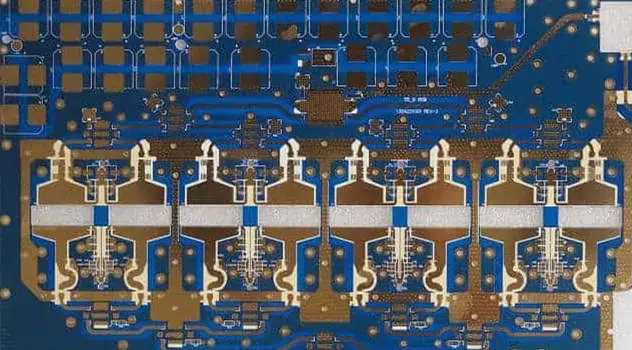

Manufacturing Considerations

Fabricating high frequency laminate PCBs requires specialized techniques:

-

Controlled drilling and plating to maintain microvia and via-in-pad integrity

-

Precision etching for fine-line transmission traces

-

Lamination under strict temperature and pressure control

-

Post-fabrication inspection to verify dielectric properties and layer alignment

These steps ensure repeatable performance in high-frequency applications.

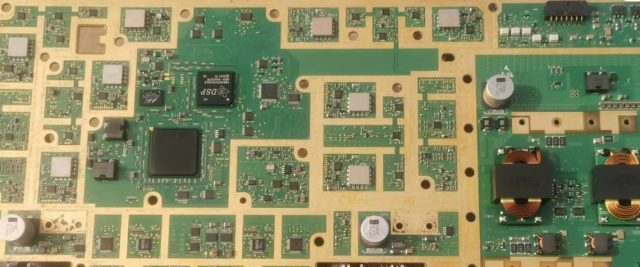

Applications

High frequency laminates are essential in:

-

RF and microwave communication modules

-

Satellite and aerospace electronics

-

High-speed computing backplanes

-

5G and mmWave devices

-

High-performance radar and electronic warfare systems

Engineering Perspective

A High Frequency Laminate PCB is a foundational element for any high-speed or RF system. Material selection, stackup design, and precise manufacturing are critical to achieving low loss, high signal fidelity, and reliable performance. KKPCB provides high-frequency laminate solutions with engineering support for controlled impedance, thermal stability, and multi-layer PCB designs.